Flatness detection device for metal product processing

A technology of metal products and detection devices, which is applied in the direction of manufacturing tools, mechanical roughness/irregularity measurement, workbench, etc., can solve the problems of wrong flatness detection results, inability to re-engrave uneven places, damage, etc., to achieve Improve the smoothing effect, facilitate improvement and maintenance, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

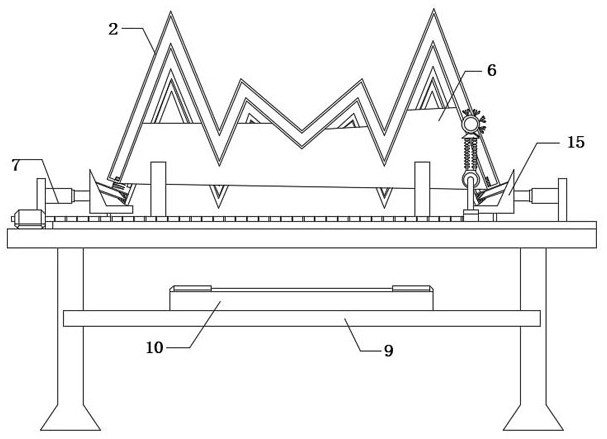

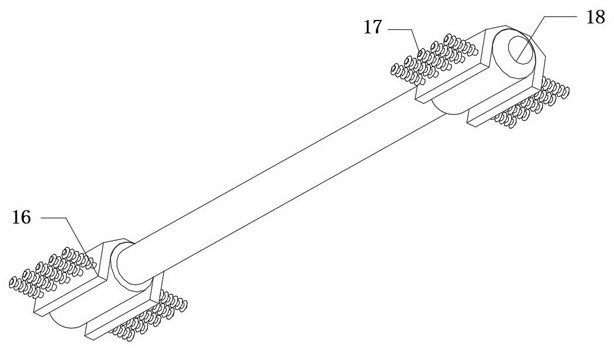

[0032] refer to figure 1 , figure 2 , Figure 5 and Image 6 , a flatness detection device for metal product processing, comprising a workbench 1 and a metal product body 5, a flexible fiberboard 3 is placed on the outer wall of the top plate of the metal product body 5, and the workbench 1 is located on the top outer wall at both ends of the metal product body 5 A clamping assembly is provided, guide rails 14 are fixedly connected to both ends of the top outer wall of the workbench 1, and sliders 25 are slidably connected to the inner walls of the two guide rails 14, and the top outer walls of the two sliders 25 are fixedly connected to Fixed rod 30, between the two fixed rods 30 is provided with a smoothing adjustment assembly, the top outer wall of the workbench 1 near the end of the guide rail 14 is fixedly connected with a push rod motor 8, and the electric push rod end of the push rod motor 8 is fixedly connected to the The outer wall of the slider 25.

[0033] In t...

Embodiment 2

[0039] refer to figure 1 , Figure 7 and Figure 8 , a flatness detection device for metal product processing, including a workbench 1, the outer walls of the workbench 1 at both ends of the metal product body 5 are fixedly connected with two side bars 11, and the two side bars 11 on one side The outer wall is fixedly connected with the same insulation board 6, the top outer wall of the insulation board 6 is fixedly connected with a guide frame 2, and the guide frame 2 is provided with a guide hole, and the rotating shaft 27 passes through the guide hole, and both ends of the bottom outer wall of the workbench 1 are fixedly connected There are support bases 13, and the outer walls of the same side of the two support bases 13 are fixedly connected with extension rods 12, the outer walls of the two extension rods 12 are fixedly connected with the same mounting plate 9, and the top outer wall of the mounting plate 9 is fixedly connected with a placement slot 10, and the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com