Sample grinding box cleaning device and cleaning method thereof

A technology for cleaning device and grinding sample box, which is applied to cleaning methods and utensils, cleaning methods using liquids, cleaning hollow objects, etc., can solve the problems of time-consuming and laborious cleaning process, unfavorable development of automatic integration of sample preparation and sample grinding equipment, etc. To achieve the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

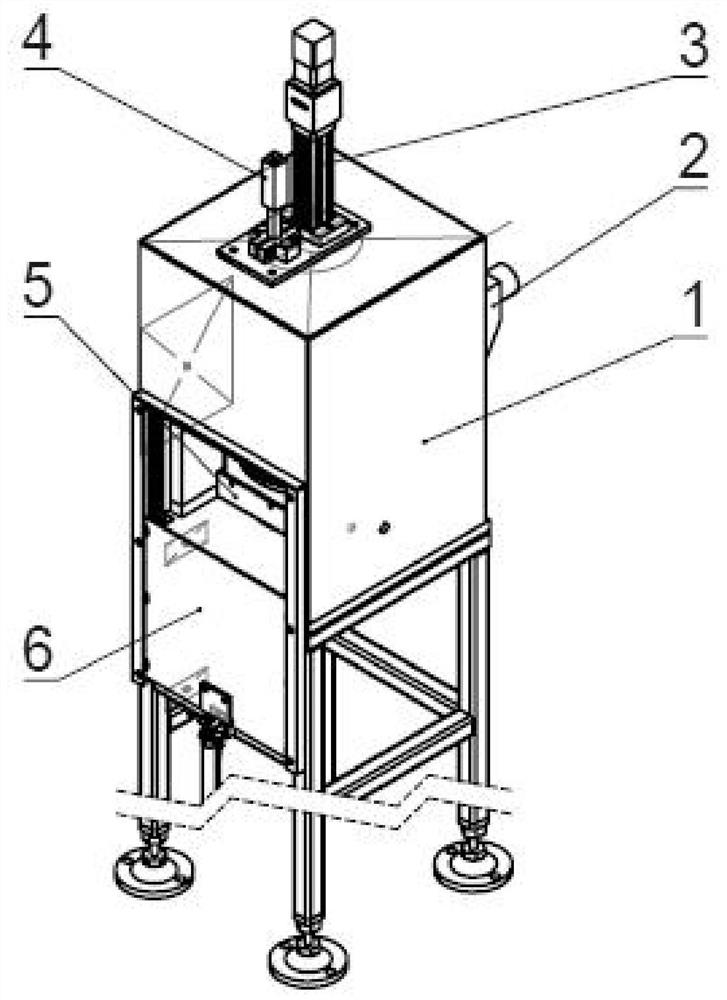

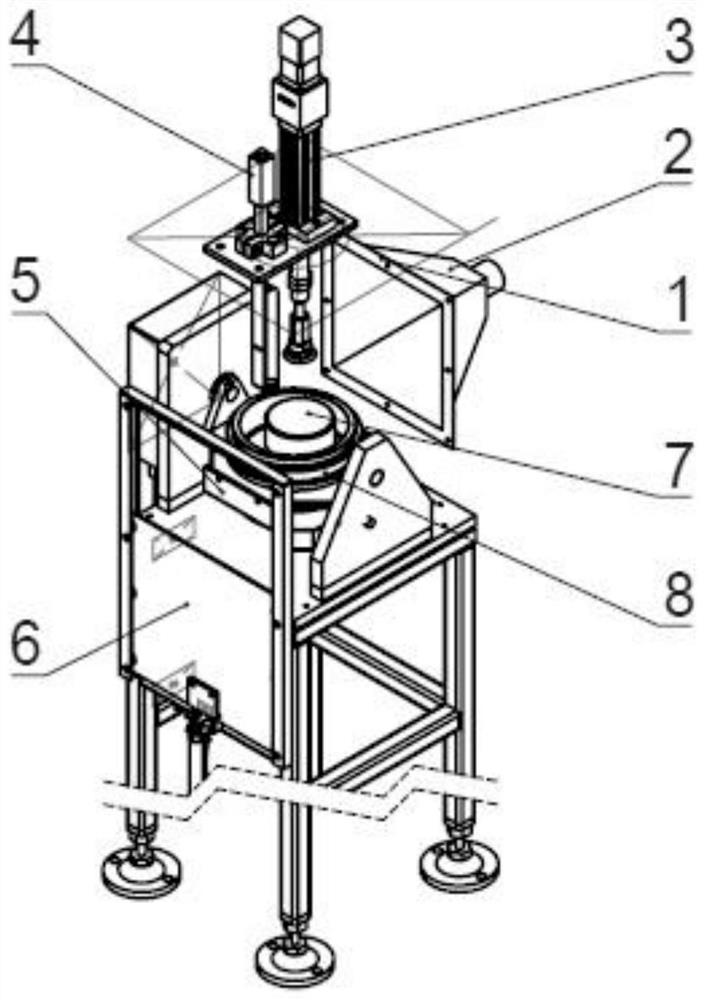

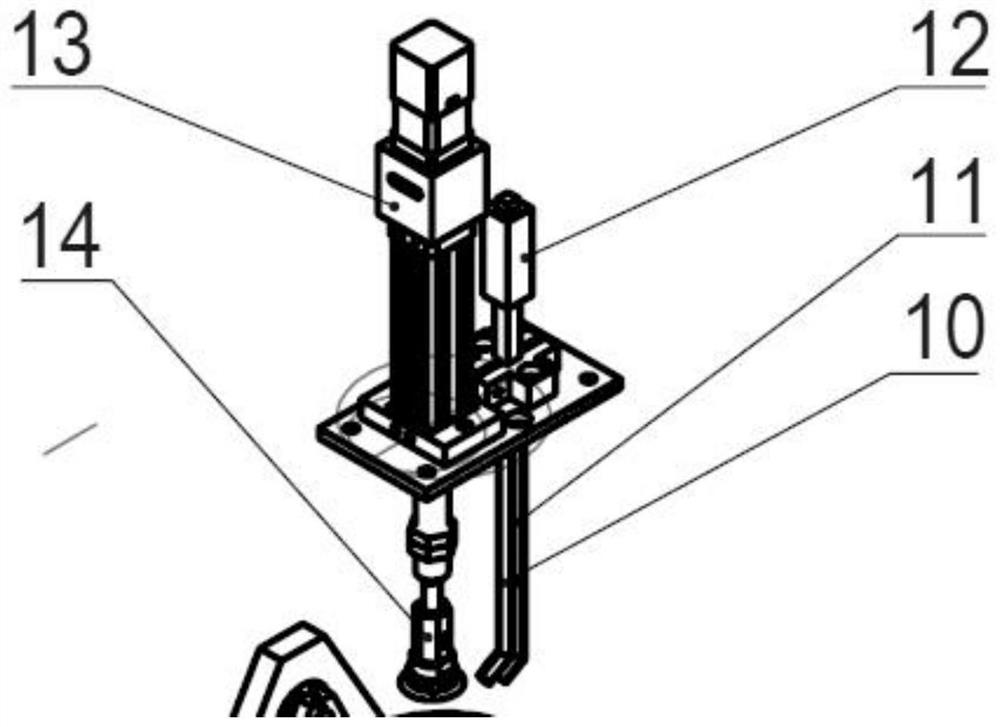

[0025] Embodiments of the present invention: at first, on the whole, the present invention comprises cleaning cabin, overturning device 5, sucker device 3, air blowing device 4 and dust suction device, by Figure 1-2 The external configuration and internal detailed structure of the present invention can be understood separately. In addition, it can be seen that the dust collection device mainly includes a dust collection cover 2 and an external high-power vacuum cleaner. The vacuum cleaner is a mature product and will not be repeated here. The cleaning cabin includes a cabin body 1, a hatch door 6 and a hatch door driving electric cylinder 9. The cabin body 1 is a box body closed on five sides, and forms a closed box body structure with the hatch door 6, which serves as a vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com