Two-stage homogenization treatment process for H13 die steel

A homogenization treatment and two-stage homogenization technology, applied in the field of materials, can solve the problems of coarse grains and high process costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A two-stage homogenization treatment process for H13 die steel, the specific operation steps include:

[0022] (1) H13 hot work die steel is prepared by a certain smelting method, the composition is (mass percentage): C 0.41%, Si 1.11%, Mn 0.45%, Cr 5.45%, Mo 1.74%, V 1.15%, unavoidable impurities Content <0.1%, the balance is Fe;

[0023] (2) Put the mold steel into the soaking furnace, firstly perform the first-level homogenization treatment of the cast ingot at 800°C / 3h, and water-cool to room temperature after the heat preservation is completed;

[0024] (3) Place the mold steel after primary homogenization treatment in a soaking furnace, perform secondary homogenization treatment at 1200°C / 1h, and water cool to room temperature after heat preservation.

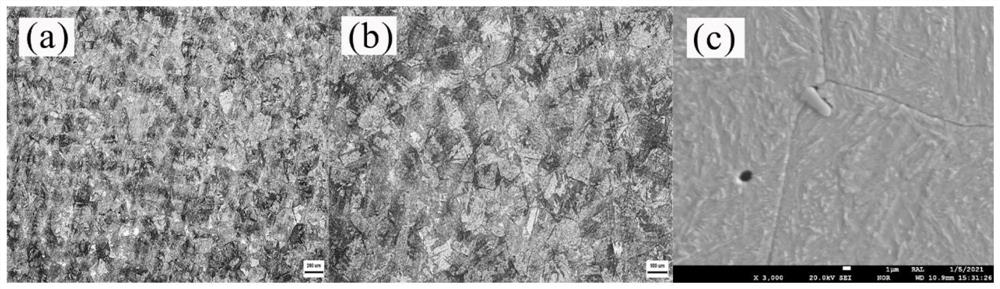

[0025] The microstructure of the H13 die steel sample after two-stage homogenization treatment is as follows: figure 1 shown. figure 1 (a) shows the dendrite segregation morphology. It can be seen that the dendr...

Embodiment 2

[0027] A two-stage homogenization treatment process for H13 die steel, the specific operation steps include:

[0028] (1) H13 hot work die steel is prepared by a certain smelting method, the composition is (mass percentage): C 0.37%, Si 1.01%, Mn 0.35%, Cr 5.15%, Mo 1.47%, V 1.01%, unavoidable impurities Content <0.1%, the balance is Fe;

[0029] (2) Put the die steel into the soaking furnace, and firstly perform the first-level homogenization treatment of the cast ingot at 800°C / 2h, and then water-cool to room temperature after the heat preservation is completed;

[0030] (3) Place the mold steel after primary homogenization treatment in a soaking furnace, perform secondary homogenization treatment at 1200°C / 2h, and water cool to room temperature after heat preservation.

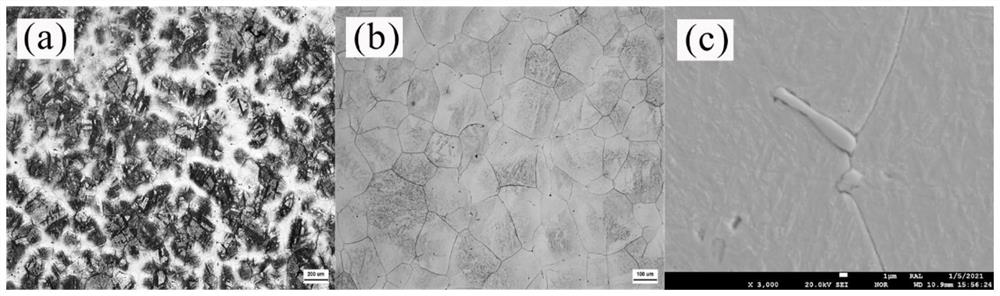

[0031] The microstructure of the H13 die steel sample after two-stage homogenization treatment is as follows: figure 2 shown. figure 2 (a) shows the dendrite segregation morphology. It can be seen that...

Embodiment 3

[0033] A two-stage homogenization treatment process for H13 die steel, the specific operation steps include:

[0034] (1) H13 hot work die steel is prepared by a certain smelting method, the composition is (mass percentage): C 0.33%, Si0.89%, Mn 0.26%, Cr 4.82%, Mo 1.28%, V 0.83%, unavoidable impurities Content <0.1%, the balance is Fe;

[0035] (2) Put the die steel into the soaking furnace, firstly perform the first-level homogenization treatment of the cast ingot at 800°C / 1h, and water-cool to room temperature after the heat preservation is completed;

[0036] (3) Place the mold steel after primary homogenization treatment in a soaking furnace, perform secondary homogenization treatment at 1200°C / 3h, and water cool to room temperature after heat preservation.

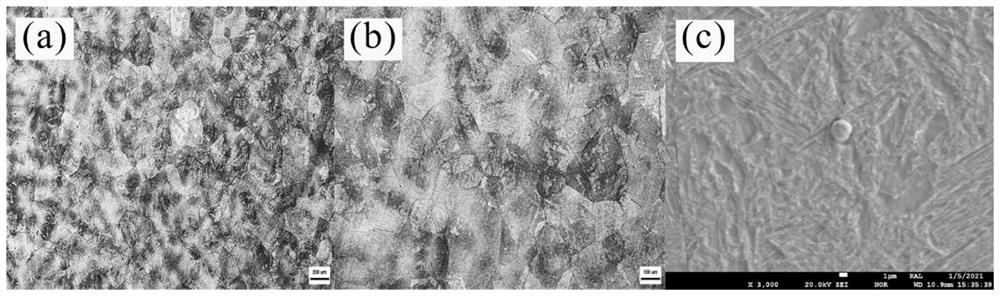

[0037] The microstructure of the H13 die steel sample after two-stage homogenization treatment is as follows: image 3 shown. image 3 (a) shows the dendrite segregation morphology. It can be seen that the dendrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com