Rare earth metal production smelting furnace with tail gas treatment function

A technology of tail gas treatment and rare earth metals, which is applied in waste heat treatment, furnaces, furnace components, etc., can solve the problems of clean disposal of harmful substances, hidden dangers of harmful gases discharged from exhaust pipes, etc., and achieve the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

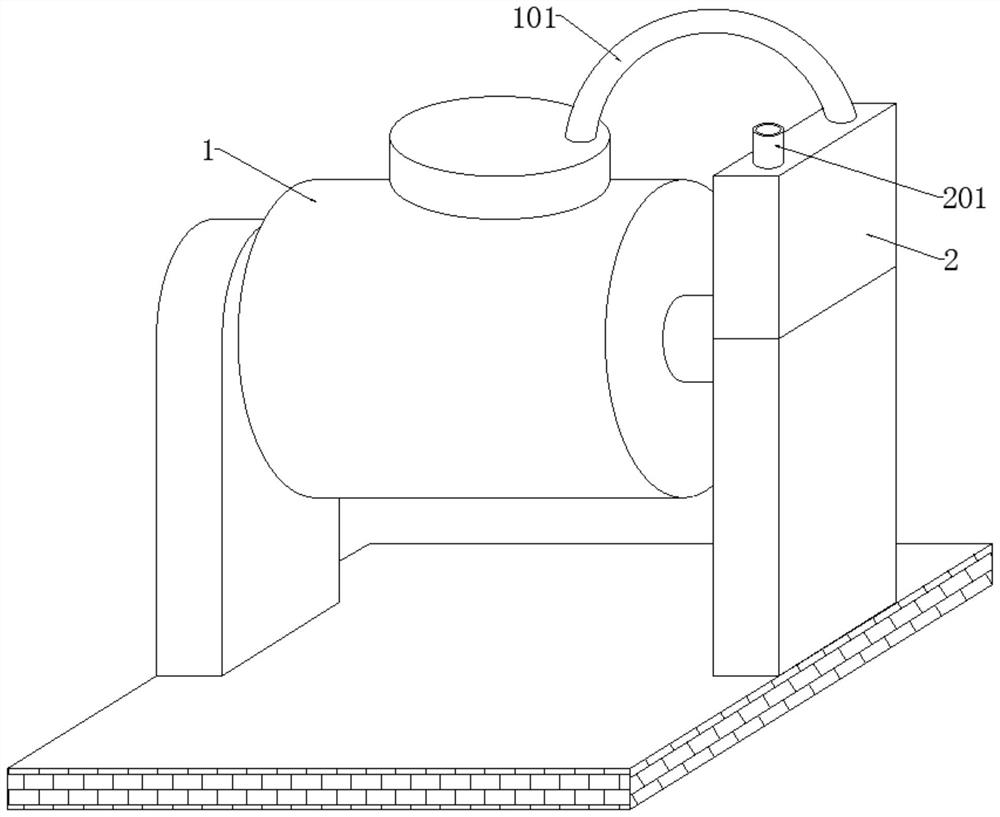

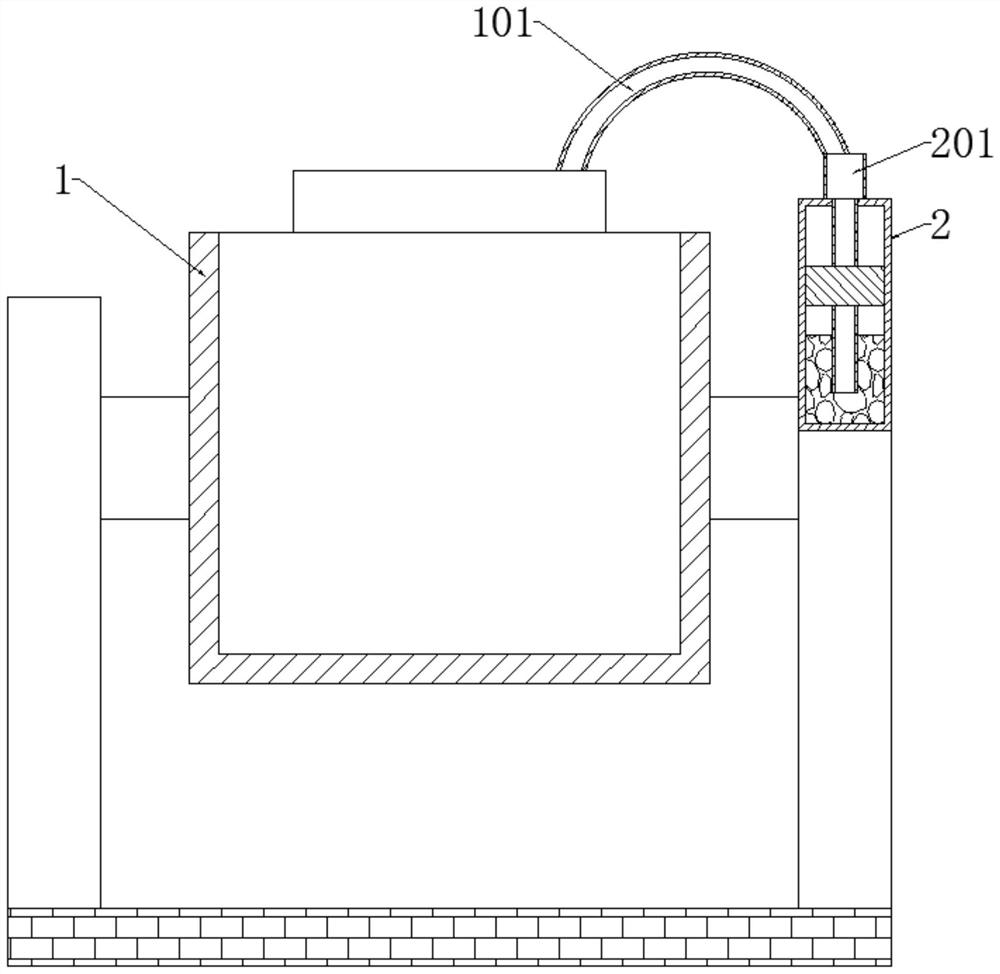

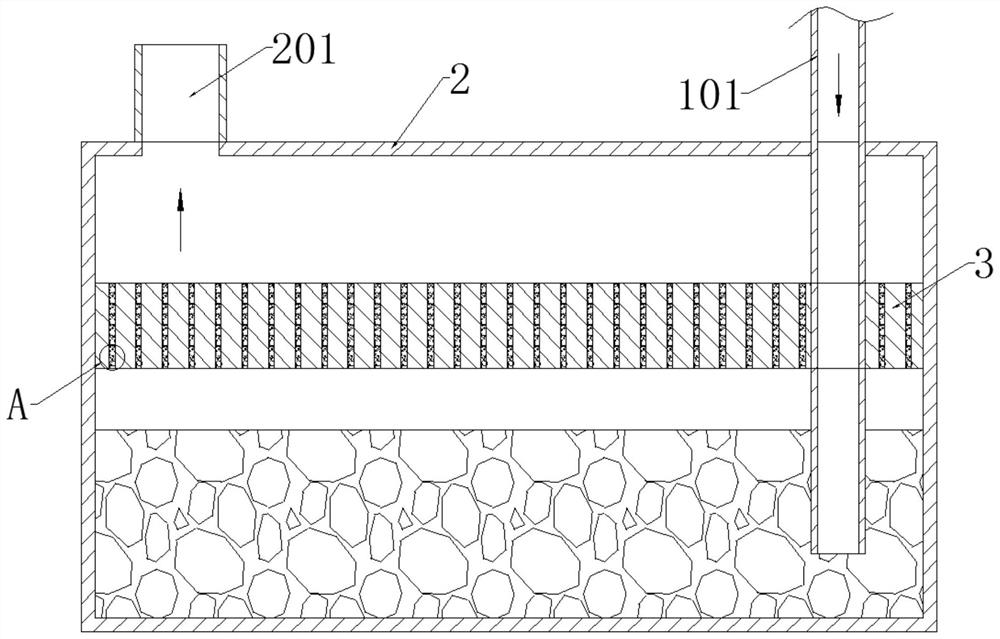

[0036] see Figure 1-5 , in an embodiment of the present invention, a smelting furnace with tail gas treatment for rare earth metal production, including a furnace body 1, an exhaust hose 101, a water tank 2 and an exhaust pipe 201, and the middle upper end of the water tank 2 is fixed in a horizontal direction A filter plate 3 is installed, and the internal positions of the filter plate 3 are arranged in equal rows and fixedly installed with several filter tubes 4 up and down. Exhaust filter assembly 5;

[0037] Each set of filter assemblies 5 includes a guide channel 501 , a casing 502 , a guide channel 503 , a flow control assembly 504 capable of controlling the flow of exhaust gas, and a net flow assembly 505 capable of purifying exhaust gas.

[0038] In the embodiment of the present invention, activated carbon powder 6 is filled between every two adjacent groups of filter assemblies 5 and the inner wall of each filter tube 4;

[0039] The active carbon powder 6 here and i...

Embodiment 2

