3D printing wireless transmission control device and method with storage, sharing and calling functions

A 3D printing and wireless transmission technology, applied in the field of 3D printing, can solve problems such as time-consuming, labor-intensive, large energy consumption, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

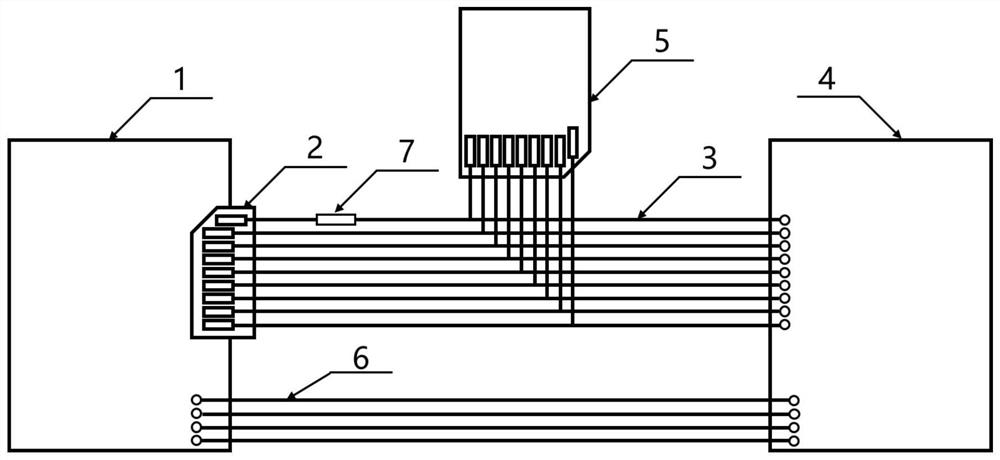

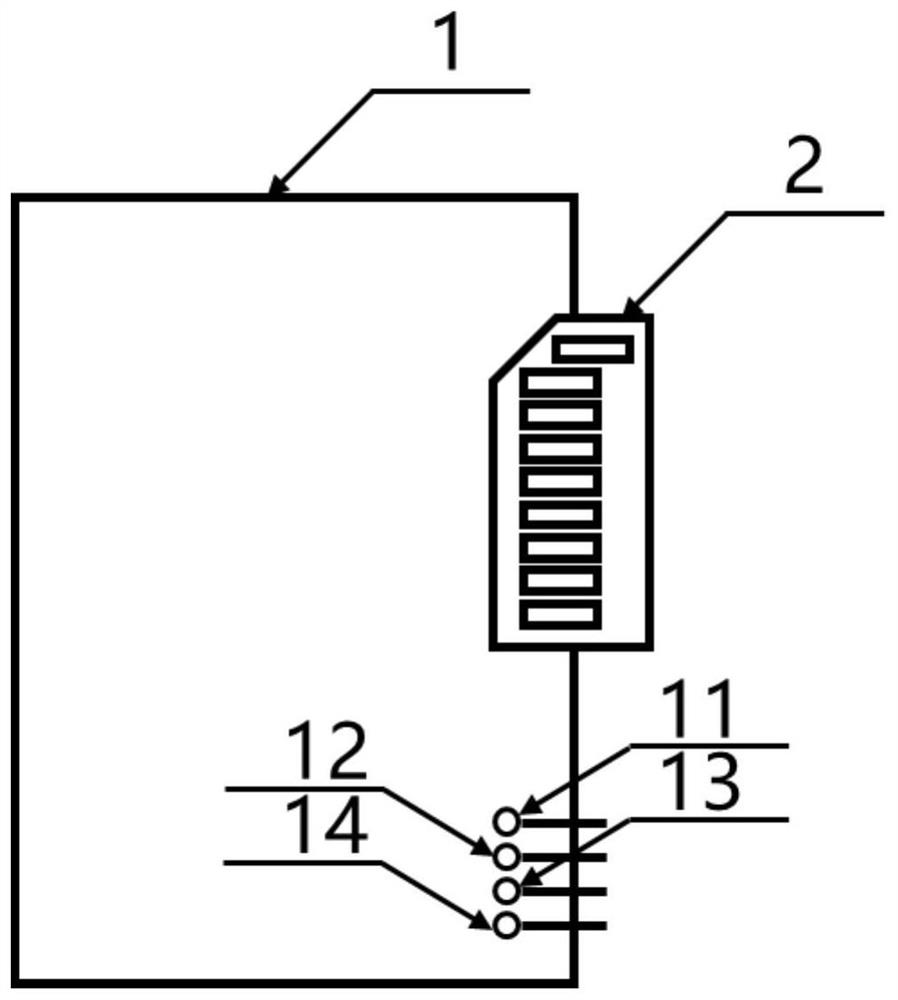

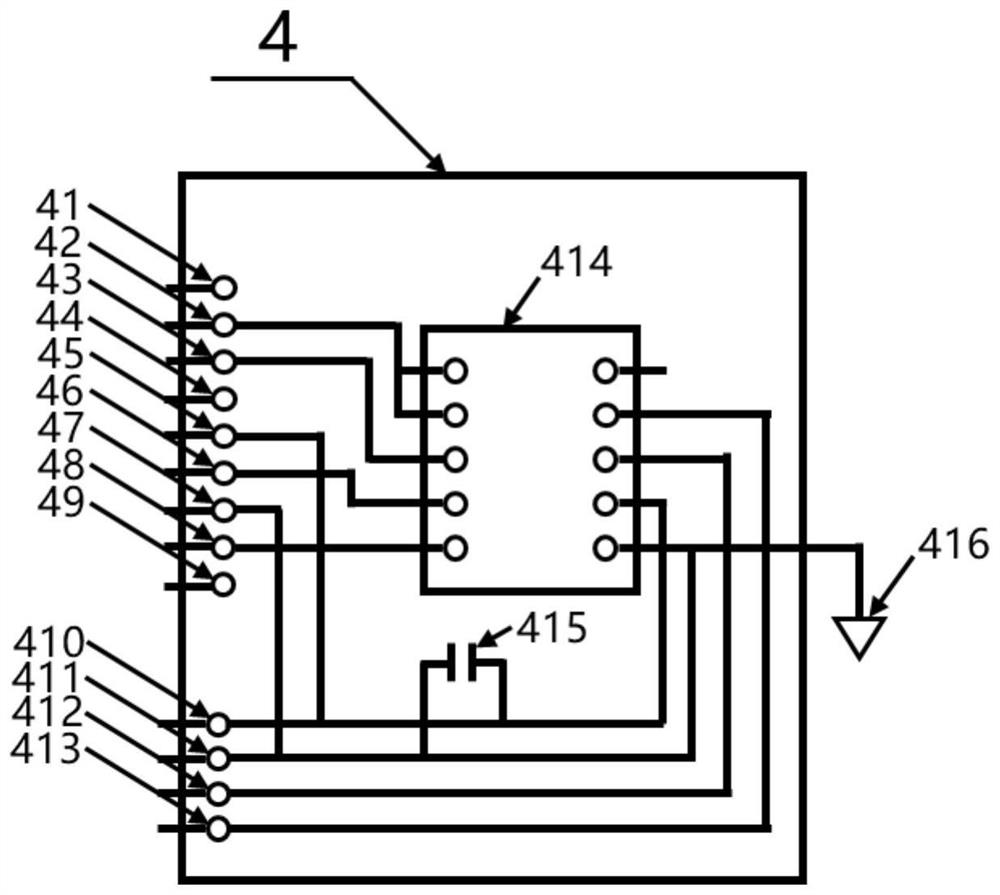

[0032] Example: see attached Figure 1-5 , the present invention provides a technical solution: a 3D printing wireless transmission control device for storage sharing and calling, which includes a 3D printing control board circuit 1, a memory interface 2, a data transmission line 3, a wireless transmission circuit 4, a memory 5, a control The command transmission line 6 and the resistor 7, wherein the 3D printing control board circuit 1 is a control circuit board for controlling the 3D printer to implement 3D printing forming operations, the memory 5 is a storage medium that can be used to store model files, and the wireless transmission circuit 4 is for realizing the model file The wireless transmission circuit of data and operation commands, the memory interface 2 is fixed on the 3D printing control board circuit 1, the memory interface 2 is set as the interface for data reading and writing between the 3D printing control board circuit 1 and the memory 5, and the 3D printing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com