Construction method for super-large-section tunnel step of soft rock in karst cave development stratum

A technology with extra-large cross-section and construction method, which is applied in tunnels, tunnel linings, underground chambers, etc., and can solve problems such as increased difficulty in implementing karst cave treatment measures, inoperability of large machinery, and low degree of mechanization support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

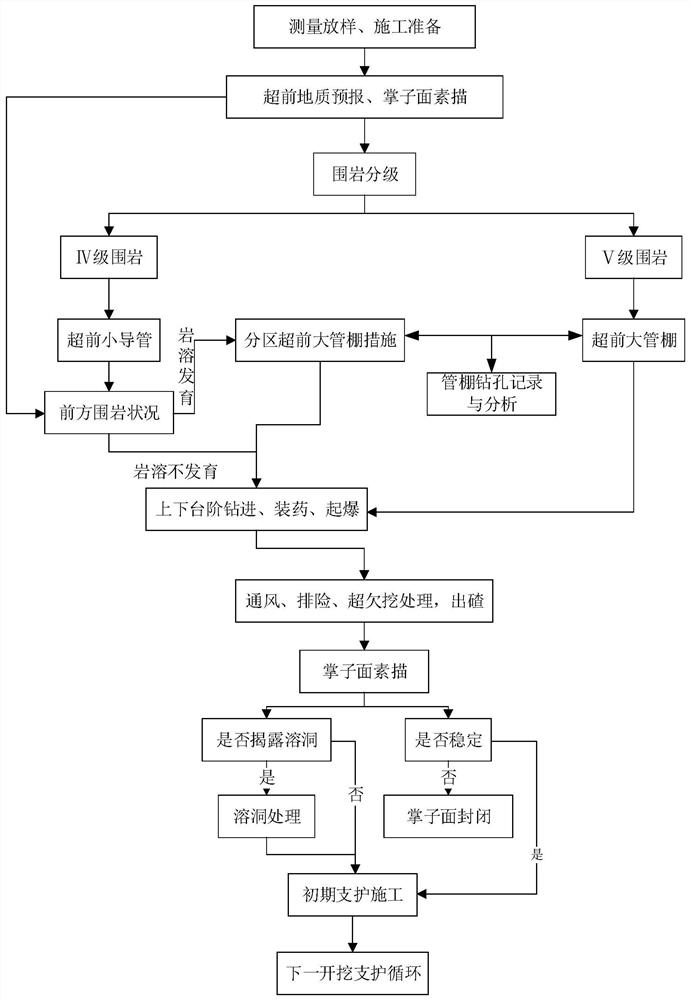

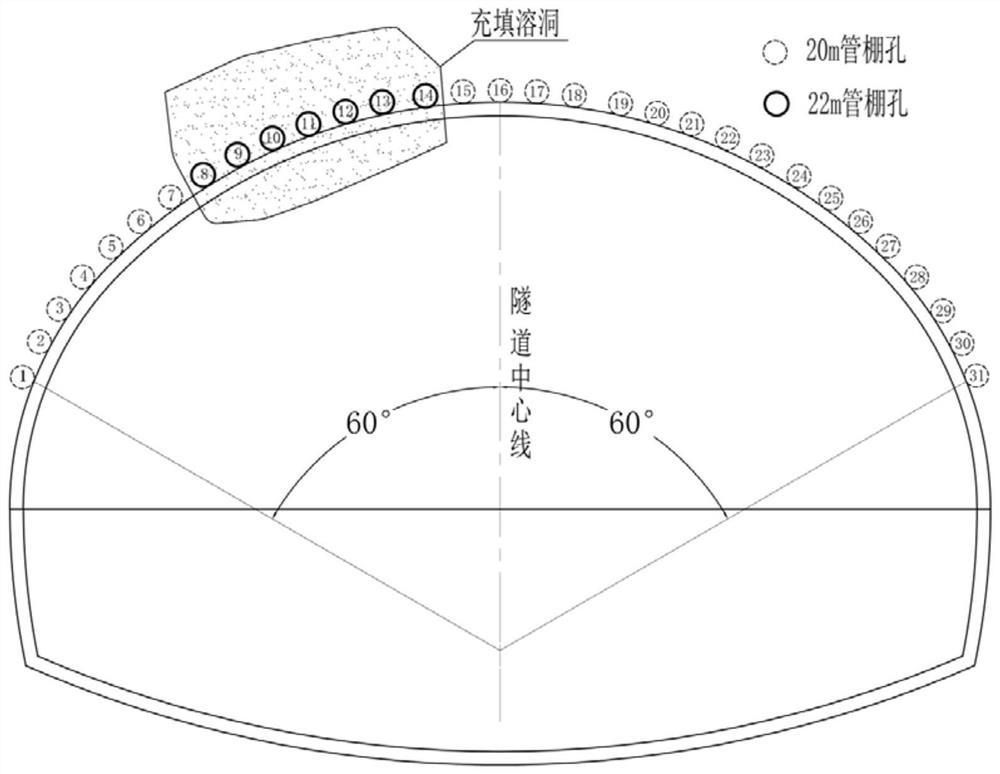

[0075] Embodiment 1: This embodiment is a tunnel with three lanes and three centers, and the cross-sectional area of the tunnel is about 167m 2 , the technical scheme of construction method comprises the following steps:

[0076] Step (1): Use geological radar to detect the range 30m in front of the face of the tunnel. The detection results show that the lithology of the face is soluble rock, the rock mass is relatively hard, the rock mass is broken, and the groundwater is not developed; the arch survey line The map shows that the radar wave reflection is strong in the 9-15m section in front of the tunnel face, and a large-scale karst cave may be developed. The groundwater in the measured section is not developed, and the surrounding rock is grade Ⅴ.

