Water conveying pipeline

A technology for water delivery pipes and pipe bodies, which is applied in the direction of pipes, rigid pipes, and general water supply saving, etc. It can solve the problems of heavy weight of concrete pipes, difficulties in transportation and installation, and low tensile strength, so as to save material costs and superior crack resistance The effect of superiority and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

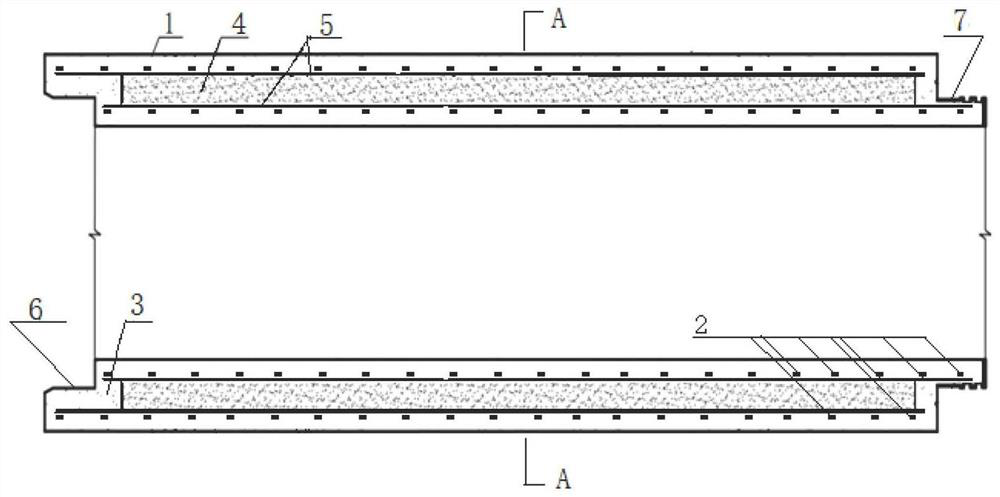

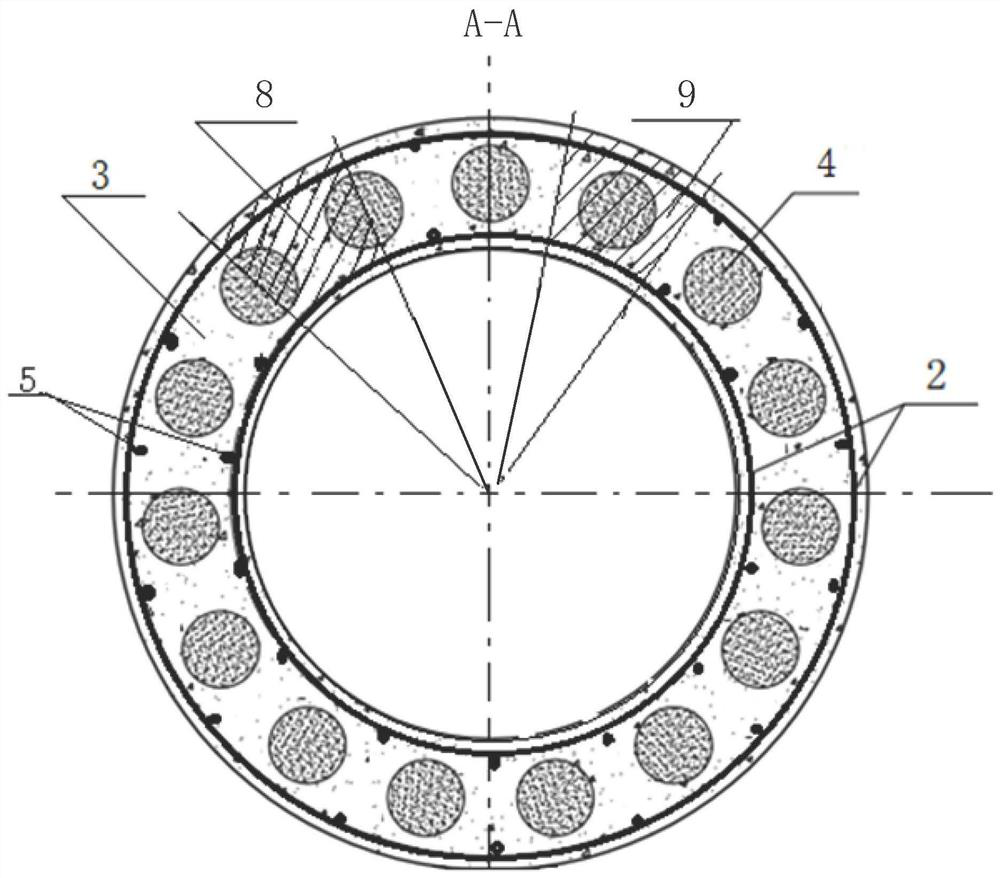

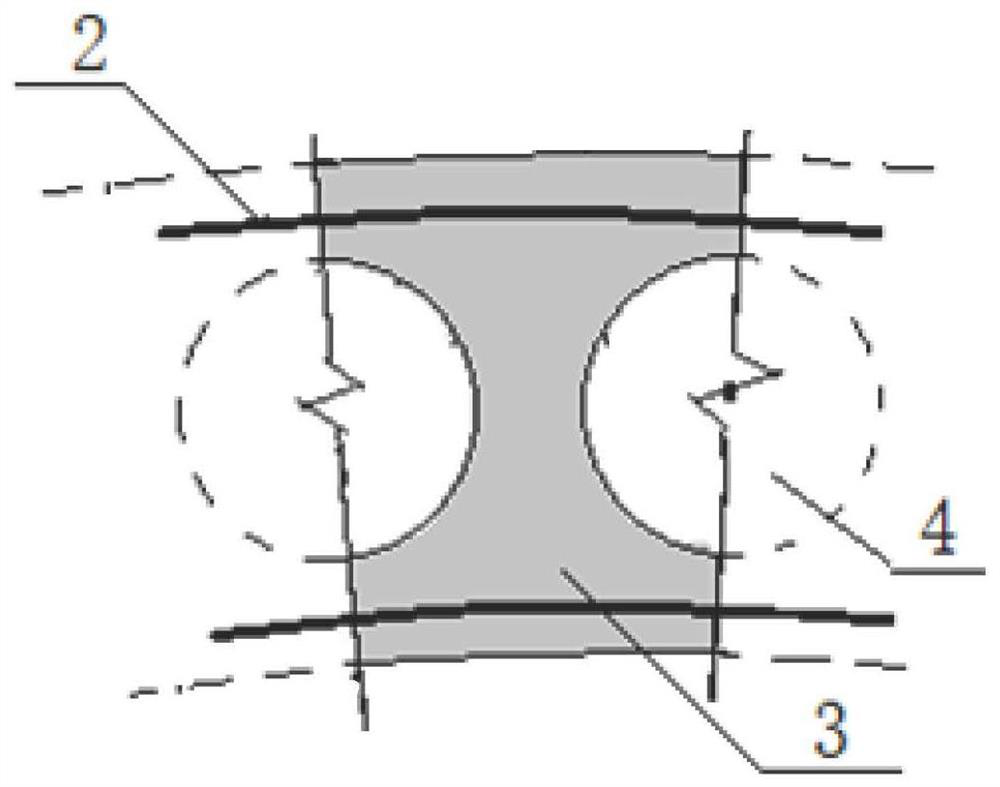

[0037] see Figure 1 to Figure 4 As shown, the water delivery pipeline provided in this embodiment includes a pipe body 3 , a filling part 4 , a multi-layer reinforcement layer assembly, a socket piece 6 and a socket piece 7 .

[0038] Hereinafter, the above-mentioned components of the water delivery pipeline will be described in detail.

[0039] In the optional solution of this embodiment, the material of the pipe body 3 includes UHPC, and UHPC is ultra-high performance concrete. Under the premise of not changing the size and specifications of the pipe, the pipe body 3 can meet the basic mechanical performance requirements. There is still a margin of mechanical properties.

[0040] In this embodiment, sockets 6 and sockets 7 are provided at both ends of the pipe body 3 in the axial direction, so as to connect a plurality of water delivery pipes sequentially through the sockets 6 and sockets 7 .

[0041] Along the axial direction of the pipe body 3, the two ends of the filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com