Self-locking air cylinder

A cylinder, self-locking technology, applied in the direction of fluid pressure actuating devices, can solve problems such as locking, and achieve the effects of scientific design, strong practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

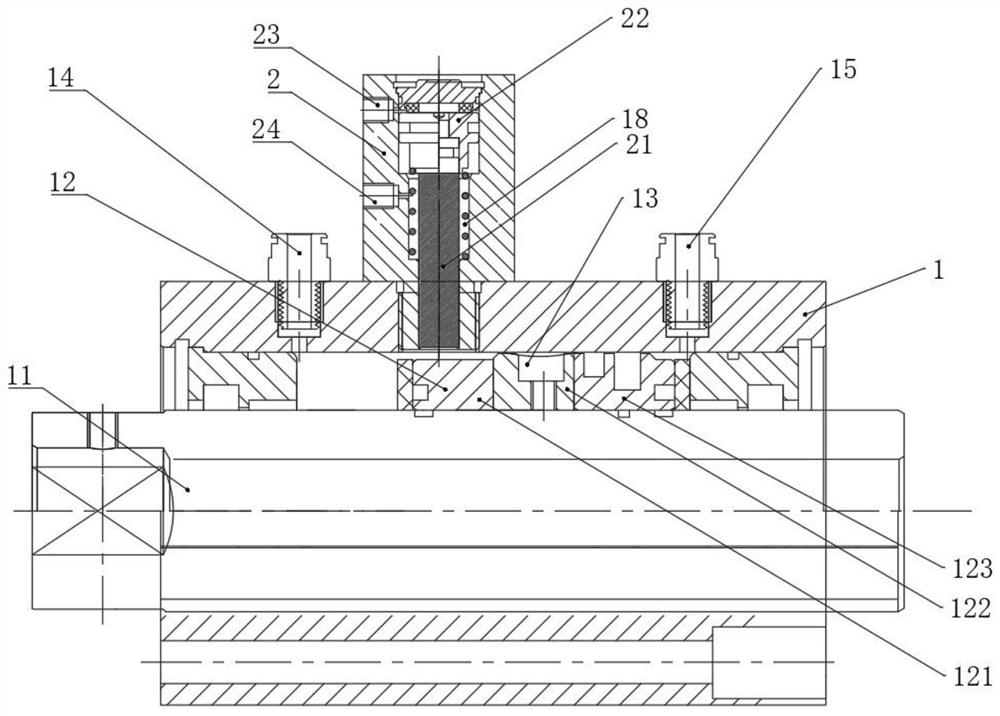

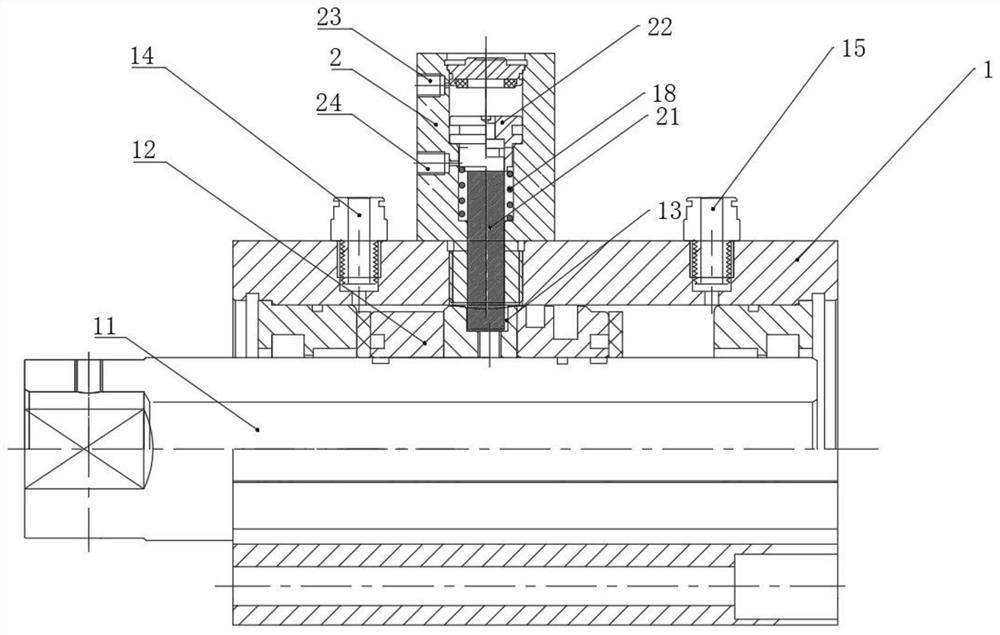

[0034] Example 1: The working principle of this solution product used on the button sewing machine

