Dynamic CO detection device for pulverized coal preparation

A detection device, coal powder preparation technology, applied in the direction of measuring device, test sample preparation, cleaning method and utensils, etc., can solve the problem of CO analysis instrument not working normally, complex flue gas composition at coal mill outlet, flue gas dust Large particles and other problems, to achieve the effect of prolonging the heating time, prolonging the service life and increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

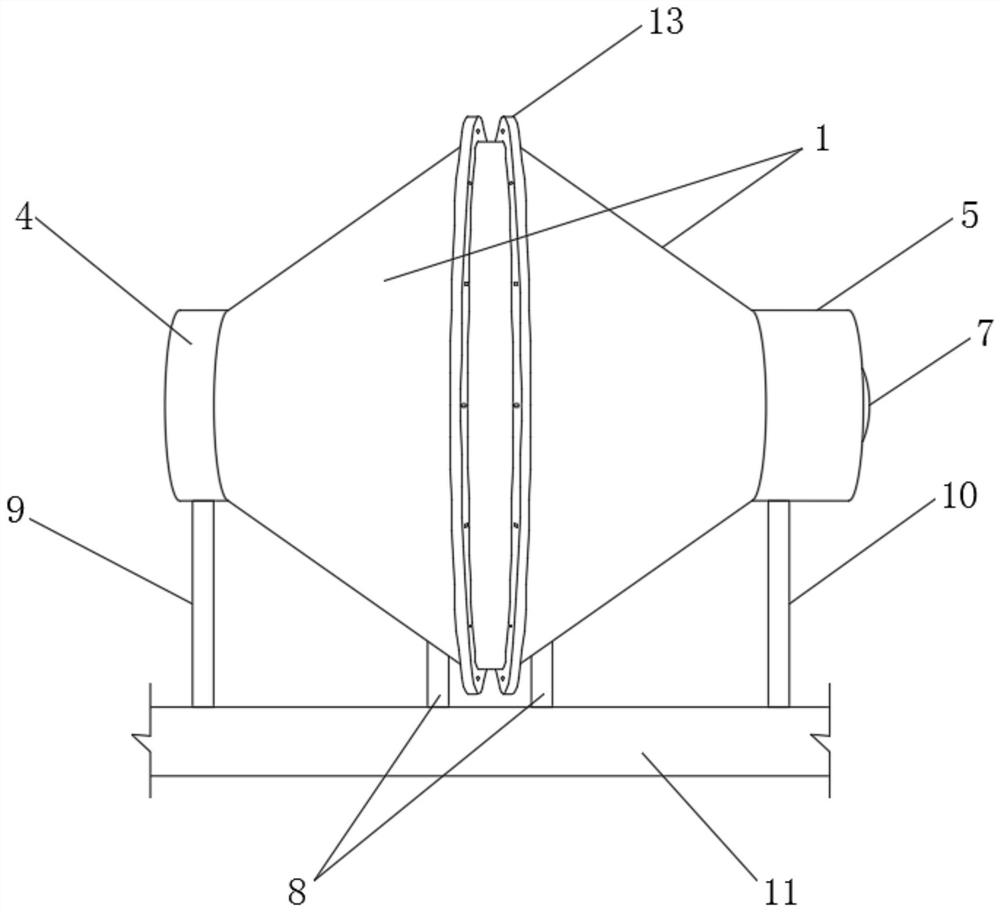

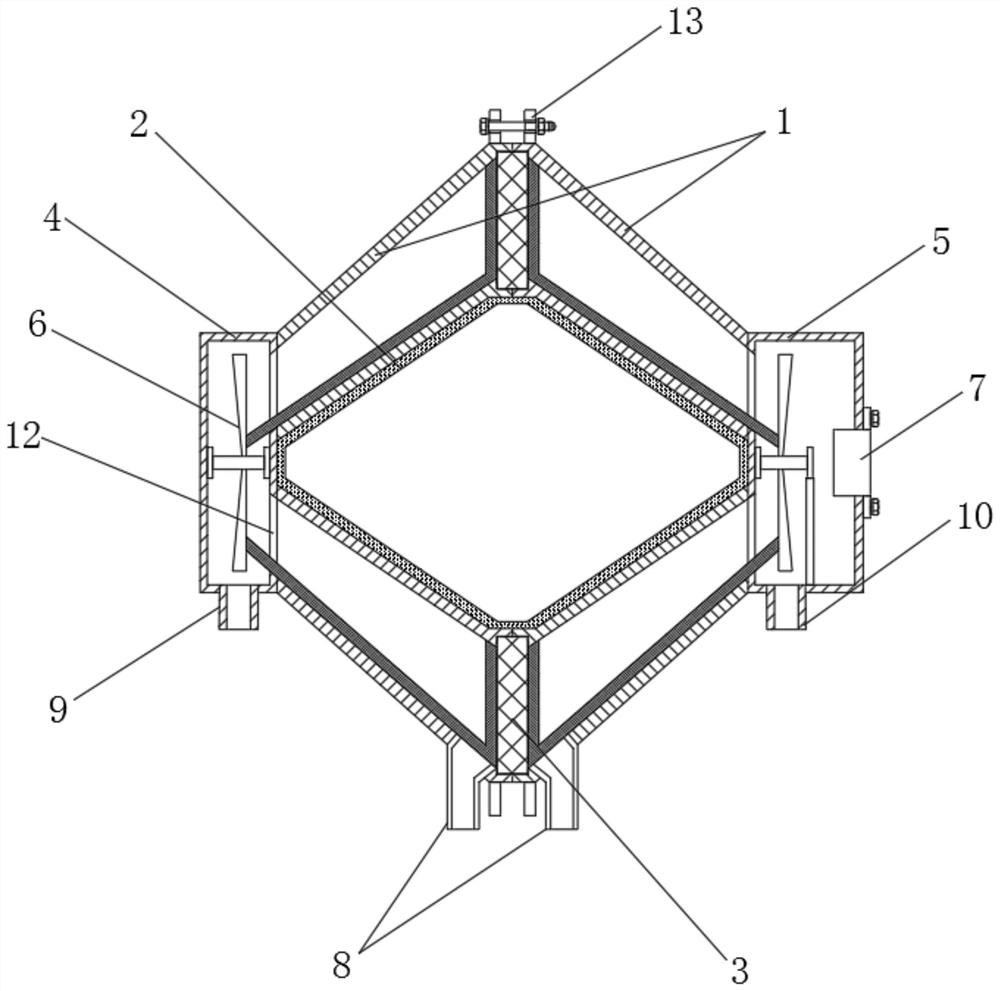

[0030] Such as Figure 1-3 As shown, a dynamic CO detection device for coal powder preparation includes two hollow heating boxes 1 arranged in a horn shape and corresponding to the horn openings, a heating assembly 2 arranged in the horn openings of the two hollow heating boxes 1, and The filter structure 3 outside the heating assembly 2 and connected to the two hollow heating boxes 1, the air inlet box 4 and the air outlet box 5, which are respectively arranged at one end of the two hollow heating boxes 1 and communicated with the hollow heating box 1, are respectively arranged at the inlet In the gas box 4 and the gas outlet box 5, a cleaning assembly 6 for cleaning the inner wall of the hollow heating box 1 and the filter structure 3, and a CO analyzer 7 detachably installed in the gas outlet box 5;

[0031] The cleaning assembly 6 includes a fan blade 61, an upper scraper 62 and a lower scraper 63 fixed on the fan blade 61, and one end of the upper scraper 62 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com