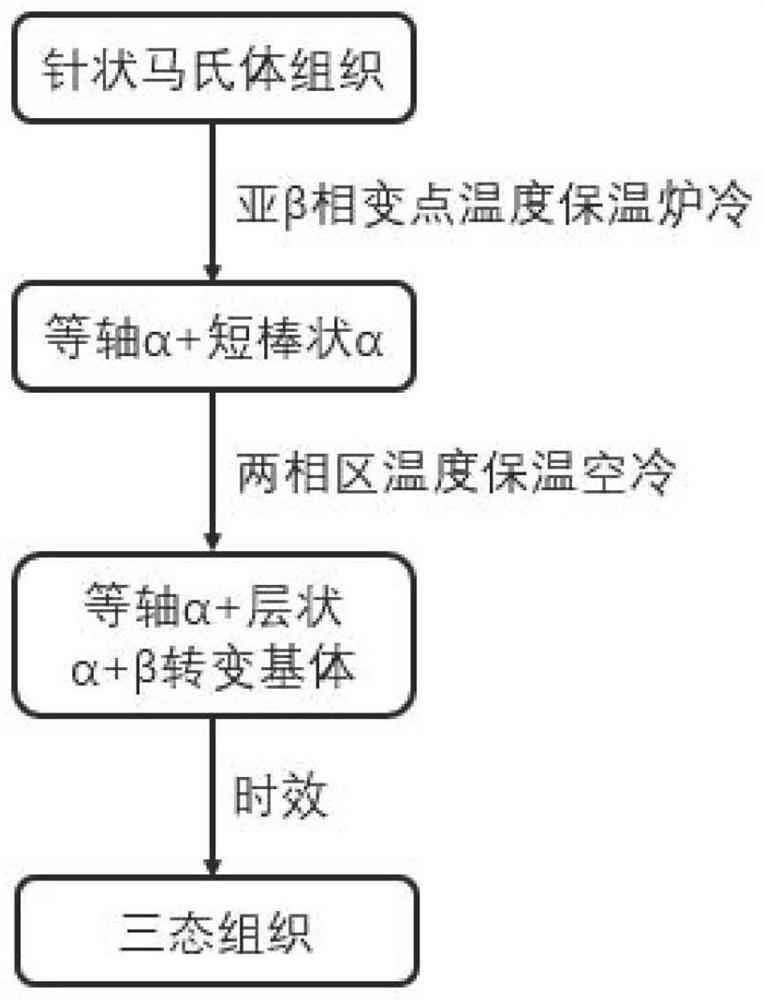

Heat treatment method for obtaining tri-state structure in SLM forming titanium alloy

A heat treatment furnace, β titanium alloy technology, applied in the direction of process efficiency improvement, additive manufacturing, energy efficiency improvement, etc., can solve the problems of excellent three-state structure, failure to obtain mechanical properties of titanium alloy, etc., to improve the strength-plasticity mismatch. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

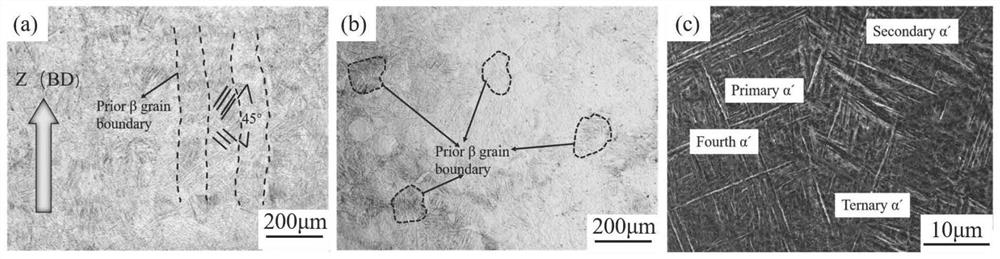

[0030] Using TA15 (Ti-6Al-2Zr-1Mo-1V) powder particles with an average particle size of 43.6μm and the composition as shown in the parameter attached table as the raw material for molding, according to the process parameters shown in the parameter attached table to form a rod with a size specification of Φ12mmⅹ83mm material.

[0031] Parameter Schedule I

[0032]

[0033] Parameter Schedule II

[0034]

[0035] Use laser selective melting equipment to print TA15 titanium alloy powder (phase transition point temperature 995°C), and print it into a bar of Φ12mmⅹ83mm. Wire cutting is used to separate the bar from the substrate, and then the bar is placed in a vacuum heat treatment furnace for heat treatment.

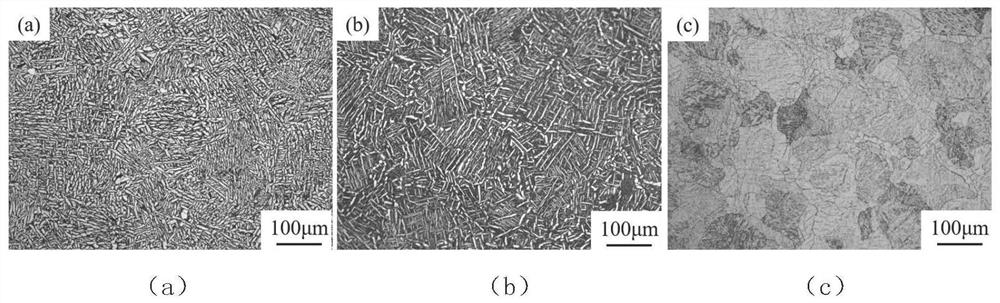

[0036] First, heat the bar to 970°C at a heating rate of 10°C / min and keep it for 1.5h, turn off the heating program, and cool down to room temperature with the furnace; then heat the bar for one heat treatment to 930°C at the same heating rate for 2h, take it out ...

Embodiment 2

[0039] Using TA15 (Ti-6Al-2Zr-1Mo-1V) powder particles with an average particle size of 43.6μm and the composition as shown in the parameter attached table as the raw material for molding, according to the process parameters shown in the parameter attached table to form a rod with a size specification of Φ12mmⅹ83mm material.

[0040] Parameter Schedule I

[0041]

[0042] Parameter Schedule II

[0043]

[0044] Use laser selective melting equipment to print TA15 titanium alloy powder (phase transition point temperature 995°C), and print it into a bar of Φ12mmⅹ83mm. Wire cutting is used to separate the bar from the substrate, and then the bar is placed in a vacuum heat treatment furnace for heat treatment.

[0045] First, heat the bar to 970°C at a heating rate of 10°C / min for 1 hour, turn off the heating program, and cool down to room temperature with the furnace; then heat the once-heated bar to 930°C at the same heating rate for 3 hours, and take out the sample Expo...

Embodiment 3

[0048] Using TA15 (Ti-6Al-2Zr-1Mo-1V) powder particles with an average particle size of 43.6μm and the composition as shown in the parameter attached table as the raw material for molding, according to the process parameters shown in the parameter attached table to form a rod with a size specification of Φ12mmⅹ83mm material.

[0049] Parameter Schedule I

[0050]

[0051] Parameter Schedule II

[0052]

[0053] Use laser selective melting equipment to print TA15 titanium alloy powder (phase transition point temperature 995°C), and print it into a bar of Φ12mmⅹ83mm. Wire cutting is used to separate the bar from the substrate, and then the bar is placed in a vacuum heat treatment furnace for heat treatment.

[0054] First, heat the bar to 970°C at a heating rate of 10°C / min for 2 hours, turn off the heating program, and cool down to room temperature with the furnace; then heat the bar for one heat treatment to 950°C at the same heating rate for 3 hours, and take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com