[0077] Step (2): According to the condition of the surrounding rock and the development of the karst cave, it is judged that the advanced support adopts the advanced large pipe shed. The design length of the advanced large pip...

Embodiment 2

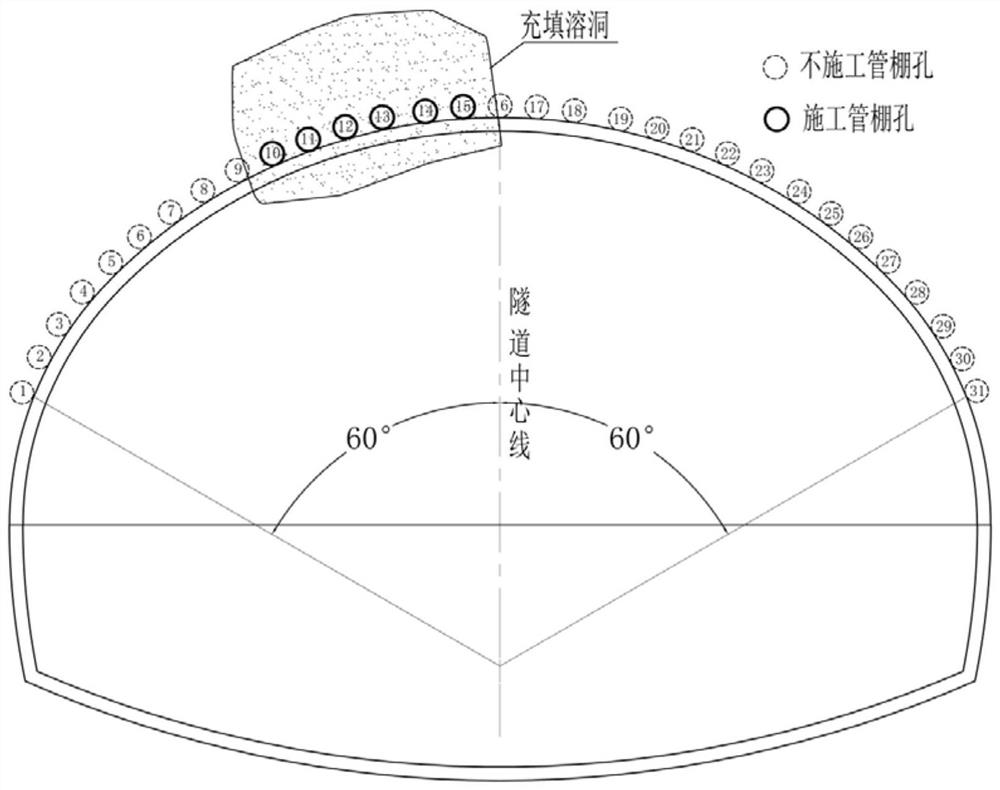

[0083] Embodiment two: the present embodiment is a three-lane three-center circle tunnel, and the cross-sectional area of the tunnel is about 167m 2 , the technical scheme of construction method comprises the following steps:

[0084] Step (1): Using geological radar to detect the area 30m in front of the face of the tunnel, the detection results show that the lithology of the face is soluble rock, the rock is relatively hard, the rock mass is broken, and the groundwater is not developed; the map shows that the measured section is basically maintained At present, the condition of the face is that the rock quality is relatively hard, the rock mass is broken, and there is no obvious water body, and the surrounding rock grade is V grade.

[0085] Step (2): According to the condition of the surrounding rock and the development of the karst cave, it is judged that the advanced support adopts the advanced large pipe shed. The design length of the advanced large pipe shed is 20m, a...

Embodiment 3

[0091] Embodiment three: the present embodiment is a three-lane three-center circle tunnel, and the cross-sectional area of the tunnel is about 167m 2 , the technical scheme of construction method comprises the following steps:

[0092] Step (1): Using geological radar to detect the area 30m in front of the face of the tunnel, the detection results show that the lithology of the face is soluble rock, the rock is relatively hard, the rock mass is relatively broken, and the groundwater is not developed; the survey line map of the vault shows There is a section with strong radar reflection in the 3-9m section ahead, and it is speculated that there is a large-scale dissolved cavity in this section; the sidewall line map shows that there is a section with strong radar reflection in the section 2m-5m ahead, and it is speculated that there may be a weak interlayer or a dissolved cavity in this section. The stability of the surrounding rock is average, and the grade of the surroundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com