Range hood and control method thereof

A range hood and control method technology, applied in the direction of oil fume removal, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as poor removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

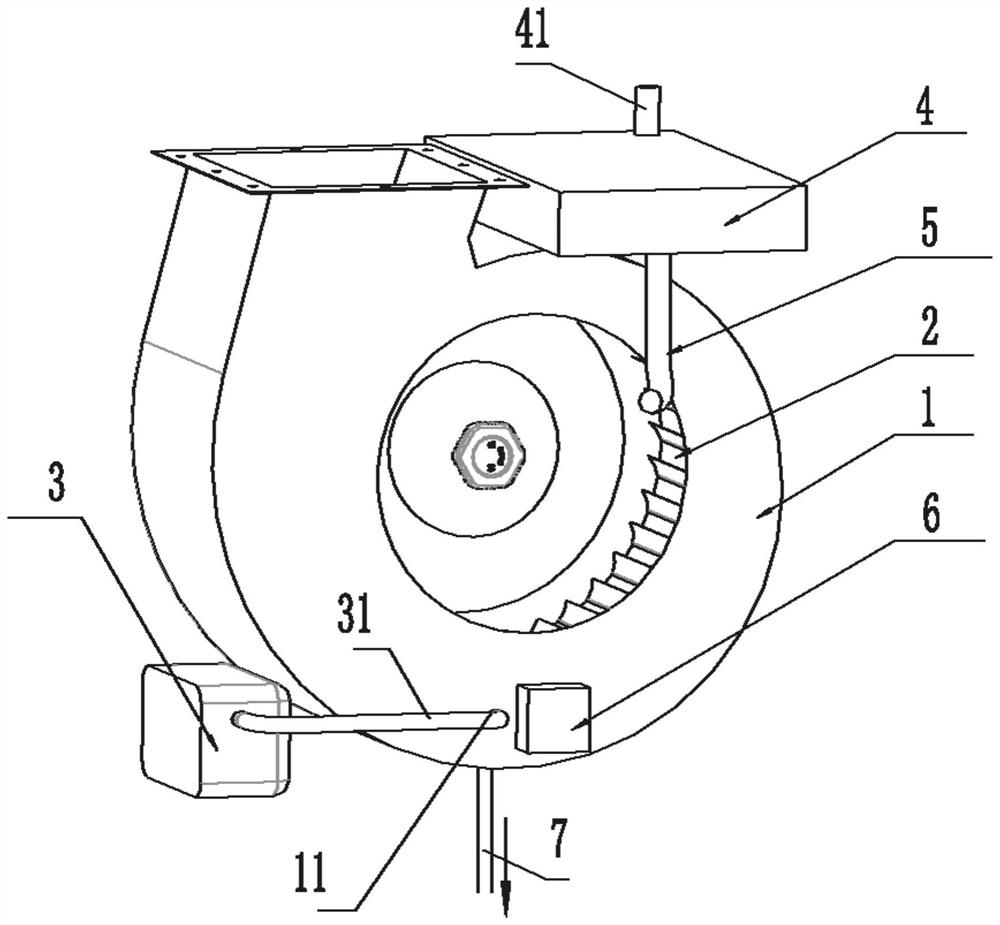

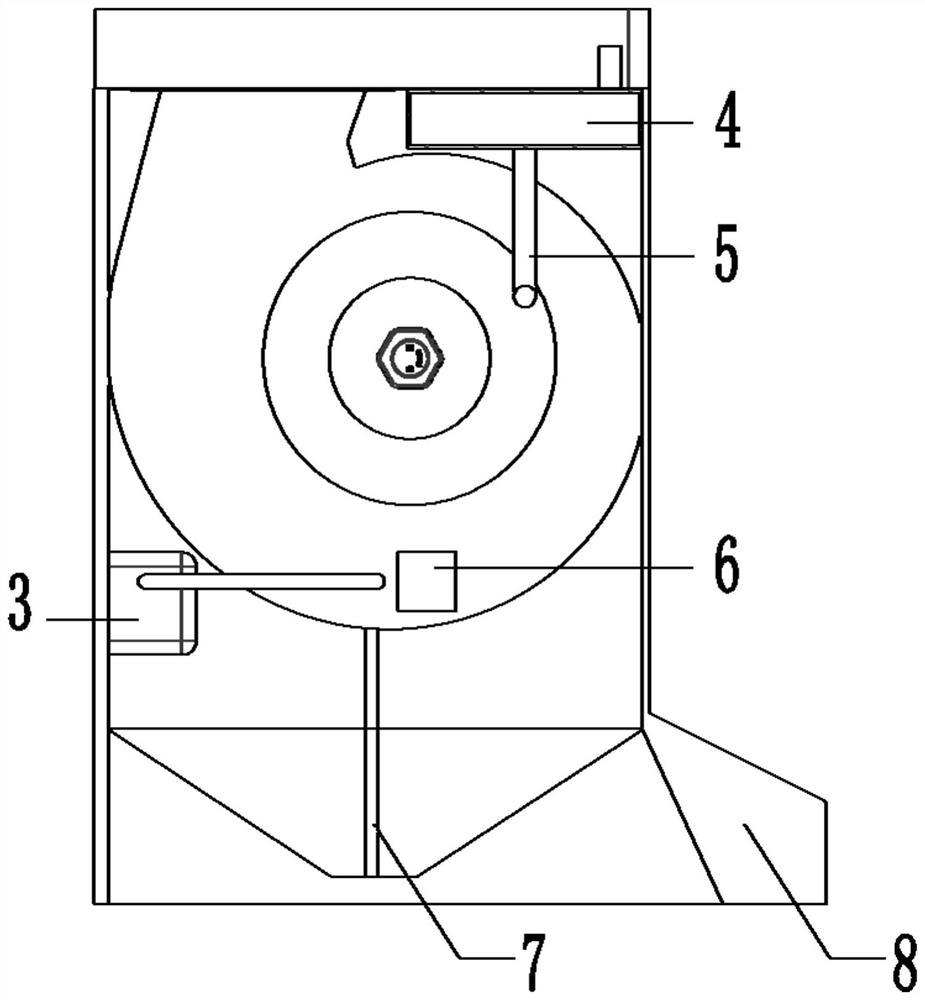

[0036] This embodiment provides a range hood, such as Figure 1-Figure 2 shown, including:

[0037] The housing 1 is provided with a wind wheel 2 inside, and the housing 1 is provided with an air inlet 11;

[0038] Specifically, the casing 1 includes a volute assembly, and a wind wheel 2 is arranged at the center of the volute assembly. After the wind wheel 2 is activated, the external oil is introduced into the volute assembly, and driven by the volute assembly, Exhausted to the outside world.

[0039] In this embodiment, a fume collecting hood 8 is provided under the housing 1, such as figure 2 As shown, the oil fume inhaled through the fume collecting hood 8 will further enter the casing 1 .

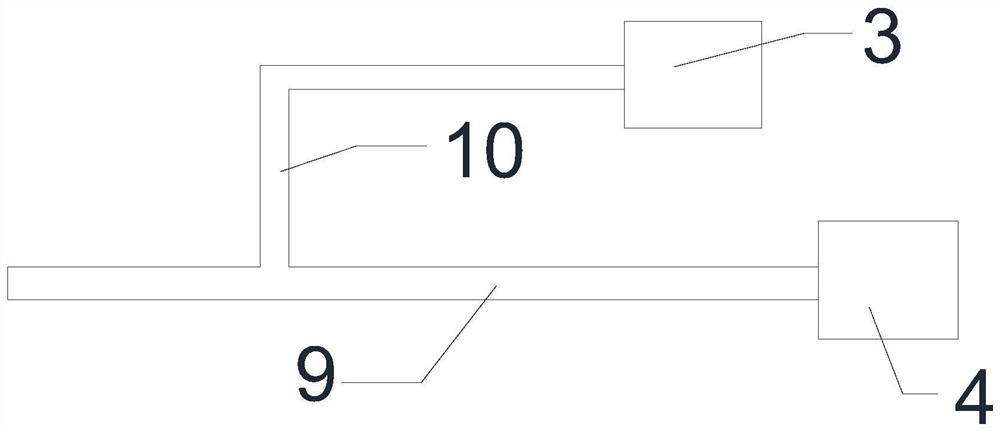

[0040] A micro-nano-bubble generating device 3, the micro-nano-bubble generating device 3 communicates with the air inlet 11;

[0041] Specifically, the shape of the air inlet 11 is not limited, as long as the operation of introducing micro-nano bubbles can be realized. Such as ...

Embodiment 2

[0057] This embodiment provides a method for controlling a range hood. The range hood is provided with a water tank and a micro-nano bubble generating device, including the following steps:

[0058] Control the start-up of the micro-nano bubble generating device, and feed the micro-nano bubbles into the wind wheel;

[0059] controlling the water tank to inject water into the wind wheel;

[0060] The wind wheel is controlled to rotate at the first rotational speed.

[0061] Specifically, the order of the above steps is not limited, and the work order of different steps can be adjusted according to actual working conditions.

[0062] Through the water injection operation and the operation of introducing micro-nano bubbles, micro-nano bubble water can be formed in the volute assembly. When the wind wheel is started, the resistance of the micro-nano bubble water itself to the wind wheel is greater, and the rotation of the wind wheel can make the micro-nano bubble water The conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com