Ship equipment fault diagnosis device based on off-line insulation monitoring and use method

A technology of equipment failure and diagnostic devices, which is applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as fire, problems, and major safety issues, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

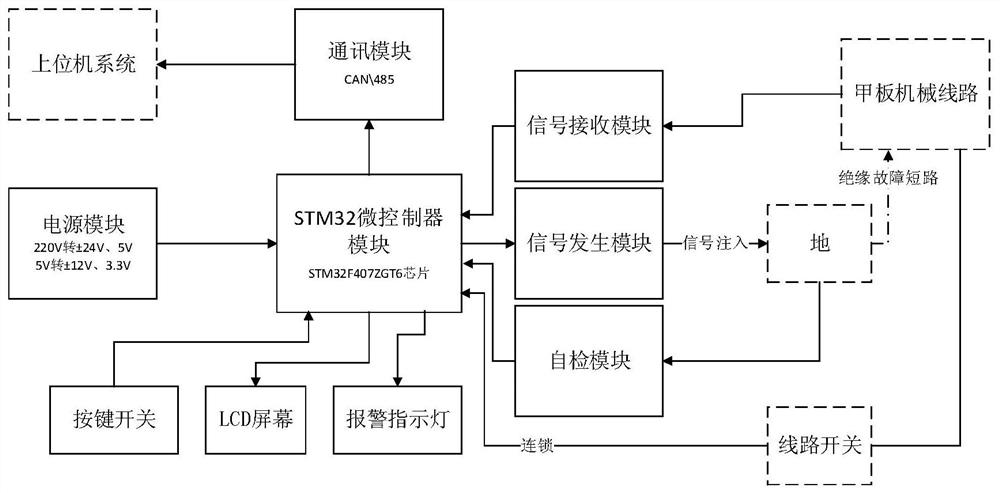

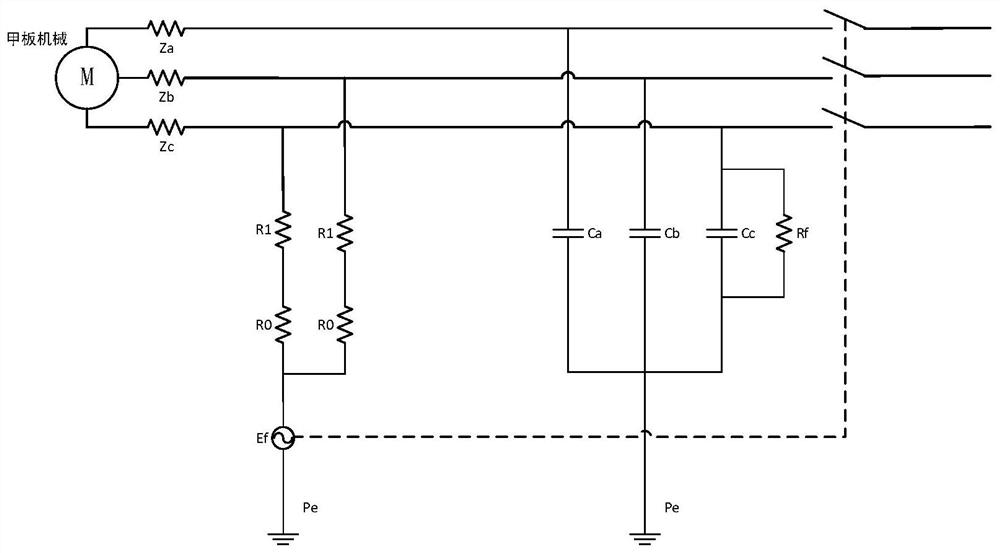

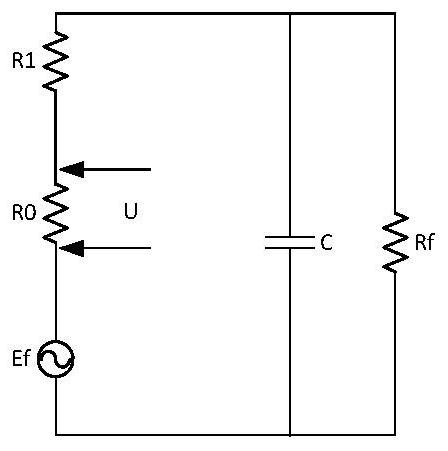

[0032] As shown in the figure, the ship equipment fault diagnosis device based on off-line insulation monitoring in this embodiment includes an STM32 microcontroller module, a signal generation module and a signal receiving module connected to the STM32 microcontroller module, and the signal generation module can continue to monitor A square wave signal is injected between the equipment line and the ground, and the signal receiving module can receive the signals connected to the monitoring equipment line and perform amplification and filtering processing. The STM32 microcontroller module is also connected to an alarm unit, and the STM32 microcontroller module controls the entire module system , can calculate and analyze the received signal to obtain the line resistance value. When the calculated insulation resistance value is less than the set value, the alarm information will be sent through the alarm unit. When the alarm unit is an alarm indicator light and LCD display, the al...

Embodiment 2

[0046] A method for using a ship equipment fault diagnosis device based on off-line insulation monitoring, comprising the following steps:

[0047] A. The power supply module supplies power to the entire ship equipment fault diagnosis device. The ship equipment fault diagnosis device detects the closed state of the grid line switch. When the grid line switch disconnects the grid and enters the offline state, the offline monitoring starts to run. When the grid line switch is closed, Exit offline monitoring;

[0048] B. When offline monitoring is running, the signal generation module continuously injects low-frequency square wave signals between any two phases of the monitored equipment line and the ground;

[0049] C. The self-inspection module is grounded and continuously monitors the operating status of the ship's equipment fault diagnosis device;

[0050] D. The signal receiving module receives the signals of the two items of the line, and transmits the collected signals to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com