Axial fine adjustment and tensioning shaft

A technology of tensioning shaft and tensioning mandrel, applied in the field of axial fine-tuning tensioning shaft, which can solve problems such as high structural cost, inability to perform axial fine-tuning, and shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

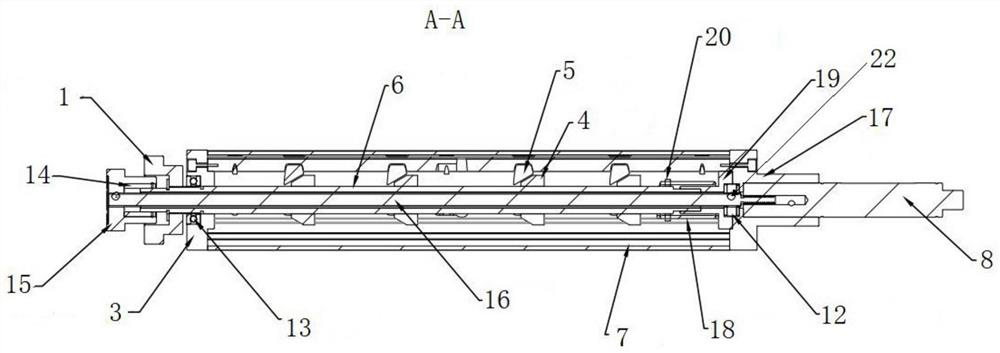

[0078] According to a specific embodiment of the present invention, the present invention will be described in detail with reference to the accompanying drawings.

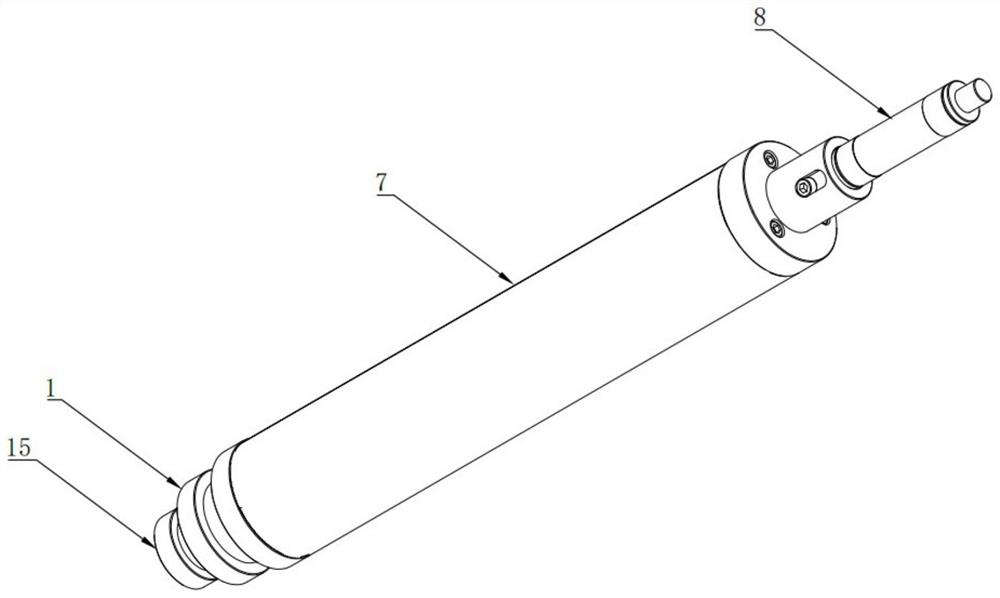

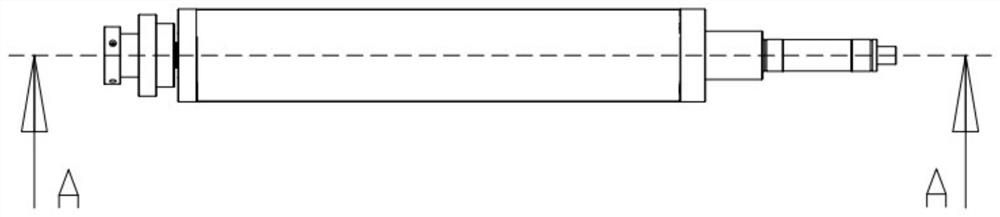

[0079] The present invention provides an axial fine-tuning tensioning shaft, which includes a tensioning assembly, an axial fine-tuning assembly and a motor transmission shaft 8;

[0080] The tensioning assembly includes a tensioning hand wheel 1, a tensioning mandrel 6, a guide cone sleeve 4, a telescopic cone sleeve 5, a loosening cylinder 7, a front support seat 3 of the tension mandrel and a rear support seat 17 of the tension mandrel;

[0081] The axial fine-tuning assembly includes an axial fine-tuning handwheel 15 and a fine-tuning mandrel 16;

[0082] The tensioning assembly is connected with the axial fine-tuning assembly; the fine-tuning assembly is connected with the motor transmission shaft 8;

[0083] One end of the loosening tube 7 is connected with the front support seat 3 of the tensioning mandrel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com