Integrated waveguide-coaxial-microstrip transition structure

A transitional structure and waveguide technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of high processing and assembly precision, difficulty in integration, poor consistency, etc., achieve low alignment requirements, reduce processing difficulty and cost , The effect of reducing the processing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

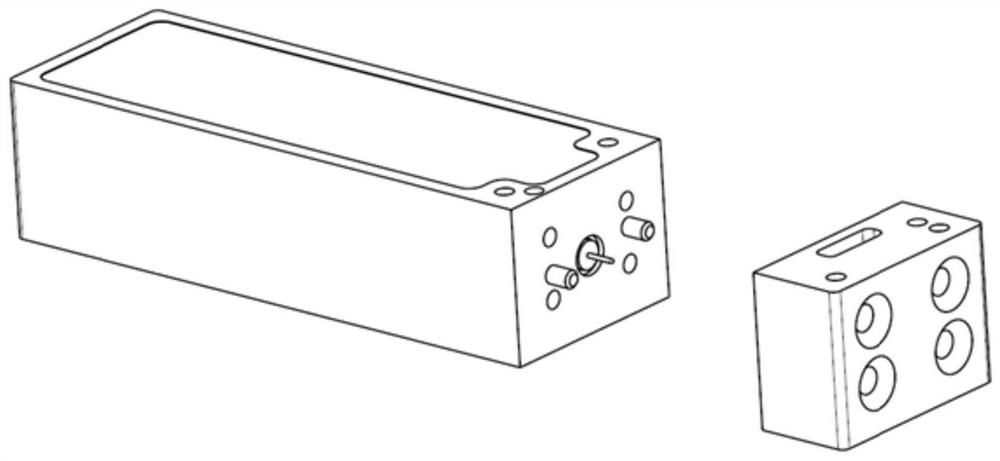

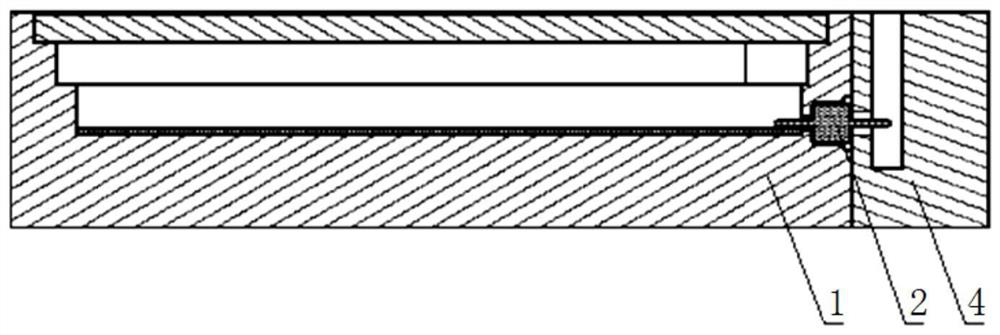

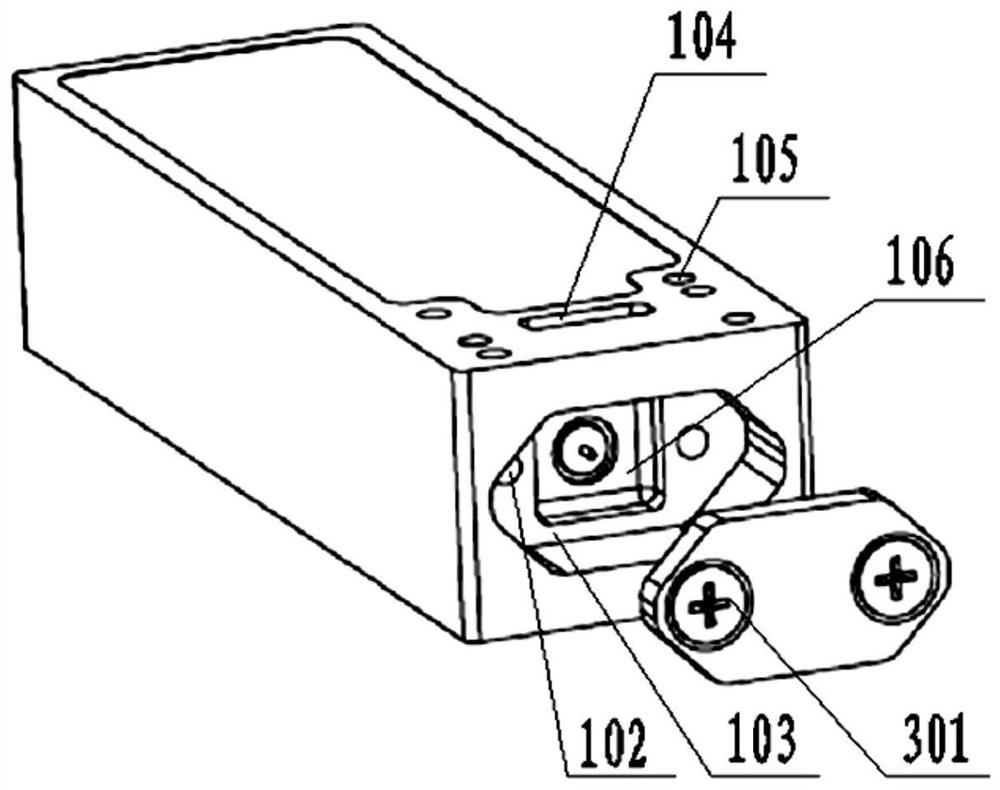

[0042] Such as image 3 and 4As shown, this embodiment provides an integrated waveguide-coaxial-microstrip transition structure, including a microwave box body 1, an insulator 2, and a waveguide cover plate 3, wherein the top surface of the microwave box body 1 is provided with a circuit groove in the depth direction To install the microwave circuit, a cover plate 101 is arranged above the circuit slot. One end surface of the microwave box body 1 is provided with an end surface groove 103, and the waveguide cover plate 3 is closely matched with the end surface groove 103. An end face waveguide cavity 106 is arranged in the end face groove 103, an external waveguide port 104 is arranged on the corresponding position above the end face waveguide cavity 106, that is, the top surface of the microwave box body 1, and waveguide installation holes 105 are arranged on both sides of the external waveguide port 104. The insulator 2 is arranged laterally between the end face waveguide ...

Embodiment 2

[0056] This embodiment is on the basis of embodiment 1:

[0057] Such as Figure 5 As shown, the waveguide signal of the integrated waveguide-coaxial-microstrip transition structure is input from the top, the insulator 2 directly penetrates into the waveguide cavity 106 on the end face without passing through the air cylindrical cavity, and the waveguide signal is coupled and output by the conductor probe inside the insulator 2. This embodiment The size of the selected waveguide is 7.12mm×3.56mm. For the convenience of digital milling, the rounded corner of the waveguide is R0.5mm.

[0058] The diameter of the inner conductor of the insulator 2 is 0.3 mm, and the distance between the center and the bottom surface of the end face waveguide cavity 106 (waveguide short-circuit surface) is about a quarter of the wavelength of the center frequency, that is, 1.85 mm. About half of the side, the depth of the insulator 2 in this embodiment into the end face waveguide cavity 106 is 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com