Jet compression type deep condensation dead steam heat pump circulation system

A deep condensing and circulating system technology, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of high energy consumption and operating costs, low heat pump performance coefficient and efficiency, and low heat pump evaporation temperature. The effect of reducing temperature, improving energy quality, and small loss of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

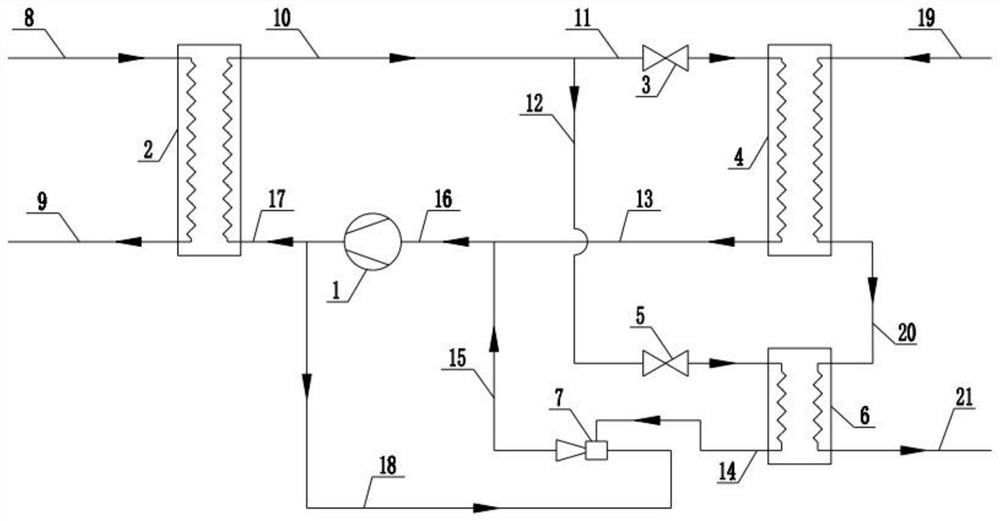

[0038] Detail embodiment 1: Combination figure 1 As shown, the present invention provides a heat pump circulating system of injection compression depth, including a first compressor, a heat pump condenser, a first throttle expansion valve, a heat pump first evaporator, a second throttle expansion valve. , Heat pump second evaporator, injector, first heat medium tube, second heat medium tube, first refrigerant line, second refrigerant line, third refrigerant line, fourth cooling Division pipeline, fifth refrigerant line, sixth refrigerant line, seventh refrigerant line, eighth refrigerant line, ninth refrigerant line, first lack of steam, second Pipeline, third lack of steam line,

[0039] The exit end of the first heat medium line is connected to the heat medium inlet end of the heat pump condenser, and the heat medium outlet end of the heat pump condenser is connected to the inlet end of the second heat medium line;

[0040] The inlet end of the first refrigerant pipe is connecte...

