Preparation method and production equipment of super-strong sound insulation building decoration material

A technology for building decoration materials and production equipment, which is applied in the direction of architecture, building components, and building structures, and can solve problems such as unfavorable enterprise development, increased labor costs, and time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

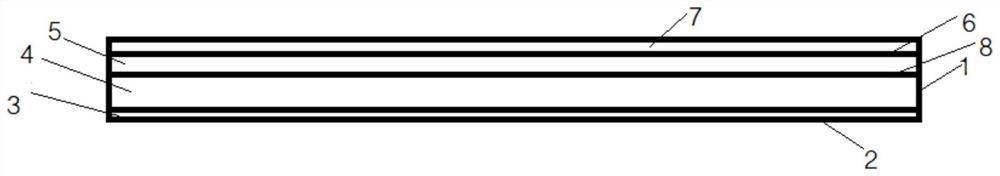

[0033] see figure 1 , a preparation method of a super-strong sound-insulating building decoration material, comprising the following construction steps:

[0034] A. Prepare the sound-insulating metal layer 1; the sound-insulating metal layer 1 is a rectangular box shape with an upper opening and a surrounding wall and a bottom, and is integrally formed by a rolling process;

[0035] B. Coating a sound-insulating viscous layer 2 inside the sound-insulating metal layer 1; the sound-insulating viscous layer 2 is composed of viscous materials including resin, and is coated on the inner bottom surface and surrounding barriers of the sound-insulating metal layer 1 The inner surface of the wall, the height of the coating is the thickness of the sound-insulating fiber cloth layer 3;

[0036] C. bonding the sound-insulating fiber cloth layer 3 on the sound-insulating viscous layer 2; appropriate pressure may be applied during the process of bonding the sound-insulating fiber cloth lay...

Embodiment 2

[0049] see figure 1 , a preparation method of a super-strong sound-insulating building decoration material, comprising the following construction steps:

[0050] A. Prepare the sound-insulating metal layer 1; the sound-insulating metal layer 1 is a rectangular box shape with an upper opening and a surrounding wall and a bottom, and is integrally formed by a rolling process;

[0051] B. Coating a sound-insulating viscous layer 2 inside the sound-insulating metal layer 1; the sound-insulating viscous layer 2 is composed of viscous materials including resin, and is coated on the inner bottom surface and surrounding barriers of the sound-insulating metal layer 1 The inner surface of the wall, the height of the coating is the thickness of the sound-insulating fiber cloth layer 3;

[0052] C. bonding the sound-insulating fiber cloth layer 3 on the sound-insulating viscous layer 2; appropriate pressure may be applied during the process of bonding the sound-insulating fiber cloth lay...

Embodiment 3

[0069] see figure 1 , a preparation method of a super-strong sound-insulating building decoration material, comprising the following construction steps:

[0070] A. Prepare the sound-insulating metal layer 1; the sound-insulating metal layer 1 is a rectangular box shape with an upper opening and a surrounding wall and a bottom, and is integrally formed by a rolling process;

[0071] B. Coating a sound-insulating viscous layer 2 inside the sound-insulating metal layer 1; the sound-insulating viscous layer 2 is composed of viscous materials including resin, and is coated on the inner bottom surface and surrounding barriers of the sound-insulating metal layer 1 The inner surface of the wall, the height of the coating is the thickness of the sound-insulating fiber cloth layer 3;

[0072] C. bonding the sound-insulating fiber cloth layer 3 on the sound-insulating viscous layer 2; appropriate pressure may be applied during the process of bonding the sound-insulating fiber cloth lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com