Rib titanium alloy hollow structural part and preparation method thereof

A hollow structure, titanium alloy technology, applied in building elements, sheets/boards, weight reduction, etc., to achieve the effect of small deformation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described below in conjunction with the accompanying drawings, but it is not used to limit the scope of the present invention.

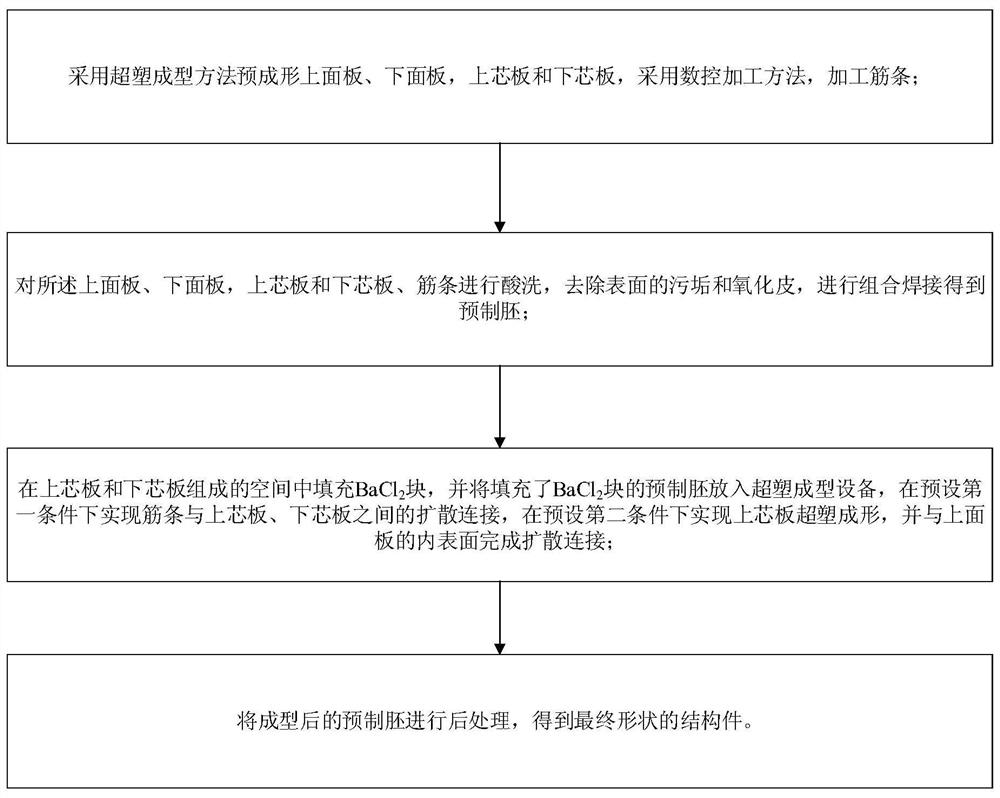

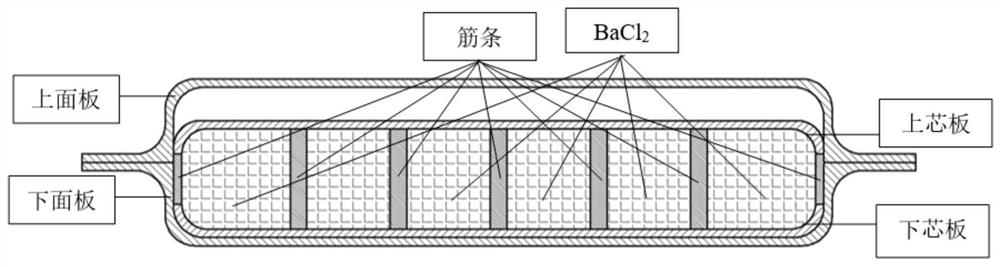

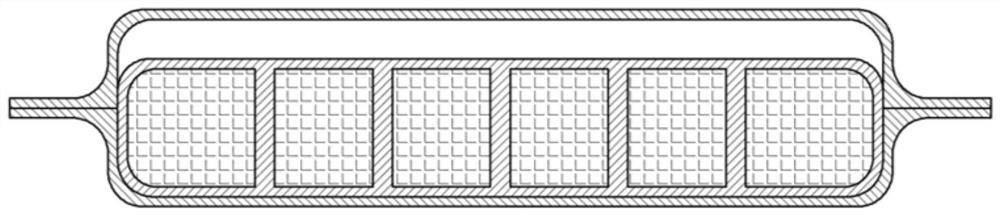

[0034] see figure 1 It is a flow chart of a method for preparing a ribbed titanium alloy hollow structural part of the present invention, including:

[0035] S1: The upper panel, the lower panel, the upper core plate and the lower core plate are preformed by the superplastic forming method, and the ribs are processed by the numerical control processing method.

[0036] In order to avoid ribs from breaking during the forming process, two outer skin structures (ie, upper panel and lower panel) are superplastically formed. Then two core plates are formed by superplastic forming, and the ribs are processed by numerical control, but the height of the ribs is lower than the height of the ribs after actual forming.

[0037] S2: Pickling the upper panel, lower panel, upper and lower core panels, and ribs to remove surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com