Gearbox gear fault diagnosis method

A fault diagnosis and gearbox technology, applied in neural learning methods, biological neural network models, testing of mechanical components, etc., can solve problems such as difficult fault diagnosis of gearbox gears, avoid sudden accidents, improve accuracy and Fairness, the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

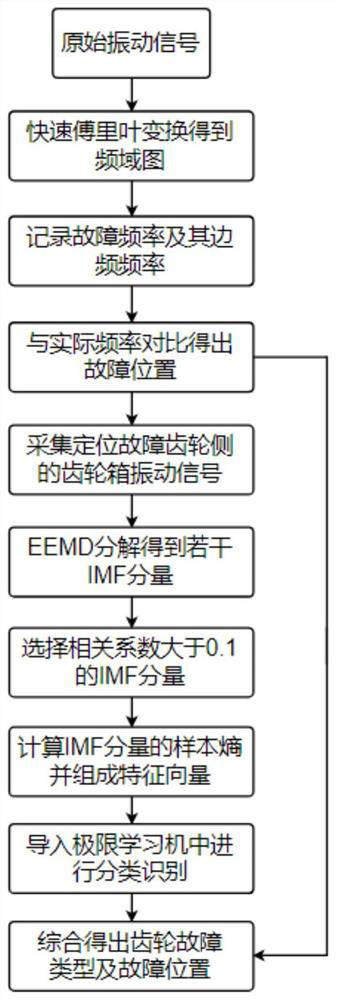

[0051] The gearbox gear fault diagnosis method is based on the vibration signal generated during the operation of the gearbox. During the operation of the gearbox, no matter whether there is a gear fault, the vibration signal will be generated, but the vibration signal when there is a gear fault is different from that without gear fault. There is a difference in the vibration signal at the time. When the gearbox gear is not faulty, the main vibration signals during operation are the meshing frequency of the gear and the rotation frequency of the gear. When there is a fault in the gear, the vibration signal will change due to the impact effect of the faulty gear during operation. At this time, the vibration signal contains the meshing frequency, rotation frequency and rotation frequency of the faulty gear at the same time.

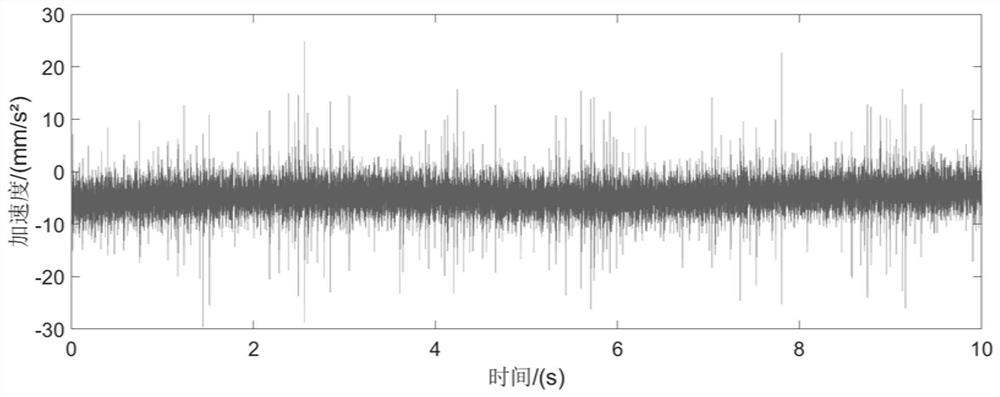

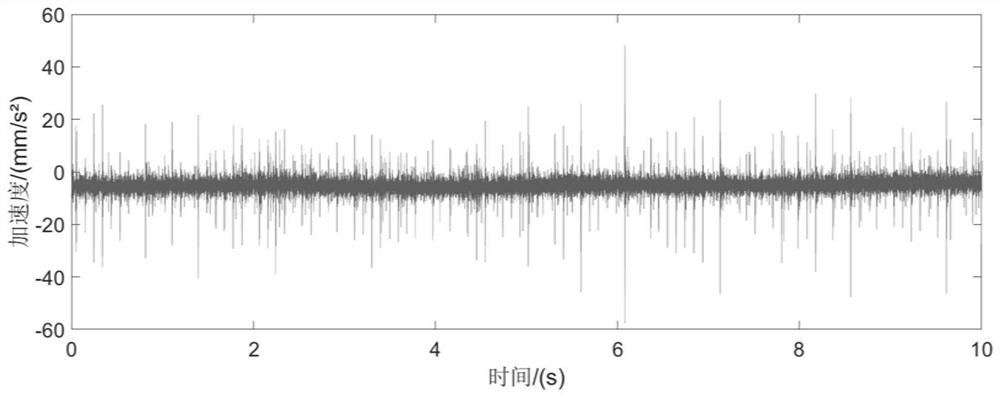

[0052] The test data used in this patent comes from the Jiangsu Qianpeng QPZZ-Ⅱ rotating machinery vibration analysis and fault diagnosis test platform sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com