Anti-dislocation artificial temporomandibular joint prosthesis

A temporomandibular joint and prosthesis technology, applied in the field of anti-dislocation artificial temporomandibular joint prosthesis, can solve problems such as sagging, dislocation out of the joint socket, the artificial joint prosthesis and the muscle cannot form re-attachment, etc., to expand the scope of application, Improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

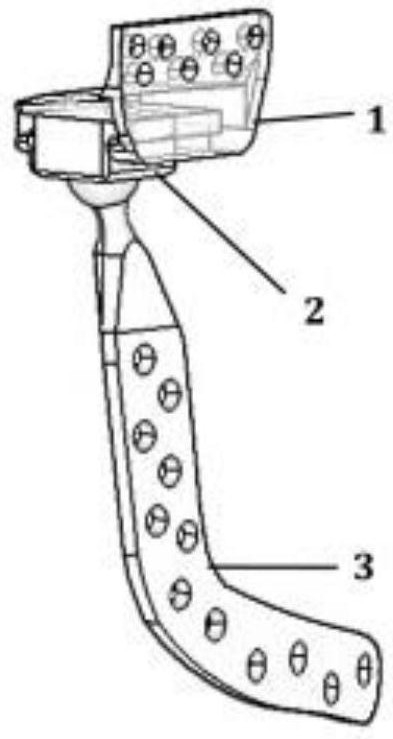

[0032] see Figure 1-9 According to an embodiment of the present invention, an anti-dislocation artificial temporomandibular joint prosthesis includes a glenoid prosthesis 1 and a slider body 2 slidingly connected with the glenoid prosthesis 1, and also includes a Mandibular ramus prosthesis with rolling connection3.

