A kind of mpp cable tube which is convenient for welding and installation

A technology of cable pipes and fusion pipes, which is applied in the field of MPP pipes, can solve problems such as easy cracking, difficulty in controlling welding accuracy, and easy to cause pipe quality problems, achieving the effect of high butt joint accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

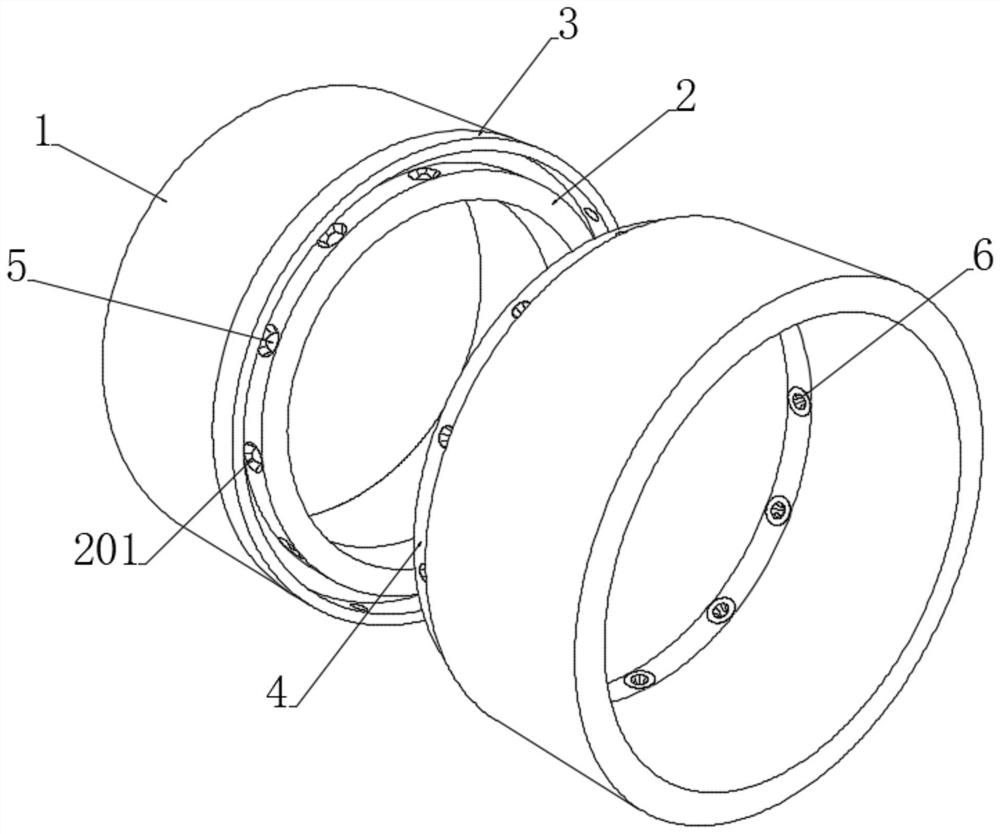

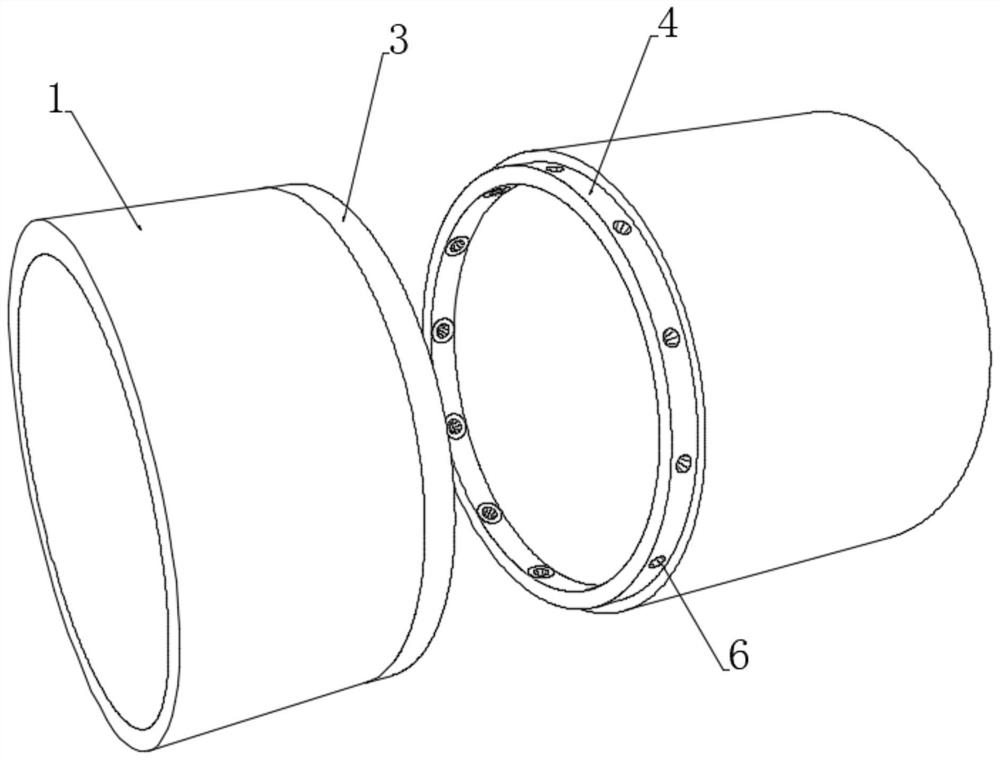

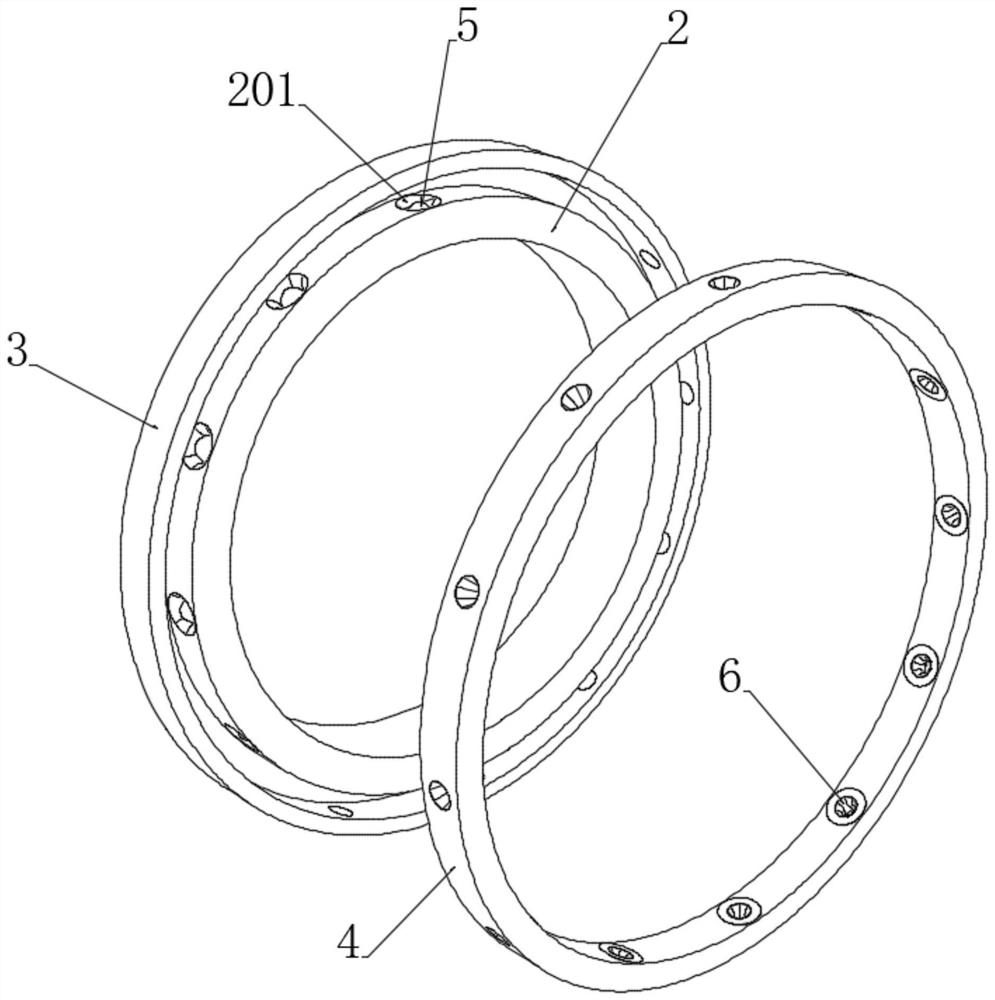

[0045] see Figure 1-3 and Figure 6-7 , an MPP cable tube that is convenient for welding and installation, comprising a pair of tube bodies 1 to be welded and installed, a pair of butt ends of the tube bodies 1 are respectively provided with a left butt joint and a right butt joint, and the left butt joint and the right butt joint are used for mutual butt joints. The subsequent welding realizes the connection and installation between a pair of pipe bodies 1, wherein the left butt joint includes an inner connecting pipe 2 and an outer connecting pipe 3 sleeved on the inner and outer walls of the pipe body 1, and the pipe body 1 is located inside the outer connecting pipe 3. , an annular butt cavity is formed between the pipe body 1 and the outer connecting pipe 3, the right butt joint includes a fusion pipe 4 connected to the other pipe body 1, the fusion pipe 4 is embedded in the annular butt cavity, and the inner connection pipe 2 faces outwards A plurality of placement cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com