Forging and pressing equipment for machining automobile parts

A technology of auto parts and forging equipment, which is applied in the field of auto parts processing, can solve the problems that affect the processing quality of parts, humidity, and the cooling effect of water spray is not obvious, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

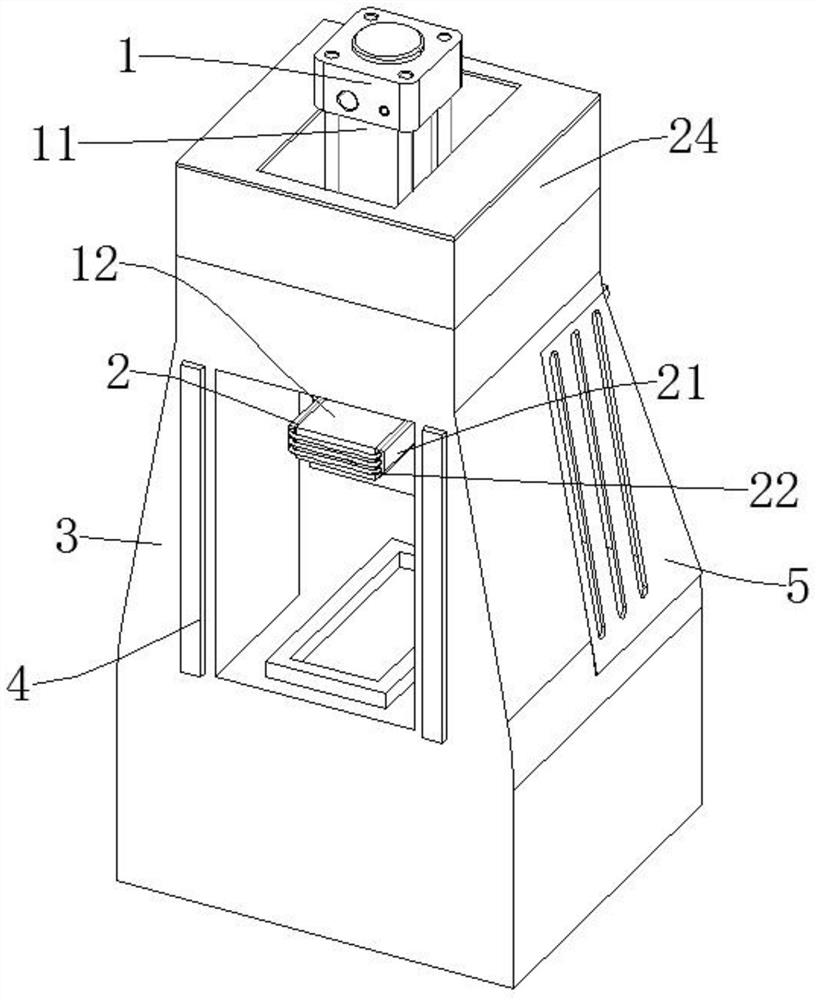

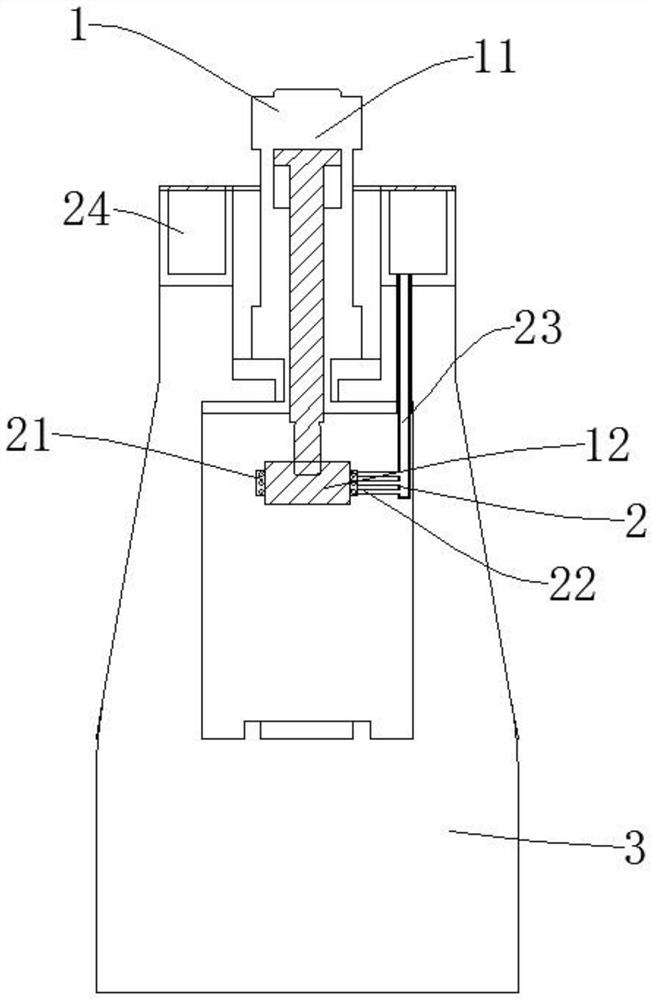

[0029] Such as figure 1 , image 3 , Figure 5 , Figure 6 As shown, the forging mechanism 1 includes a hydraulic cylinder 11 and a forging hammer 12. The fixed part of the hydraulic cylinder 11 is connected to the top of the machine base 3 by bolts. The forging hammer 12 moves downward, and the auto parts are forged and processed by the forging hammer 12 moving downward; the cooling mechanism 2 includes a cooling seat 21, a cooling tube 22, a lifting tube 23, and a cooling box 24, and the cooling seat 21 is connected by screws. On both sides of the forging hammer 12, the cooling pipe 22 is connected to the front and rear ends of the two cooling seats 21 by welding. The cooling water in 24 enters in the cooling pipe 22 through the lifting pipe 23, utilizes the cooling pipe 22 to import the cooling water into the cooling seat 21, and utilizes the cooling seat 21 to absorb the heat of the forging hammer 12.

