A kind of nicocr-based medium-entropy alloy with excellent strength-plasticity matching and its preparation method

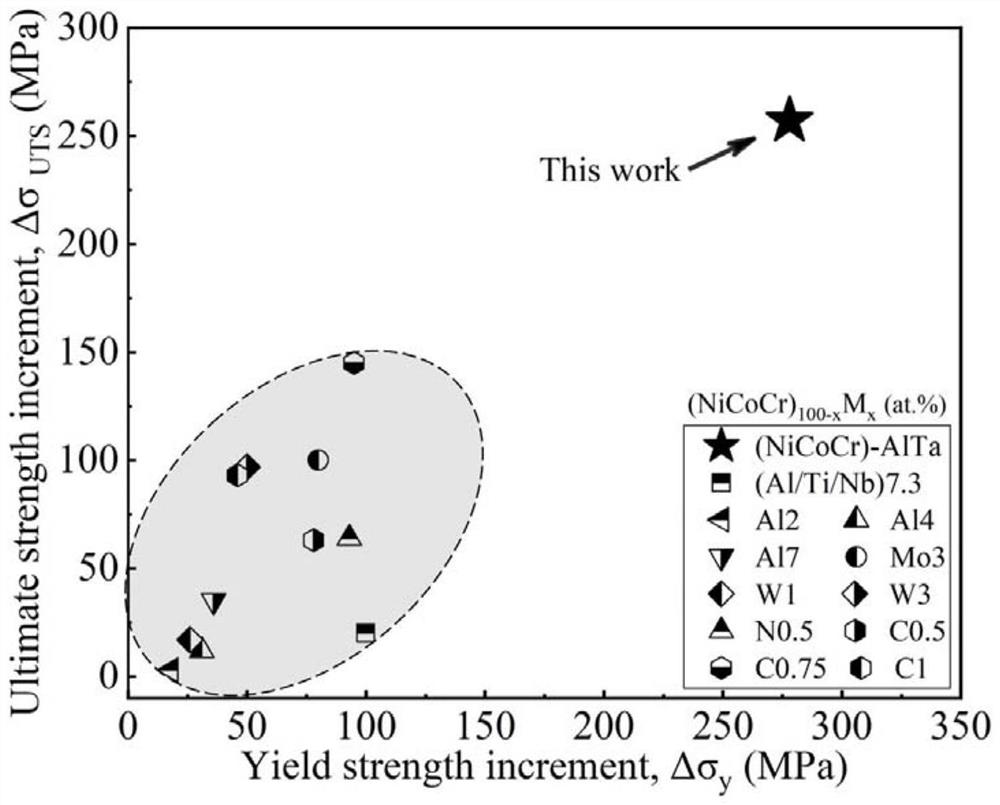

A technology of entropy alloying and strength, applied in the field of entropy alloying and preparation in NiCoCr-based medium, can solve the problems of limited yield strength, etc., and achieve the effects of increased twinning content, significant solid solution strengthening effect, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned NiCoCr-AlTa series medium entropy alloy comprises the following steps:

[0030] Step 1. According to atomic percentage, uniformly mix metal particles of 29-33% Ni, 29-33% Co, 29-33% Cr, 4-8% Al and 1.0-3.0% Ta.

[0031] The weight of raw materials is accurate to 0.01g when weighing, and then the alloy is smelted by vacuum arc melting method.

[0032] During the smelting process, first vacuum to 5Pa and then pass high-purity argon gas and then evacuate. Repeat the furnace washing three times to ensure a high-purity vacuum environment. The smelting induction current is 400-500A. The alloy smelting process is accompanied by electromagnetic stirring and repeated remelting 5 times to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0033] Step 2, the alloy ingot is homogenized at 1150-1250°C;

[0034] Step 3, cold rolling at room temperature, the amount of defo...

Embodiment 1

[0037] A kind of preparation method of NiCoCr-AlTa system entropy alloy, comprises the following steps:

[0038] Step 1. In atomic percentage, uniformly mix metal particles of 29% Ni, 31% Co, 33% Cr, 4% Al and 3% Ta.

[0039] During the smelting process, first vacuum to 5Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 400A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 5 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0040] Step 2, the alloy ingot is homogenized at 1150°C;

[0041] Step 3, cold rolling at room temperature, the amount of deformation is controlled at 50%;

[0042] In step 4, a single-phase fcc alloy is obtained after recrystallization annealing at 1100°C.