specific Embodiment approach 2

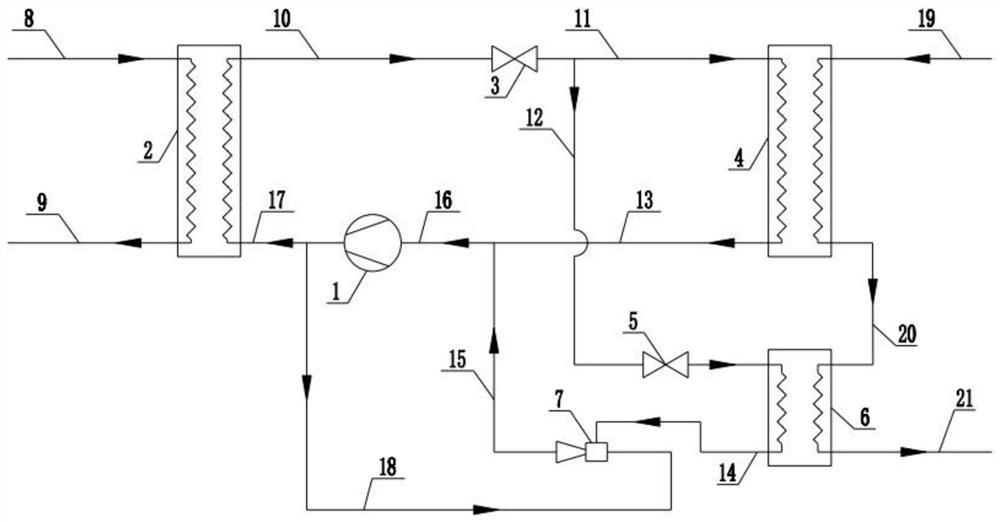

[0053] Detail Embodiment 2: Combination figure 2 As shown, a heat pump circulation system of injection compression depth, including a first compressor, a heat pump condenser, a first throttle expansion valve, a heat pump first evaporator, a second throttle expansion valve, and a heat pump second Evaporator, injector, first heat medium pipe, second heat medium pipe, first refrigerant line, second refrigerant line, third refrigerant line, fourth refrigerant line, Fifth refrigerant line, sixth refrigerant pipe, seventh refrigerant line, eighth refrigerant line, ninth refrigerant pipe, first lack of steam line, second lack of steam line, Three fasteners,

[0054] The exit end of the first heat medium line is connected to the heat medium inlet end of the heat pump condenser, and the heat medium outlet end of the heat pump condenser is connected to the inlet end of the second heat medium line;

[0055] The inlet end of the first refrigerant line is connected to the refrigerant outlet en...

specific Embodiment approach 3

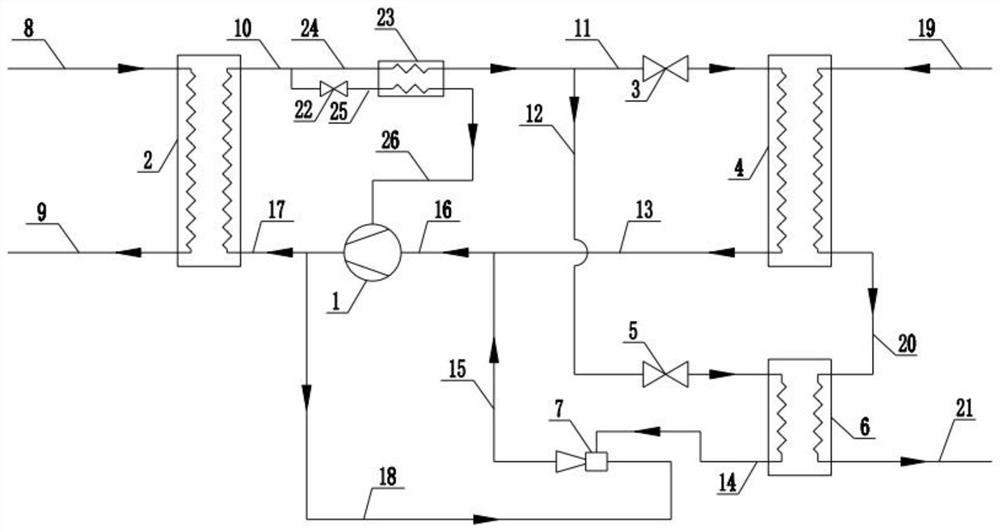

[0058] Specific implementation plan three: combined image 3 As shown, a heat pump circulation system of injection compression depth, including a first compressor, a heat pump condenser, a first throttle expansion valve, a heat pump first evaporator, a second throttle expansion valve, and a heat pump second Evaporator, injector, first heat medium pipe, second heat medium pipe, first refrigerant line, second refrigerant line, third refrigerant line, fourth refrigerant line, Fifth refrigerant line, sixth refrigerant pipe, seventh refrigerant line, eighth refrigerant line, ninth refrigerant pipe, first lack of steam line, second lack of steam line, Sanchai, third-stage flow expansion valve, economy, tenth refrigerant line, end, 11th refrigerant line, twelfth refrigerant pipeline,

[0059] The exit end of the first heat medium line is connected to the heat medium inlet end of the heat pump condenser, and the heat medium outlet end of the heat pump condenser is connected to the inlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com