Cement plate and manufacturing method thereof

A board and cement technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems that plastering mortar is not as good as red brick, single function, wall cracks, etc., so that it is not easy to crack the wall , Uniform color, not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

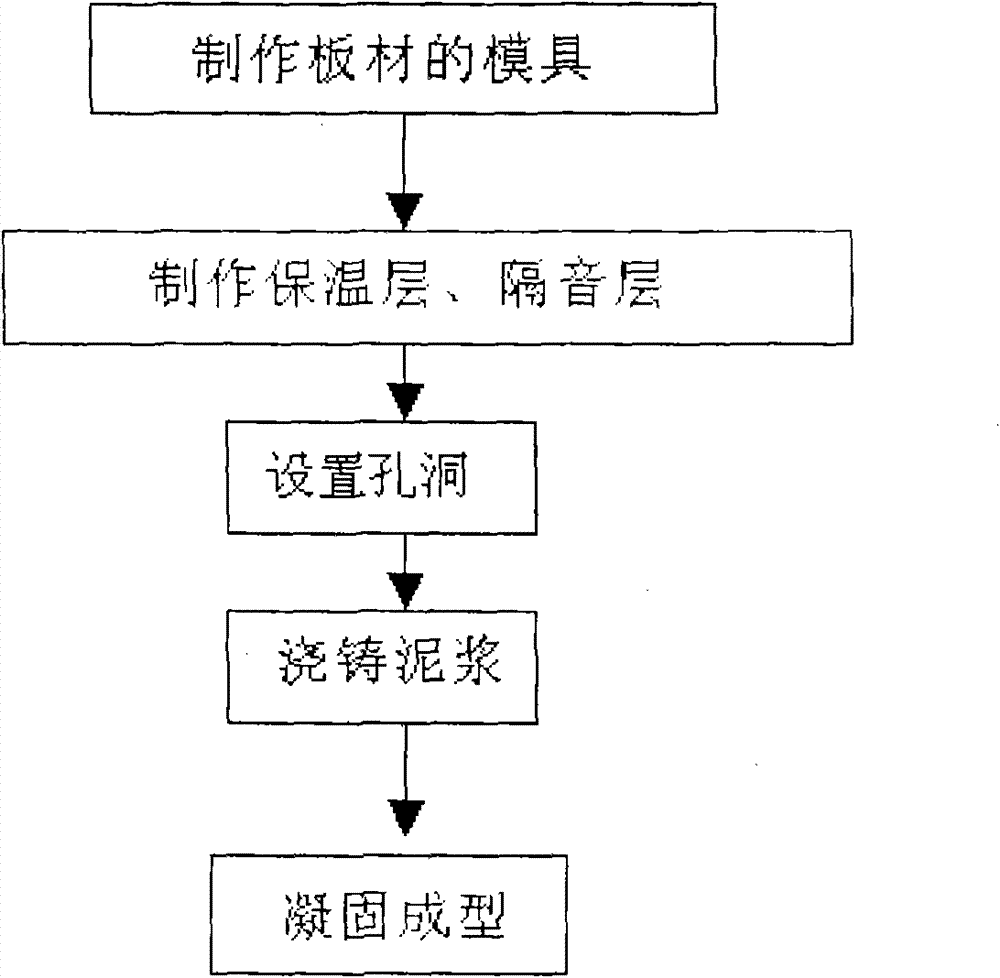

Method used

Image

Examples

Embodiment 1

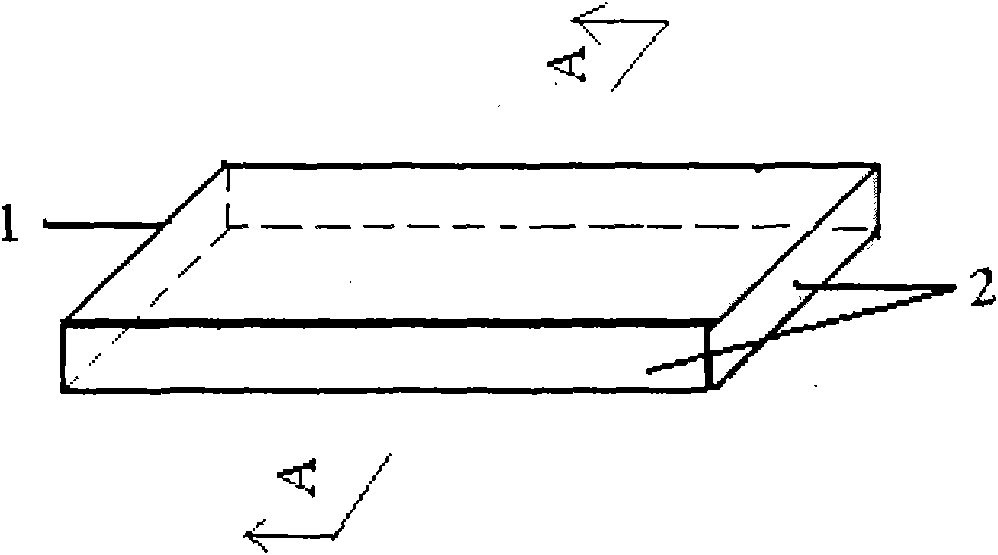

[0030] Such as figure 1 , figure 2 As shown, taking the quadrilateral cement board as an example, its content is: the weight percentage of each component is Portland cement 5%, anhydrous chloride 12%, magnesium oxide 30%, magnesium sulfate 7%, anhydrous gypsum powder 8% , fly ash 25%, rice husk 10%, and the rest are additives; additives are phosphoric acid, gelatin, three sodium, polypropylene fiber.

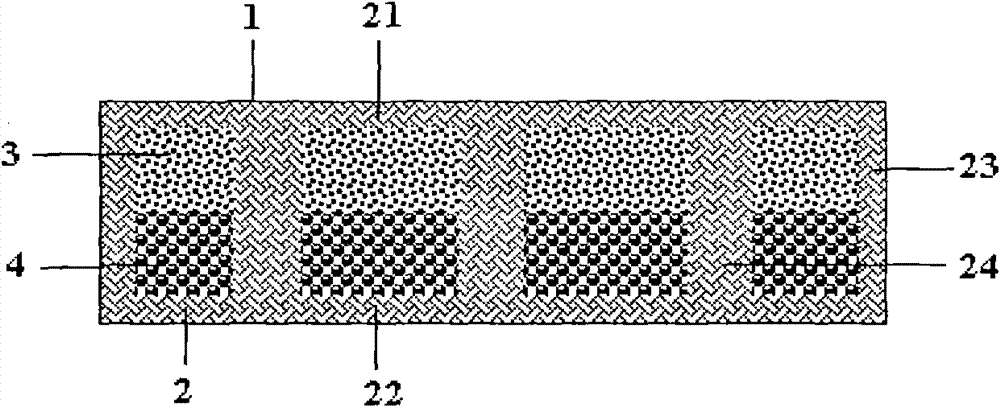

[0031] The surface of the cement board is fully enclosed, including an insulation layer 3, a sound insulation layer 4 and an enclosure support frame 2; the enclosure support frame 2 is formed at one time, including a top layer 21, a bottom layer 22, a peripheral frame 23 and a support column 24, The support column 24 is perpendicular to the top layer 21 and the bottom layer 22 and connected with them, so as to stabilize the frame structure of the cement board, not easy to deform, and improve the compressive strength of the cement board. The side length of the cement board is ...

Embodiment 2

[0040] A cement board, the content of which is: Portland cement 8%, anhydrous magnesium chloride 10%, magnesium oxide 25%, magnesium sulfate 11%, anhydrous gypsum powder 5%, fly ash 30% in weight percentage of each component , 12% of rice husk, and the rest are additives; said additives include phosphoric acid, gelatin, three sodium, polypropylene fibers.

