Vacuum low-temperature belt dryer

A vacuum drying and drying machine technology, applied in the direction of separation methods, chemical instruments and methods, evaporator accessories, etc., can solve the problems of affecting the drying efficiency and reducing the conveying speed of the conveyor belt, so as to ensure the drying effect, improve the uniformity, and improve the drying efficiency. The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

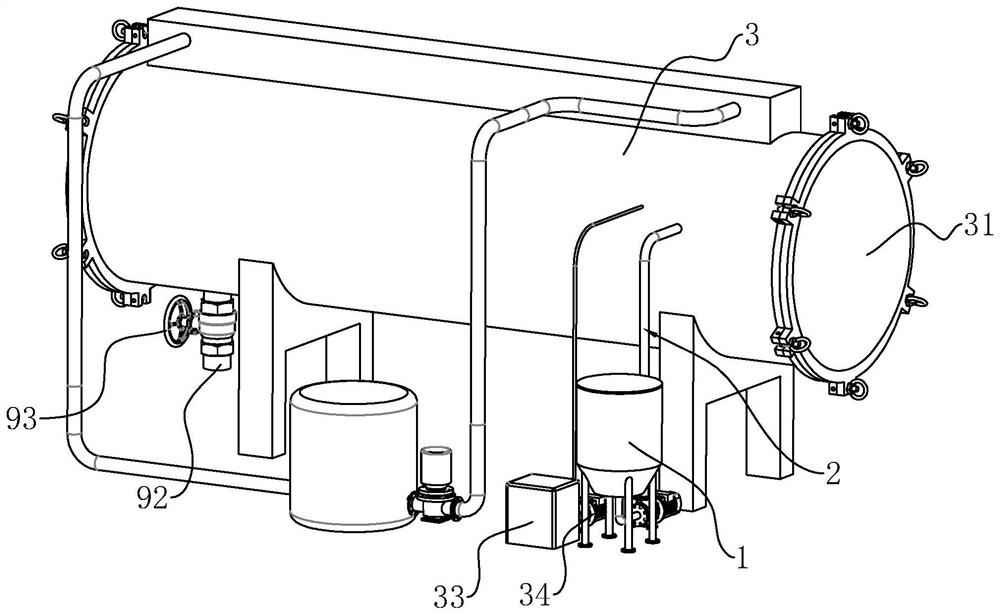

[0039] The embodiment of the present application discloses a vacuum low temperature belt dryer, refer to figure 1 , including a raw material mixing tank 1, a distributing device 2 and a vacuum drying tank body 3, and the raw material mixing tank 1 is located on one side of the vacuum drying tank body 3.

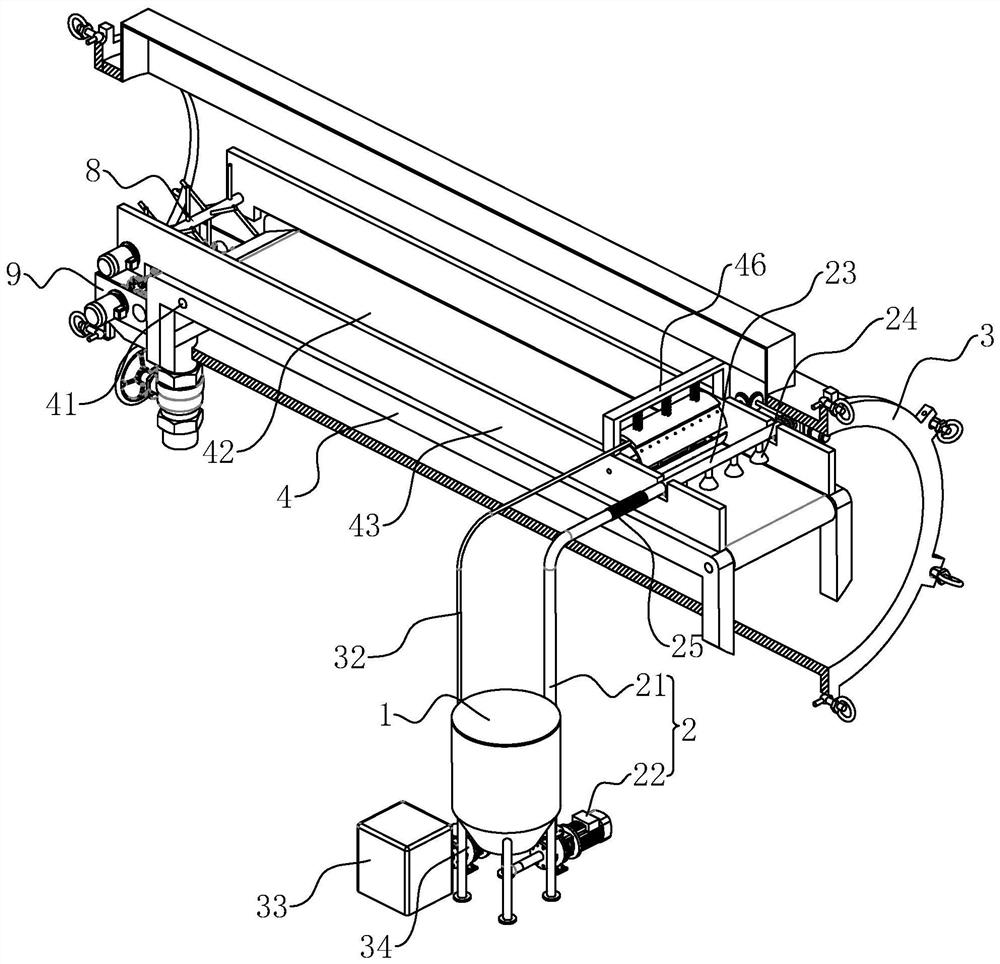

[0040] refer to figure 2 The two ends of the vacuum drying tank body 3 are openings, and the two ends of the vacuum drying tank body 3 are hinged with an end cover 31 to control the opening and closing of the opening. The vacuum drying tank body 3 is fixedly connected with a conveyor frame 4, and the conveyor Both ends of the frame 4 are rotatably connected with conveying rollers 41 , and the conveying frame 4 is provided with a conveying belt 42 wound around the conveying rollers 41 to convey materials.

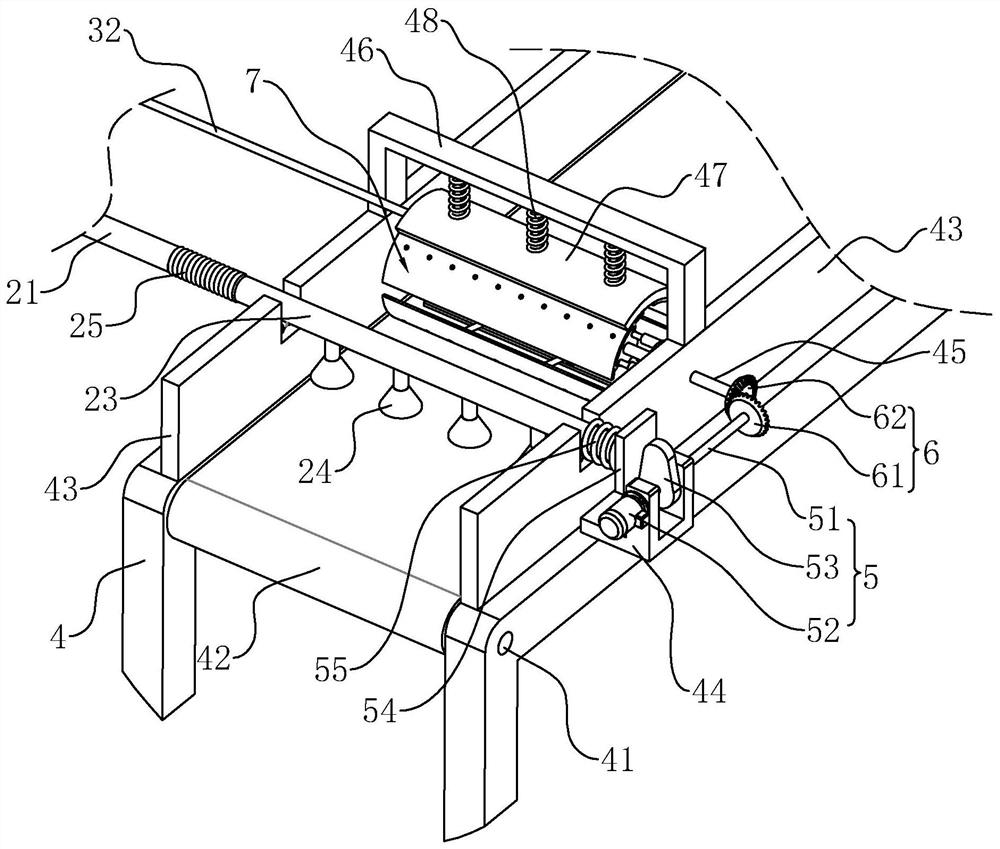

[0041] refer to image 3 , the conveyor frame 4 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com