A kind of method for growing manganese piezite single crystal pyroelectric material by melt method

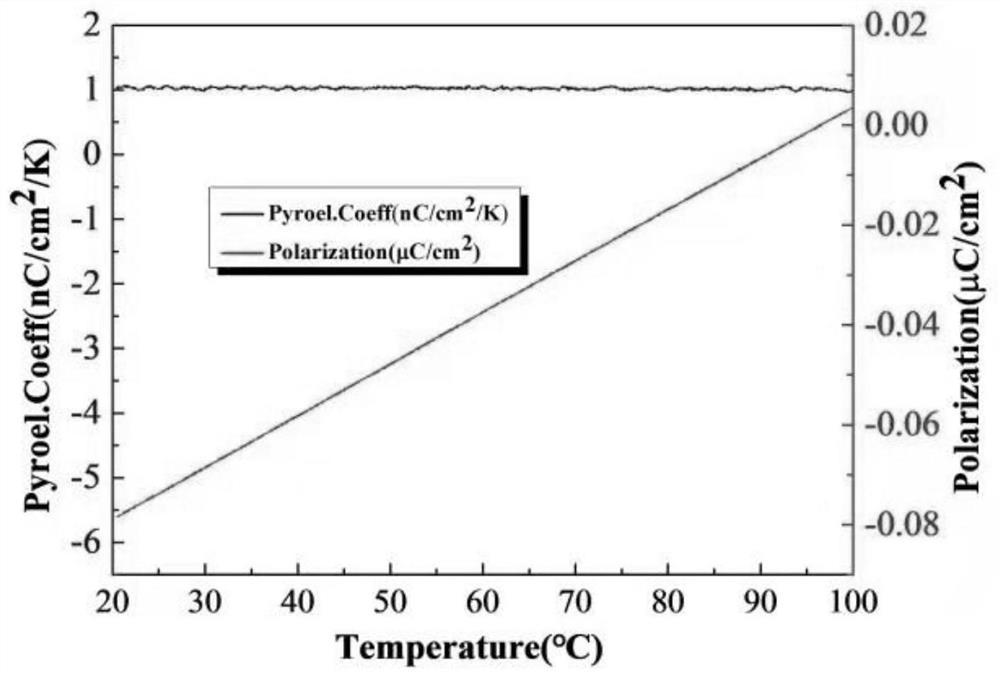

A technology of manganese boronite and pyroelectricity, which is applied in the field of pyroelectric material of manganese boronite single crystal grown by melt method, and can solve the problems of poor pyroelectric performance and cumbersome preparation method of manganese boronite single crystal , to achieve the effect of excellent pyroelectricity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for growing manganese boronite single crystal pyroelectric material by melt method, which includes the following steps:

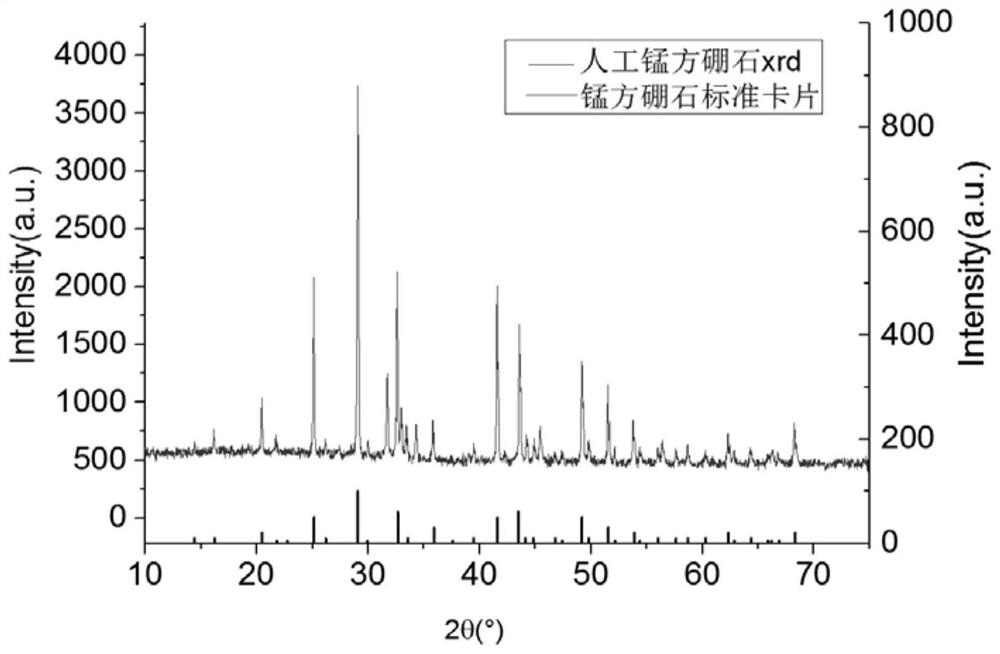

[0027] Step 1. Preparation of manganese boronite crystal powder

[0028] Adopt solid-phase synthesis method, get 11.8716g MnCl 2 ·6H 2 O and 13.34795 g Na 2 B 4 o 7 10H 2 O, the above MnCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2 O were placed in beakers and deionized water was added, and the two were mixed evenly to obtain a solution, the pH of the solution was adjusted to 5-7, and dried in an oven to obtain a solid mixture, which was ground and tabletted , put into a crucible, then put the crucible into a muffle furnace, raise the temperature to 400°C at a heating rate of 5°C / min, and perform calcination. The holding time is 3h, and the furnace is cooled to obtain a solid product. The solid product is ground, Washing with water, filtering, drying and grinding to obtain manganese boronite crystal powder. like ...

Embodiment 2

[0033] This embodiment provides a method for growing manganese boronite single crystal pyroelectric material by melt method, which includes the following steps:

[0034] Step 1. Preparation of manganese boronite crystal powder

[0035] Using solid-phase synthesis method, take 23.7504g MnCl2 6H2O and 26.6959g Na2B4O7 10H2O, the above MnCl 2 ·6H 2 O and Na2B4O7·10H2O were put into a beaker respectively and deionized water was added, and the two were mixed evenly to obtain a solution, the pH of the solution was adjusted to 5-7, and dried in an oven to obtain a solid mixture, and the dried mixture solid Grinding, tableting, putting into a crucible, then putting the crucible into a muffle furnace, heating up to 600°C at a heating rate of 8°C / min, and calcination, holding time of 5h, furnace cooling, to obtain a solid product, solid The product is ground, washed with water, filtered, dried and ground to obtain manganese boronite crystal powder.

[0036] Step 2. Preparation of man...

Embodiment 3

[0039] This embodiment provides a method for growing manganese boronite single crystal pyroelectric material by melt method, which includes the following steps:

[0040] Step 1, prepare manganese boronite crystal powder by solid-phase synthesis method, take 35.6256gMnCl 2 ·6H 2 O and 40.0439g Na 2 B 4 o 7 10H 2 O, the above MnCl 2 ·6H 2 O and Na 2 B 4 o 7 10H 2O were placed in beakers and deionized water was added, and the two were mixed evenly to obtain a solution, and the pH of the solution was adjusted to 5-7, and dried in an oven to obtain a solid mixture, which was ground and pressed into tablets , put into the crucible, then put the crucible into the muffle furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and carry out calcination. The holding time is 7h, and the furnace is cooled to obtain a solid product. The solid product is ground, Washing with water, filtering, drying and grinding to obtain manganese boronite crystal powder.

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com