[0035] The working process of the traditional button sewing machine is generally produced by upper and lower double cylinders. The pressure of the upper cylinder is generally greater than that of the lower cylinder, and the lower cylinder also needs to lower the button based on the telescopic load, so that the upper and lower buttons can be pressed together. Before that, the radial setting The scheme of the auxiliary cylinder often has the problem of not locking up and down in time, resulting in incomplete upper and lower pressing, and not timely unlocking, resulting in jamming or equipment damage. However, the self-locking cylinder of this scheme has a simple structure and ingenious design. The main cylinder 1 is also equipped with an auxiliary cylinder 2. , the difference is that the auxiliary cylinder 2 of this program is provided with double air intake holes and a damping sp...

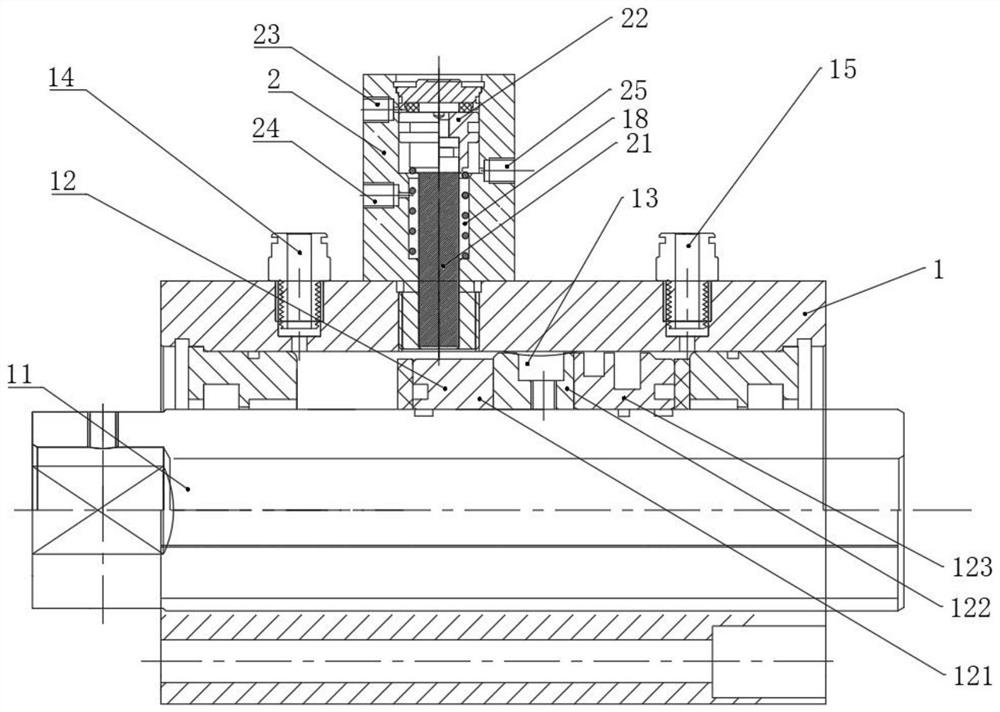

Embodiment 2

[0039] The working process of the traditional button sewing machine is generally produced by upper and lower double cylinders. The pressure of the upper cylinder is generally greater than that of the lower cylinder, and the lower cylinder also needs to lower the button based on the telescopic load, so that the upper and lower buttons can be pressed together. Before that, the radial setting The scheme of the auxiliary cylinder often has the problem of not locking up and down in time, resulting in incomplete upper and lower pressing, and not timely unlocking, resulting in jamming or equipment damage. However, the self-locking cylinder of this scheme has a simple structure and ingenious design. The main cylinder 1 is also equipped with an auxiliary cylinder 2. , the difference is that the auxiliary cylinder 2 of this program is provided with three air inlets and is provided with a damping spring 18 and has a set of ingenious gas circuit connection. If the air pump is used to suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com