[0044] see Figure 5 Compared with Embodiment 1, this embodiment of the present invention differs in that each group of flow control components 504 includes a rotating shaft 5041 , a balance plate 5042 and a contact block 5043 .

[0045] In the embodiment of the present invention, each rotating shaft 5041 is rotatably mounted on the inner wall of each housing 502 in a front-rear horizontal direction, and a balance plate 5042 is fixedly installed around the outer surface of each rotating shaft 5041. Each balance plate 5042 are in a horizontal static equilibrium state under normal circumstances, the outer surface of the left end of each balance plate 5042 is surrounded by a filter screen, and the top position of the tail of the right end of each balance plate 5042 is fixedly equipped with a contact block 5043. The appearance of the block 5043 is in the shape of a letter T in a longitudinal section;

[0046] The balance plate 5042 here is to absorb and filter the exhaust gas int...

Embodiment 3

[0049] see Figure 5-7 Compared with Embodiment 1, the embodiment of the present invention differs in that each set of net flow components 505 includes a fixing plate 5051 , an air bag 5052 and a cleaning agent 5053 .

[0050] In the embodiment of the present invention, each fixing plate 5051 is fixedly installed in the middle of the upper end of the inner wall of each housing 502 in the front and rear horizontal direction. Airbags 5052 are fixedly installed on the inner surface of the top side of the plate 5051, and the outer surface of the top side of each airbag 5052 is normally attached to the inner wall of each housing 502, and the inner position of each airbag 5052 is pre-installed Purifier 5053;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com