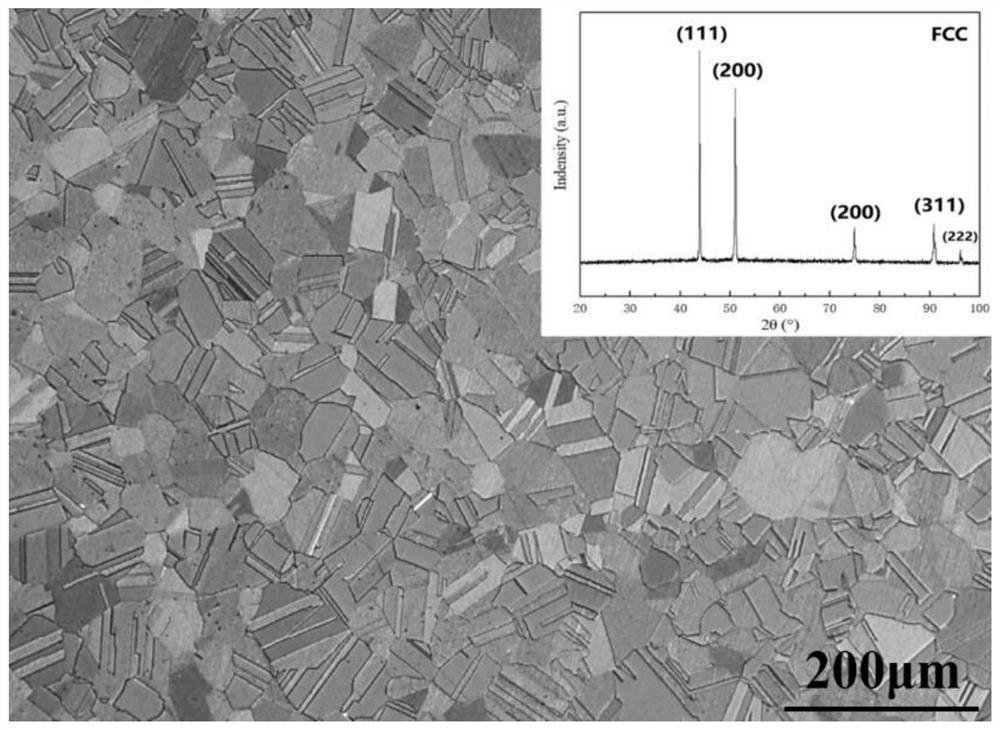

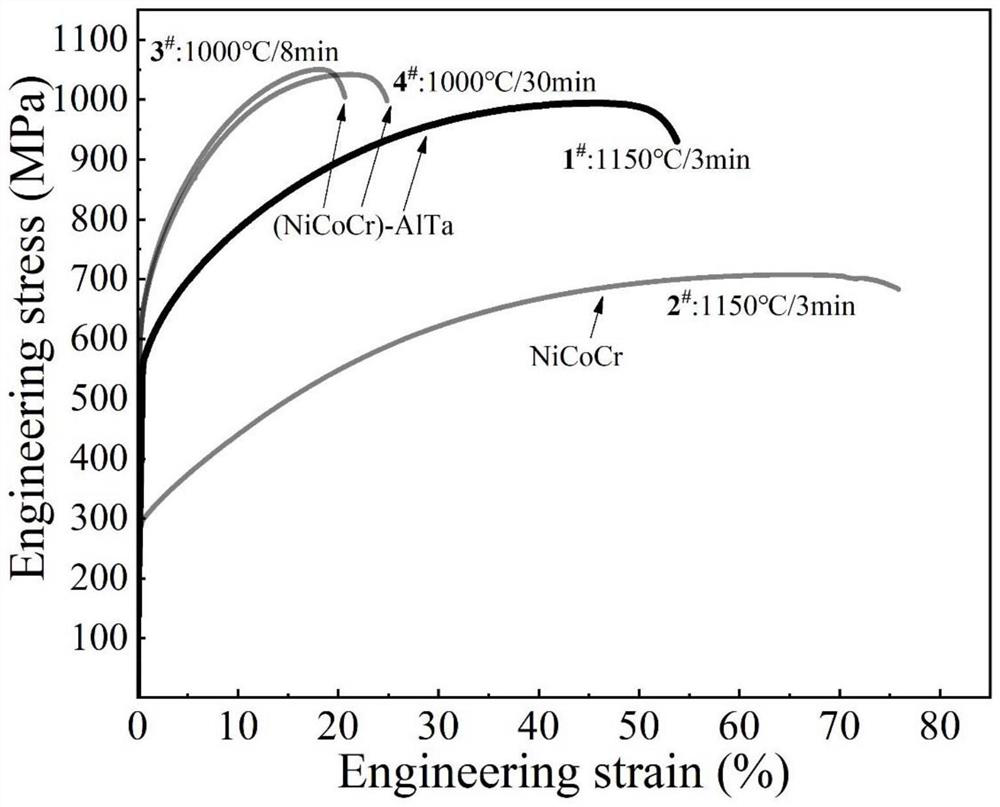

[0043] In the single-phase fcc structure, the equiaxed...

Embodiment 2

[0045] A kind of preparation method of NiCoCr-AlTa system entropy alloy, comprises the following steps:

[0046] Step 1. In atomic percentage, uniformly mix metal particles of 31% Ni, 29% Co, 31% Cr, 7% Al and 2.0% Ta.

[0047]During the smelting process, first vacuum to 5Pa, then pass high-purity argon gas and then evacuate, repeat the furnace washing three times to ensure a high-purity vacuum environment, the smelting induction current is 450A, the alloy smelting process is accompanied by electromagnetic stirring, and repeated remelting 6 times , to ensure the uniformity of the composition, and finally cooled in a water-cooled copper crucible to obtain an ingot;

[0048] Step 2, the alloy ingot is homogenized at 1200°C;

[0049] Step 3, cold rolling at room temperature, the amount of deformation is controlled at 65%;

[0050] Step 4: After recrystallization annealing at 1150° C., a single-phase fcc alloy is obtained.

[0051] In the single-phase fcc structure, the equiaxe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com