[0030] Working principle: before use, add an appropriate amount of...

Embodiment 2

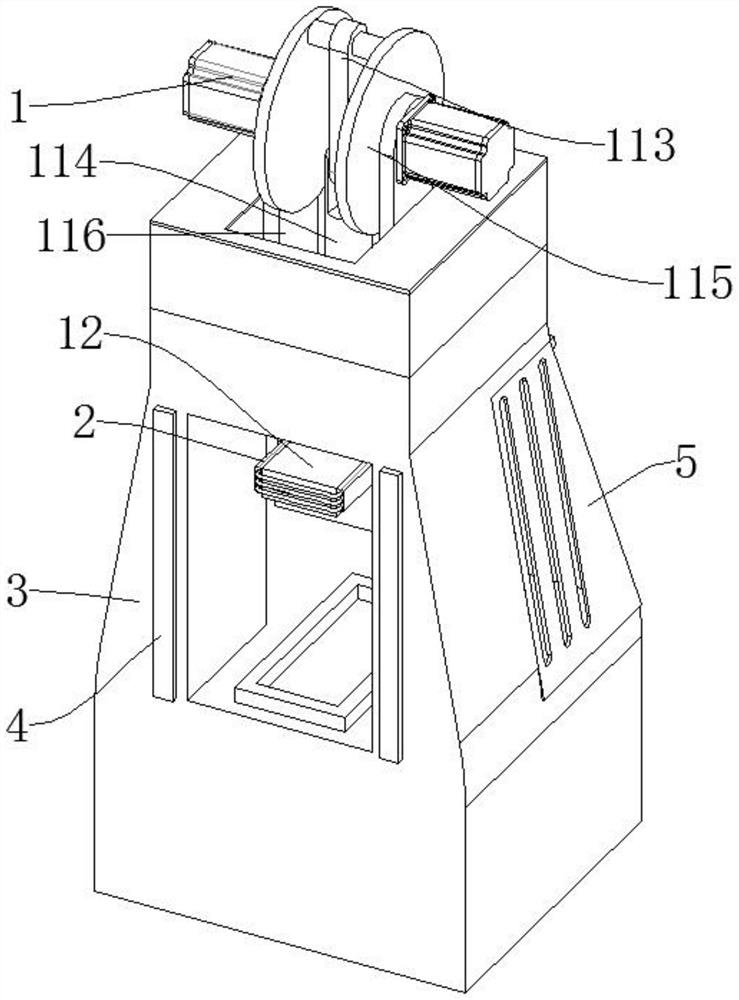

[0032] Such as figure 2 , Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the forging mechanism 1 includes a forging motor 111, a forging hammer 12, a pull rod 113, a connecting rod 114, a cam 115, and a fixed frame 116, and the lower end of the fixed frame 116 is connected to the base by welding. 3 At the top, the forging motor 111 is connected to the fixed frame 116 through bolts, the cam 115 is connected to both sides of the fixed frame 116 through bearings, the upper end of the pull rod 113 is connected to the cam 115 through a bearing, and the lower end of the pull rod 113 is connected to the upper end of the connecting rod 114 through a bearing. The lower end of the connecting rod 114 is screwed to the forging hammer 12, and the rotating part of the forging motor 111 is used to drive the cam 115 to rotate. The rotation of the cam 115 drives the pull rod 113 and the connecting rod 114 to move upward, and the up and down movement of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com