A fuel cell microporous layer continuous printing equipment and process

A technology of fuel cell and printing equipment, which is applied in the field of continuous printing equipment and technology of fuel cell microporous layer, and can solve the problems that the screen printing technology cannot be applied more, the continuous production process cannot be achieved, and the production efficiency is affected. Achieve the effect of being conducive to overall transmission, saving fixed steps and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

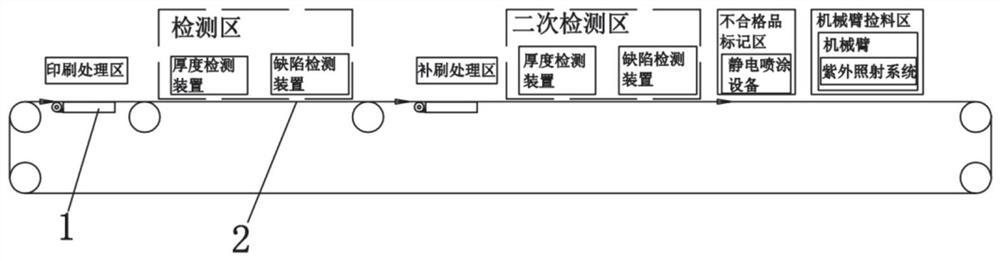

[0045] A kind of fuel cell microporous layer continuous printing equipment, such as figure 1 shown, including the following devices:

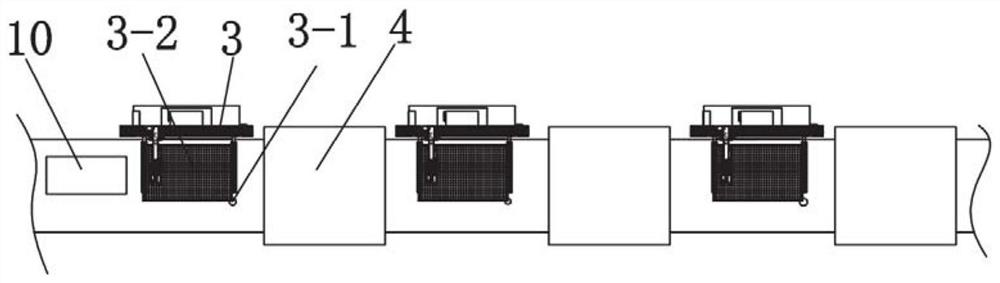

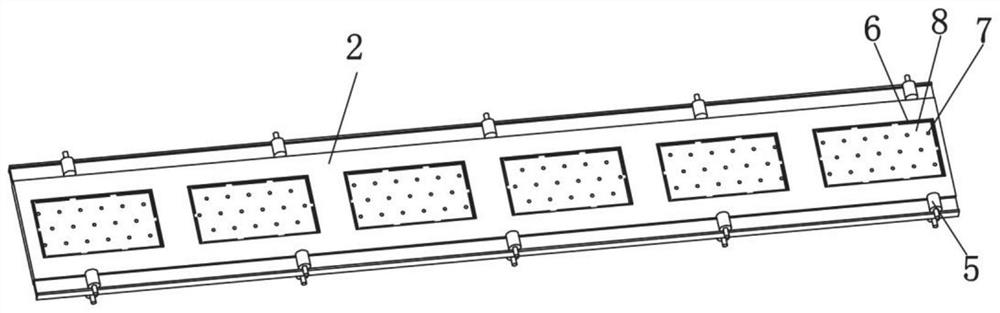

[0046] Conveyor belt assembly 2, the conveyer belt assembly 2 comprises the sheet base belt 2-1 that is wound on the roller wheel and forms loop, as figure 1 with 4 As shown, a plurality of metal support areas 2-2 are fixedly arranged in an array at intervals in the base band 2-1, and any metal support area 2-2 is formed by a plurality of thin strip-shaped metal sheets 2-2-1 arranged parallel to each other at intervals. Laying and fixing inside the film base belt 2-1 constitutes, the conveyor belt assembly 2 is driven by a servo motor to realize the transmission of the microporous layer, and the precise transmission control is performed by the servo controller in the servo motor. At the same time, the film base belt 2-1 is located above the metal support area 2-2 and is provided with a limit groove 8 for the microporous layer to be completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com