Rocket launching vehicle erecting hydraulic system with negative load adjusting function and adjusting method

A technology for rocket launch and hydraulic system, which is applied to rocket launch devices, fluid pressure actuating system components, fluid pressure actuating devices, etc., can solve problems such as negative load stall, and achieve the effects of reasonable setting, simple structure and reliable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

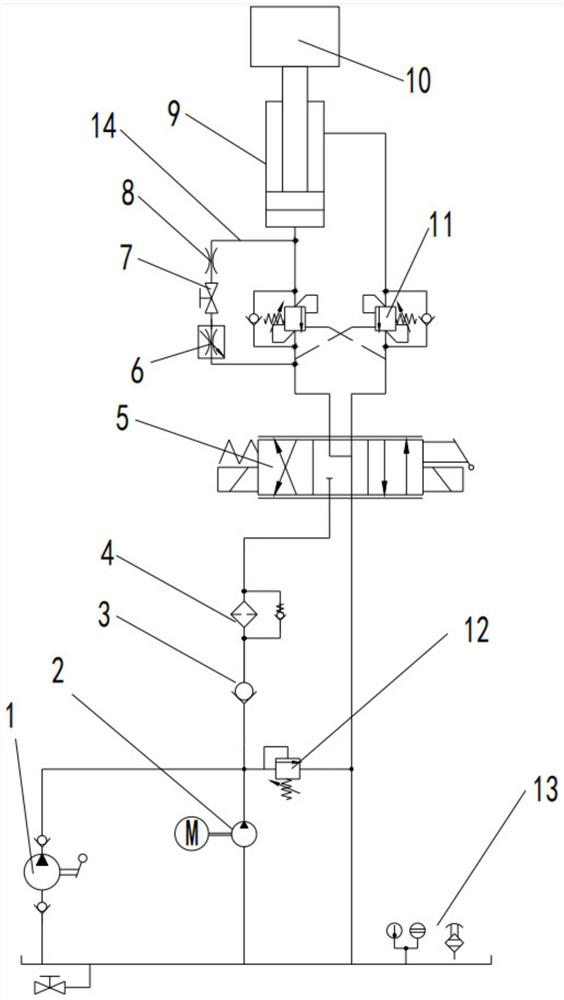

[0018] Such as figure 1 Shown: a rocket launch vehicle vertical hydraulic system with negative load adjustment function, including: lifting system, slow down speed control system; the slow down speed control system is installed in parallel on the lifting system through pipelines and pipe heads;

[0019] The lifting system includes: fuel tank assembly 13, motor oil pump group 2, check valve 3, reversing valve 5, hydraulic pressure retaining element 11, actuator 9; the fuel tank assembly 13, motor oil pump group 2, and actuator 9 pass through the pipe The hydraulic circuit and the pipe head constitute a hydraulic circuit, and they are power-connected to each other; the check valve 3, the reversing valve 5, and the hydraulic holding element 11 are sequentially arranged between the motor oil pump unit 2 and the actuator 9;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com