Self-stripping type heat shrinkage film and preparation process thereof

A heat-shrinkable film and self-peeling technology, applied in the types of packaged items, packaged food, packaging, etc., can solve problems such as affecting the normal use of electronic components, damage to electronic components, and difficulty in peeling, to improve convenience, reduce damage, The effect of reducing the difficulty of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

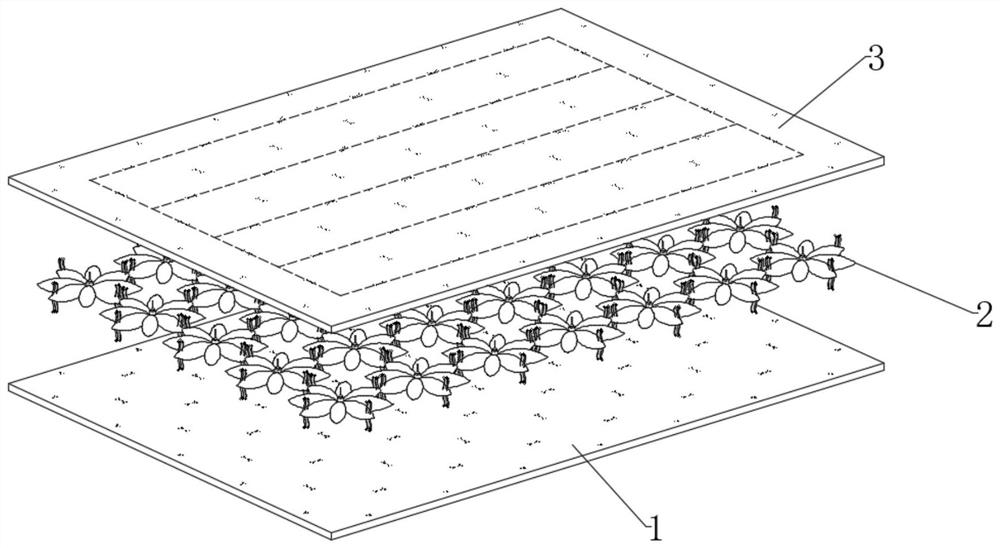

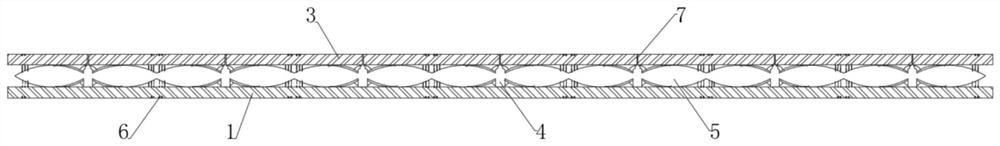

[0051] see Figure 1-10 , a self-peeling type heat shrinkable film, including a body, the body includes an antistatic base layer 1 on the lower side, a protective guiding friction layer 3 on the upper side, and an antistatic base layer 1 and the protective guiding friction layer 3. The flower-type shrinkage peeling layer 2, the flower-type shrinkage peeling layer 2 is respectively connected with the antistatic base layer 1 and the protective guiding friction layer 3, and a plurality of self-peeling anti-flowering films are arranged in the flower-type shrinkage peeling layer 2; please refer to figure 1 , the self-peeling anti-flower film includes a stamen conductive cylinder 4, and the outer end of the stamen conductive cylinder 4 is fixedly connected with a plurality of olive-shaped stripped petals 5 distributed in a circle, and the upper and lower ends of the olive-shaped stripped petals 5 are far away from the stamen conductive cylinder 4 One side is fixedly connected with a...

Embodiment 2

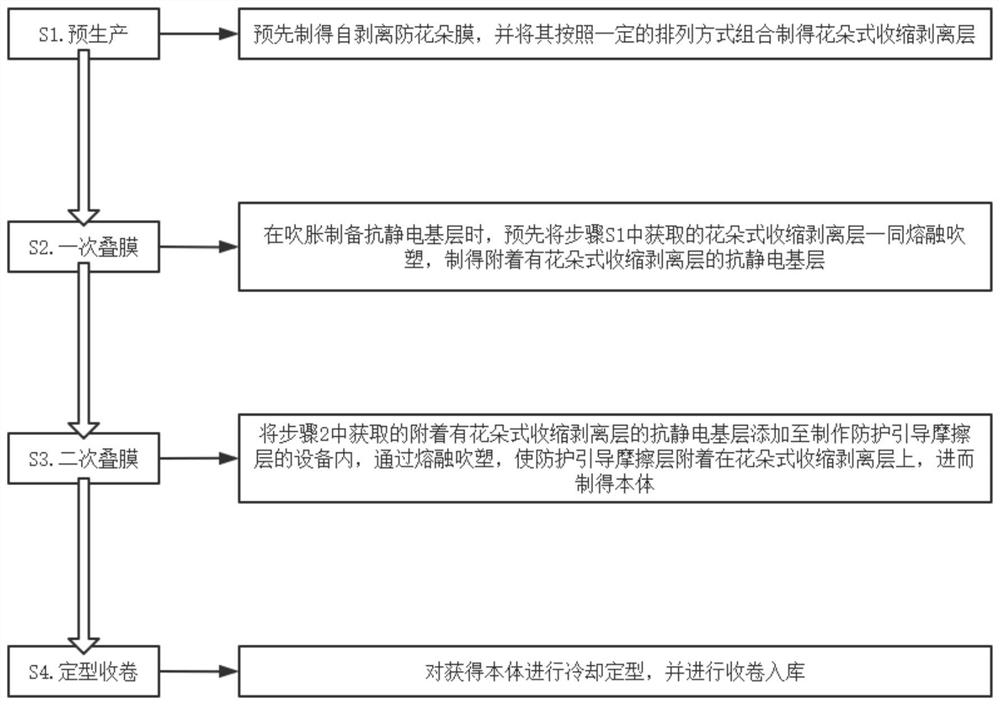

[0063] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 2 , a preparation process of a self-peeling type heat-shrinkable film, comprising the steps of:

[0064] S1. Pre-production: pre-prepared self-peeling anti-blossom film, and combined it according to a certain arrangement to make flower-shaped shrinkage peeling layer 2;

[0065]S2. Primary film lamination: when the antistatic base layer 1 is prepared by blowing, the flower-shaped shrinkable release layer 2 obtained in step S1 is melted and blown together in advance to obtain the antistatic base layer 1 attached with the flower-shaped shrinkable release layer 2;

[0066] S3. Secondary film lamination: add the antistatic base layer 1 obtained in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com