[0041] The surface of the cement board is fully enclosed, including an insulation layer 3, a sound insulation layer 4 and an enclosure support frame 2; the enclosure support frame 2 is formed at one time, including a top layer 21, a bottom layer 22, a peripheral frame 23 and a support column 24, The support column 24 is perpendicular to the top layer 21 and the bottom layer 22 and connected with them, so as to stabilize the frame structure of the cement board, not easy to deform, and improve the compressive strength of the cement board. The side length of the cement board is 600mm×1200mm, and the thickness is 60mm. The ins...

Embodiment 3

[0050] A cement board, wherein the components: Portland cement 6%, anhydrous magnesium chloride 11%, magnesium oxide 28%, magnesium sulfate 9%, anhydrous gypsum powder 6%, fly ash 29%, rice 11% of the shell, and the rest are additives; the additives include phosphoric acid, gelatin, three sodium, polypropylene fibers.

[0051] The surface of the cement board is fully enclosed, including the insulation layer 3, the sound insulation layer 4 and the enclosure support frame 2; the enclosure support frame 2 is formed at one time, including the top layer 21, the bottom layer 22, the peripheral frame 23 and the support column 24. The support column 24 is perpendicular to the top layer 21 and the bottom layer 22 and connected with them, so as to stabilize the frame structure of the cement board, not easy to deform, and improve the compressive strength of the cement board. The side length of the cement board is 400mm×1000mm, and the thickness is 40mm. The insulation layer is composed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com