In-situ laser cleaning auxiliary tool for airplane

A laser cleaning and auxiliary tooling technology, which is applied in the field of laser cleaning, can solve problems such as surface damage, inability to meet high-quality cleaning and processing requirements, and inability to guarantee the consistency of processing results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

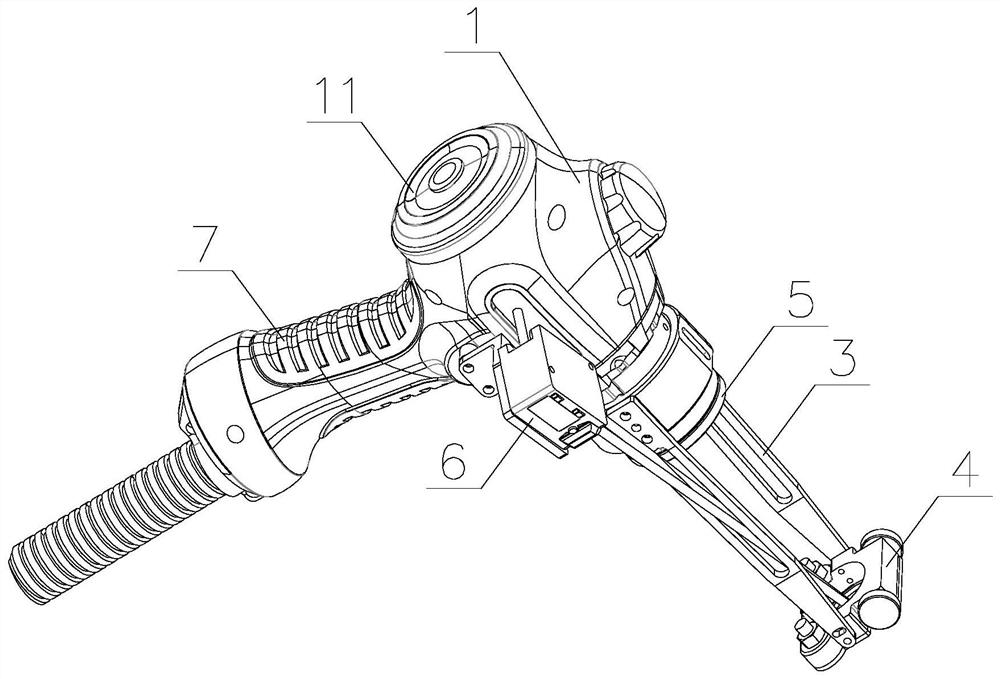

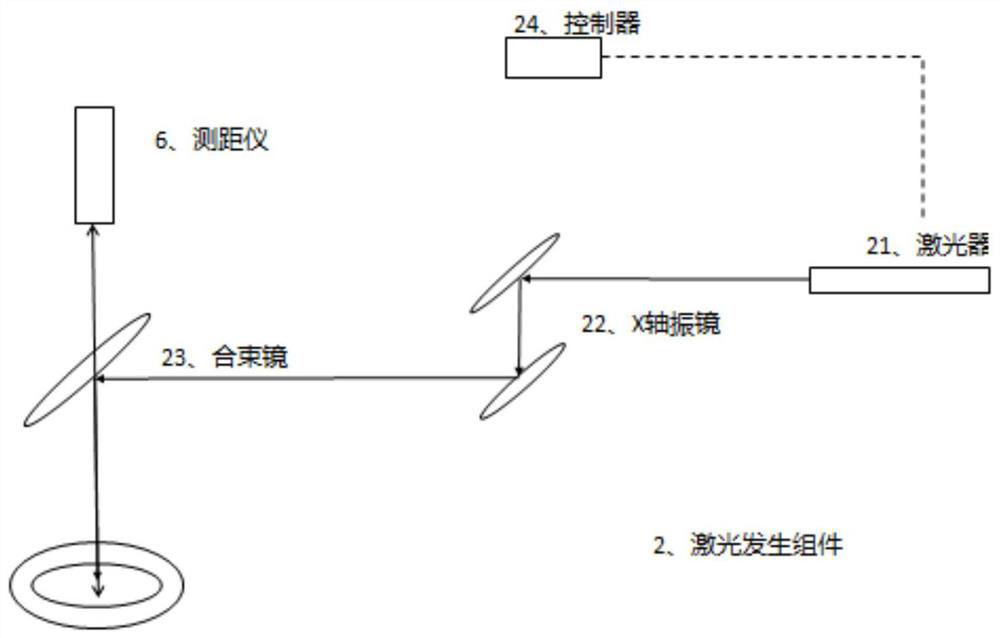

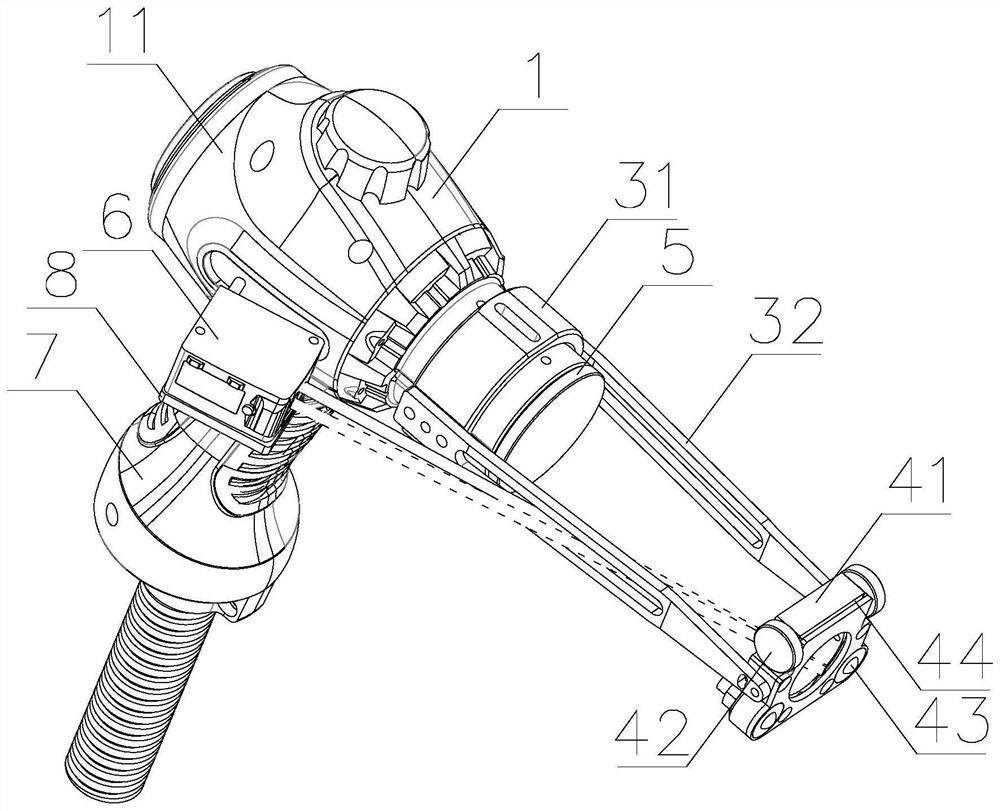

[0039] Such as figure 1 As shown, an aircraft in-situ laser cleaning auxiliary tooling includes a tooling body 1 with a hollow interior, a laser generating component 2, a support component 3 hollowed out in the middle, and a walking component 4. One end of the tooling body 1 is provided with a The laser generating assembly 2 is arranged in the tool body 1, and one end of the support assembly 3 is connected to the outer wall of the end of the tool body 1 where the light output hole is provided. The support assembly 3 The other end of the walking assembly 4 is installed, the middle part of the walking assembly 4 is provided with a through hole for the laser to pass through and irradiate the surface of the cleaning obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com