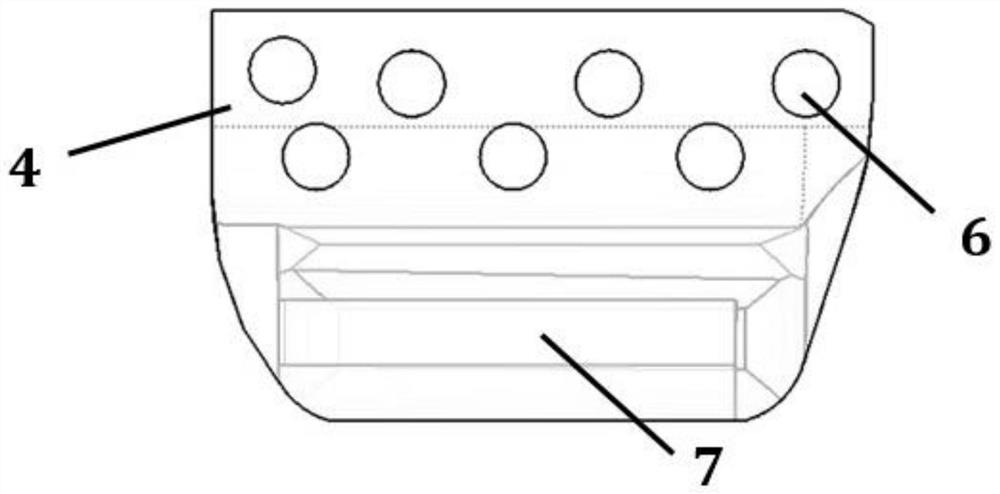

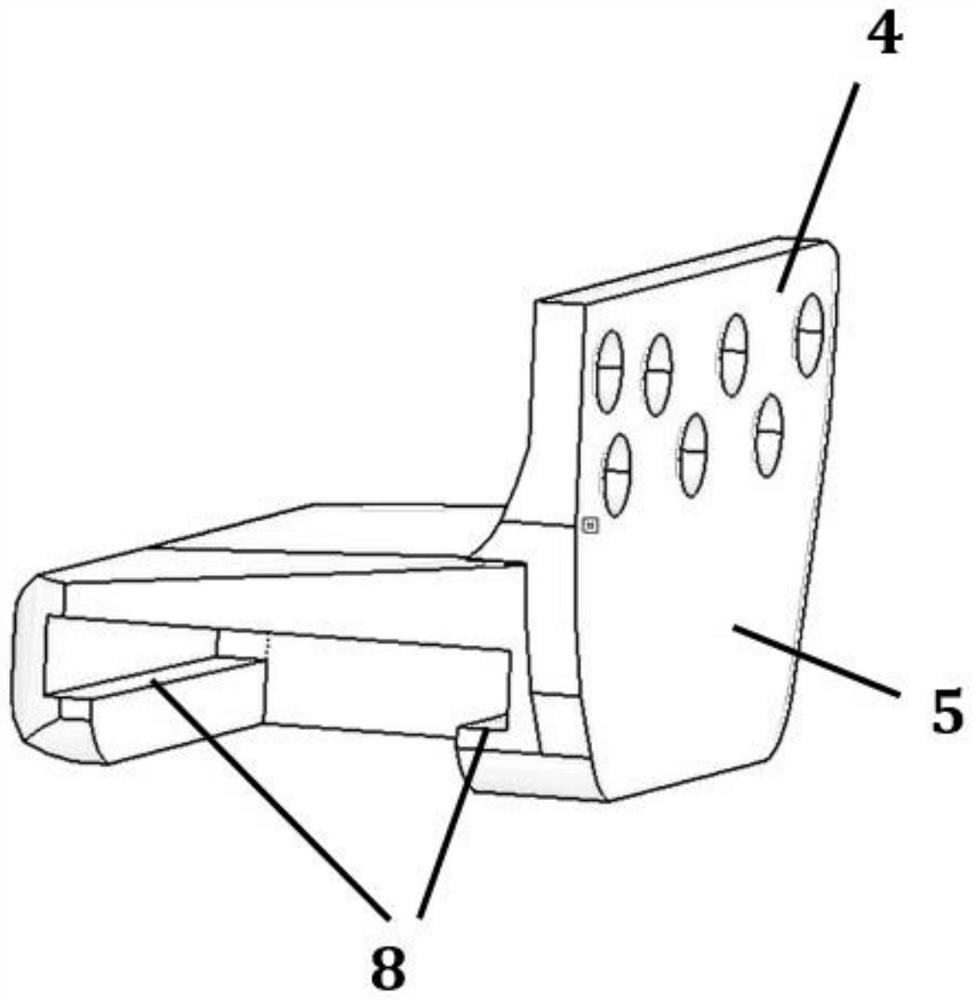

[0033] The glenoid prosthesis 1 includes the glenoid socket 5 arranged on both sides thereof, the glenoid base 4 arranged above the glenoid socket 5 on one side, and the glenoid socket 5 arranged between the two glenoid sockets 5 The chute 7 in between, the chute supporting surfaces 8 arranged on both sides of the bottom of the chute 7, and the front end wall 9 arranged at one end of the chute.

[0034] The slider body 2 includes snap wings 10 arranged on both sides thereof, and a spherical concave surface 12 arranged at the bottom of the slider body 2 .

[0035] The mandibular ramus prosthesis 3 includes a condyle head 13, a condyle neck 14 fixedly connected ...

Embodiment 2

[0039] 6-8 base screw holes 6 with a diameter of 2.2-2.5 mm are uniformly arranged on the base of the glenoid fossa 4 to ensure that the connection between the base of the glenoid fossa 4 and the zygomatic arch does not loosen and has sufficient rigidity and strength 10-13 retention handle screw holes 16 with a diameter of 4.3-4.5 mm are evenly arranged on the mandibular ramus retention handle 15 to ensure multi-point rigid connection between the mandibular ramus retention handle 15 and the mandibular ramus , with sufficient rigidity and strength.

Embodiment 3

[0041] The glenoid prosthesis 1 is made of ultra-high molecular polyethylene polymer, which has good corrosion resistance, anti-scaling, anti-aging, and wear resistance. The glenoid base 4 and the glenoid socket 5 are The one-piece structure has a simple structure and ensures the rigidity and strength requirements of the glenoid prosthesis 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap