Transfer mechanism for a split-cycle engine

An engine and transmission cavity technology, applied in the field of split cycle engines, can solve problems such as reducing efficiency, reducing compression ratio, and exhaust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

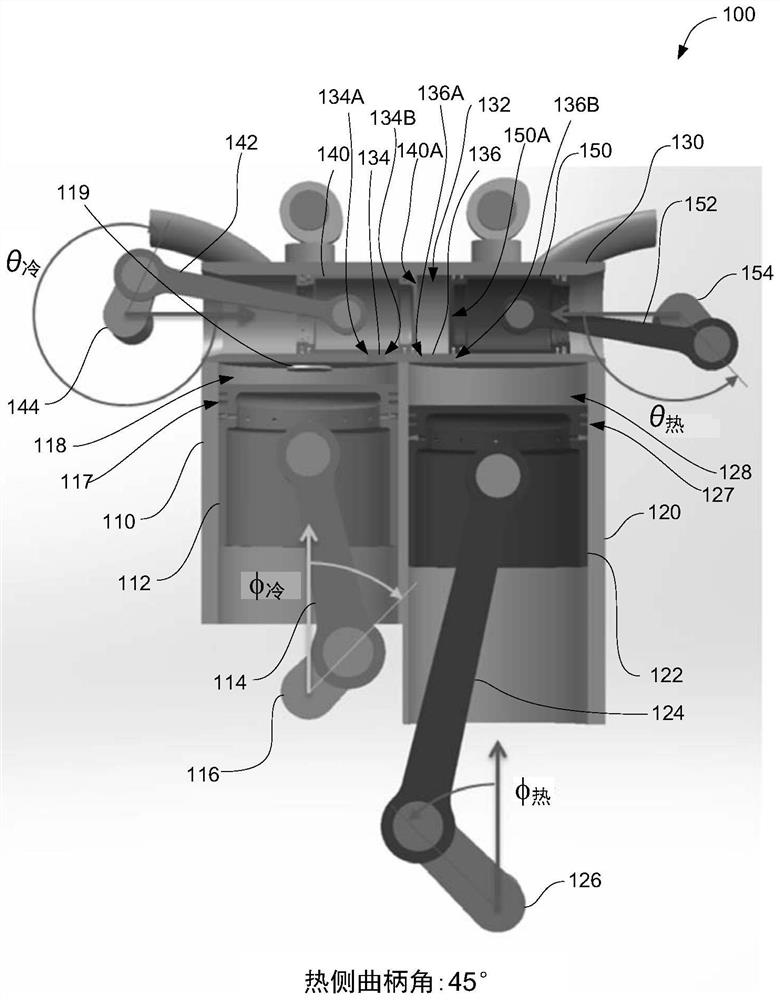

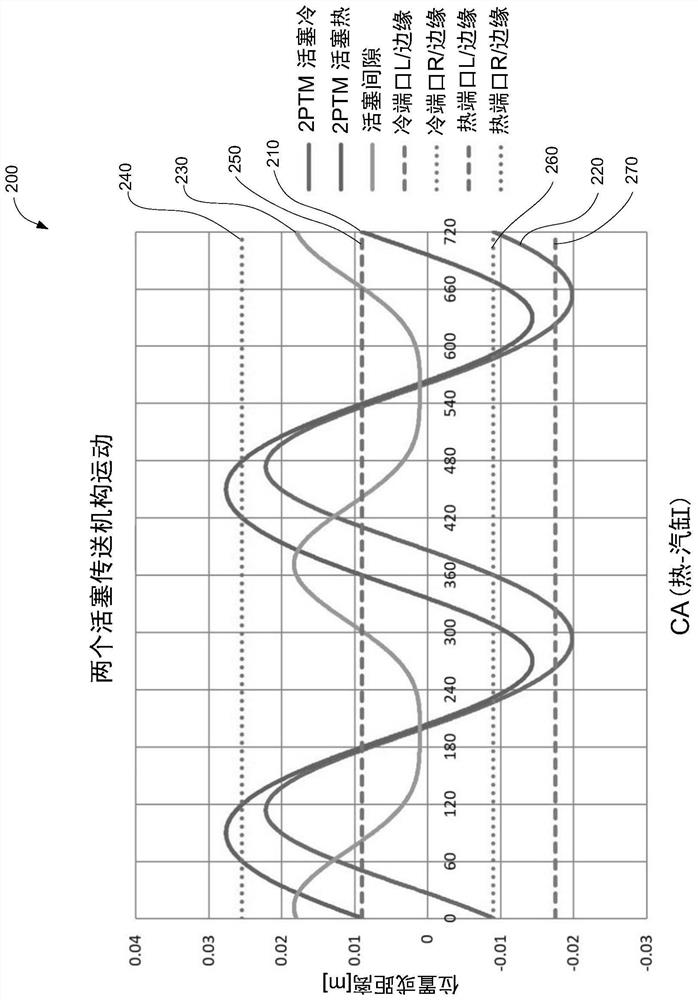

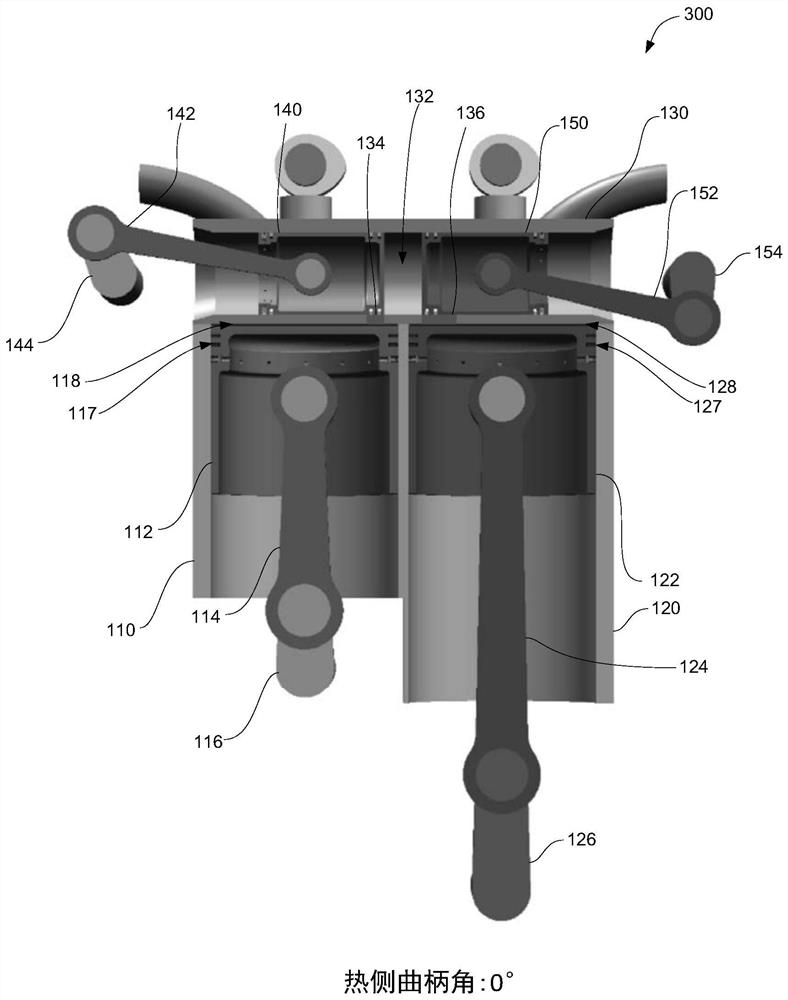

[0039] In view of the above-mentioned inherent disadvantages of known types of internal combustion engines now existing in the prior art, the embodiments described herein include split-cycle internal combustion engines having different cylinders. In some embodiments, the split-cycle internal combustion engines described herein having different cylinders more efficiently convert fuel energy into mechanical work, better control the amount of EGR, and enable reduced EGR in split-cycle engines. In some embodiments, the transfer cylinder facilitates more efficient and reliable transfer of working fluid from the compression chamber to the expansion chamber. In some embodiments, the transfer chamber includes two pistons that are relatively (e.g., laterally within the transfer chamber) movable to selectively fluidly couple the transfer chamber with the compression and expansion chambers (e.g., Movement of the two pistons causes the transfer chamber to be fluidly coupled to neither, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com