Forming method of micro-cantilever probe based on coupling effect of electric field and femtosecond laser

A femtosecond laser and micro-cantilever technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problems of complex temperature field, affecting probe detection accuracy, affecting probe size accuracy, etc. , to achieve the effect of simple manufacturing and processing, improving dimensional accuracy, and simple and effective methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described and illustrated through preferred embodiments below.

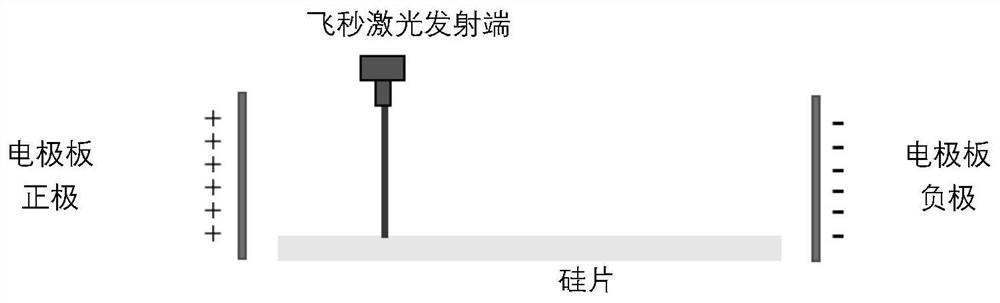

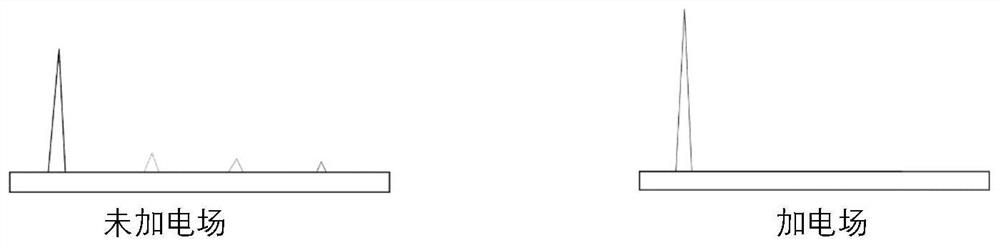

[0026] This embodiment is based on the forming method of the micro-cantilever beam probe coupled with electric field and femtosecond laser, and the specific operation steps are as follows:

[0027] Step 1: Prepare a silicon wafer with a size in the micronano range and place it under a high-precision microscope. The silicon wafer is in the shape of a cube, with a size of 25×700×1.5μm 3 . The length and width of the silicon chip are on the order of microns, and the height of the silicon chip is on the order of nanometers. Ensure that the surface of the silicon wafer is smooth and clearly visible under a high-precision microscope.

[0028] Step 2: Fix the middle position of the silicon wafer to ensure that the silicon wafer does not move after being fixed. Adjust femtosecond laser performance parameters. Forming is performed on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com