Rotating spacer anti-galloping efficiency evaluation method

A performance evaluation and spacer technology, which is applied in the field of power transmission, can solve the problems of no anti-flight performance evaluation mechanism, lack of research on anti-flight performance and configuration schemes, and short application time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

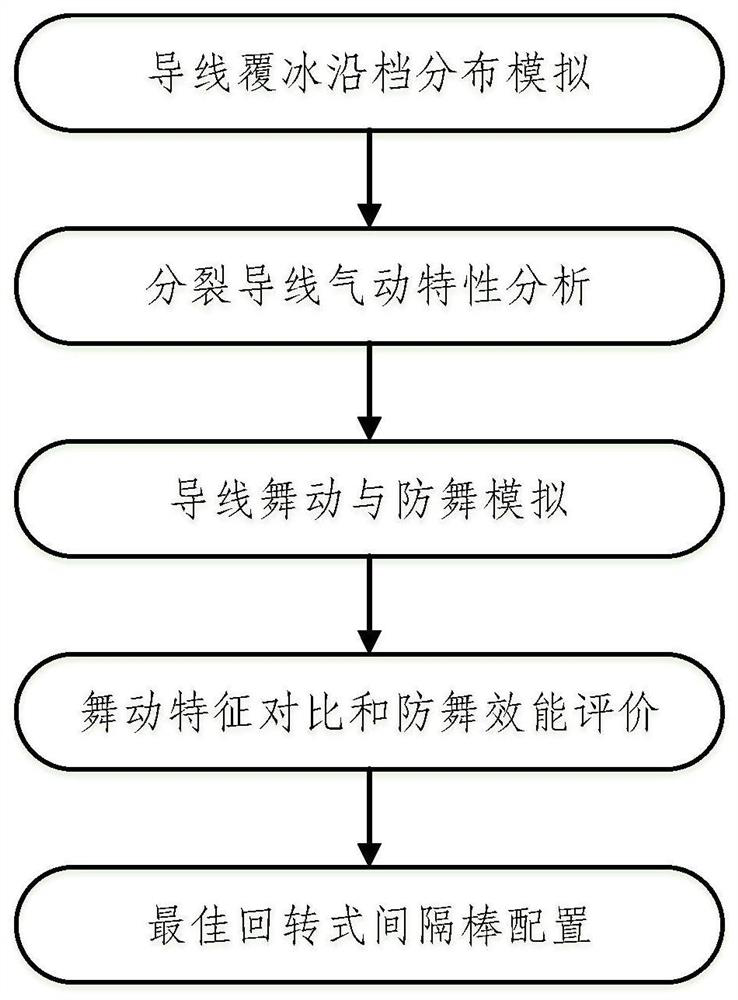

[0078] like figure 1 As shown, the present invention provides a method for evaluating the anti-dancing performance of a rotary spacer, comprising the following steps:

