Negative pressure type self-mixing double-agent packaging bottle

A self-mixing, negative pressure technology, applied in packaging, transportation and packaging, containers with multiple items, etc., can solve the problems of high-viscosity materials that are not easy to mix, easy to spray liquid, etc., to extend the shelf life and Long service life, avoid extrusion and splashing, good-looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

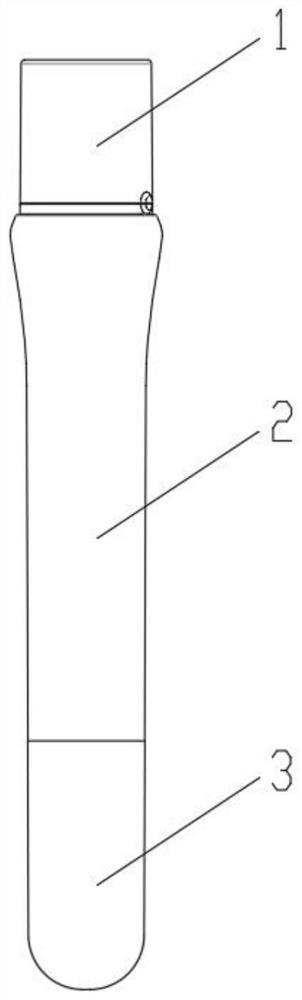

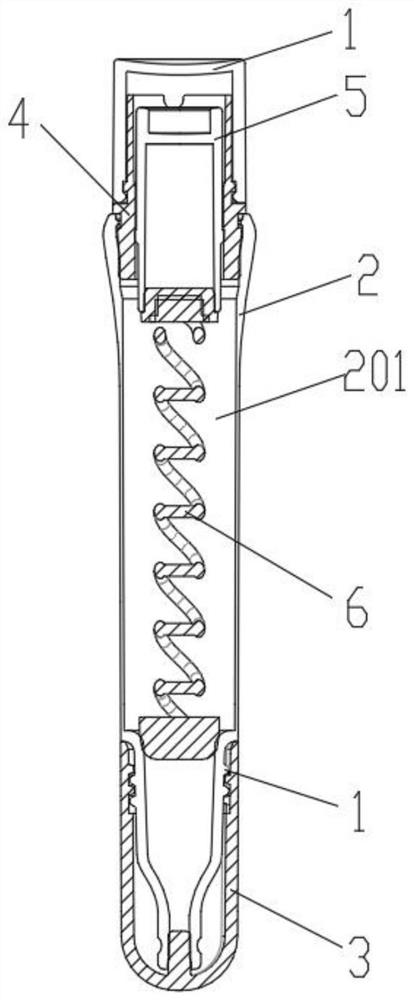

[0028] A negative-pressure self-mixing double-dose packaging bottle, comprising a bottle body 2, a top cap 1 is provided on the top of the bottle body 2, and a bottom cap 3 is provided on the bottom; Connector 4; inside the connector 4 there is also a small silo 5; the bottom of the connector 4 is also connected with a stirring rod 6; the small silo 5 can move up and down relative to the connector 4 driven by the rotation of the top cap 1 .

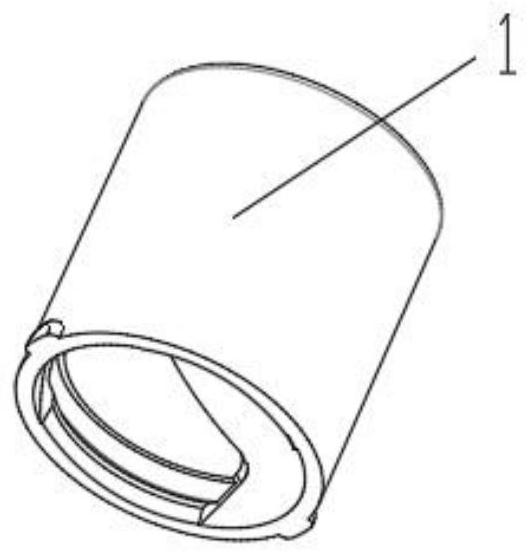

[0029] The inner wall of the top cap 1 is provided with a groove 101; the outer wall of the small hopper 5 is symmetrically provided with lug posts 501; the lug posts 501 are stuck in the groove 101, thereby realizing a pair of small material The driving effect of warehouse 5.

[0030] The inside of the bottle body 2 is a through bottle cavity 201, and the stirring rod 6 is arranged in the bottle cavity 201; the bottom outer wall of the bottle body 2 is also provided with an external thread 202 of the bottle.

[0031] The bottom center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com