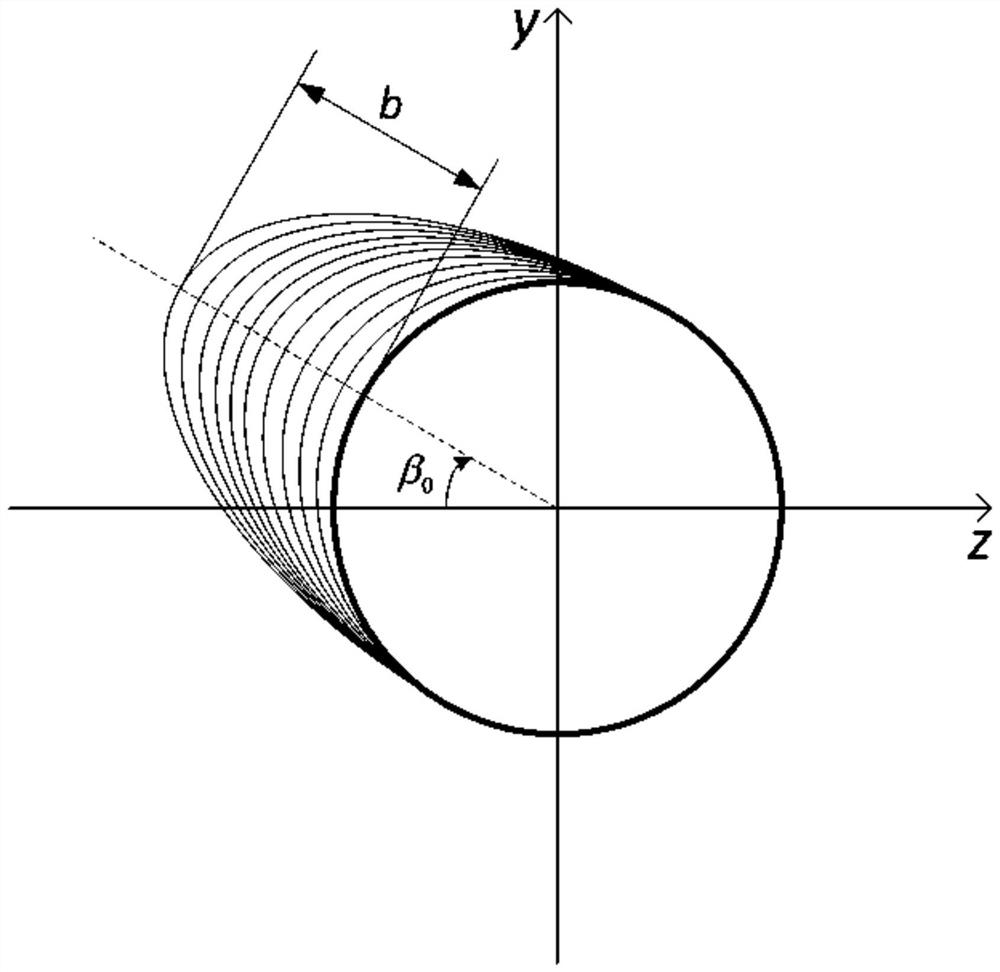

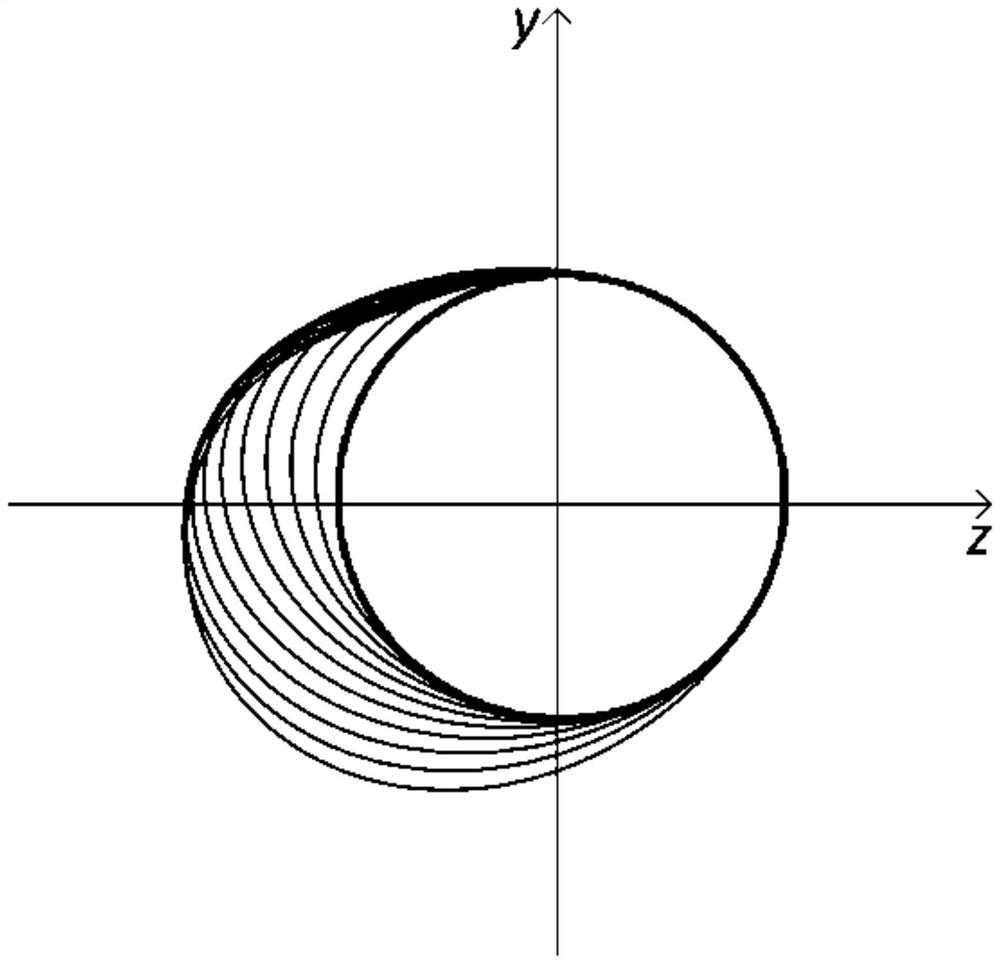

[0079] Step 1, Conductor icing distribution simulation along the shelf. Numerical method is used to simulate the change of ice-covered shape along the shelf on the non-torsion-constrained sub-conductor, and the ice-covered section of the conductor along the shelf is obtained.

[0080] For wires with low torsional stiffness and no torsional constraints, the wires can rotate continuously under the action of eccentric ice coating during dynamic icing. In order to obtain the final ice-coated shape on the cross-section, it is assumed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com