Reactor pressure vessel main pipeline nozzle internal inspection equipment

A technology for pressure vessels and main pipes, which is applied in the field of internal inspection equipment for reactor pressure vessel main pipe nozzles, can solve problems such as inability to accurately control cameras, inaccurate inspection results, safety accidents in nuclear power plants, etc., to achieve less nuclear island resources, The effect of saving the overhaul period and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

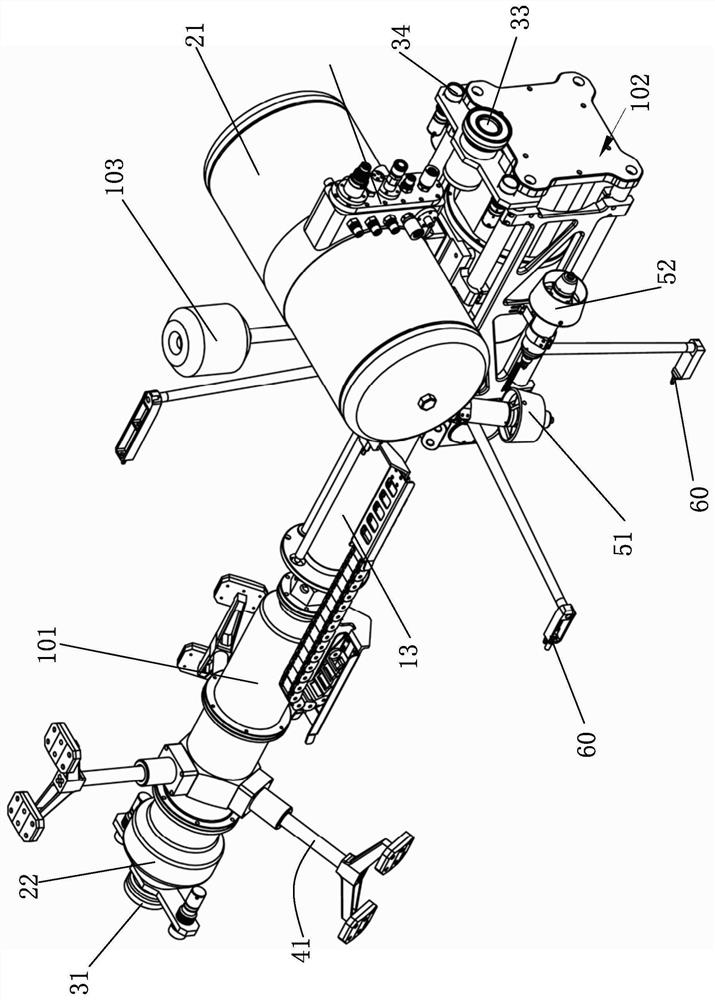

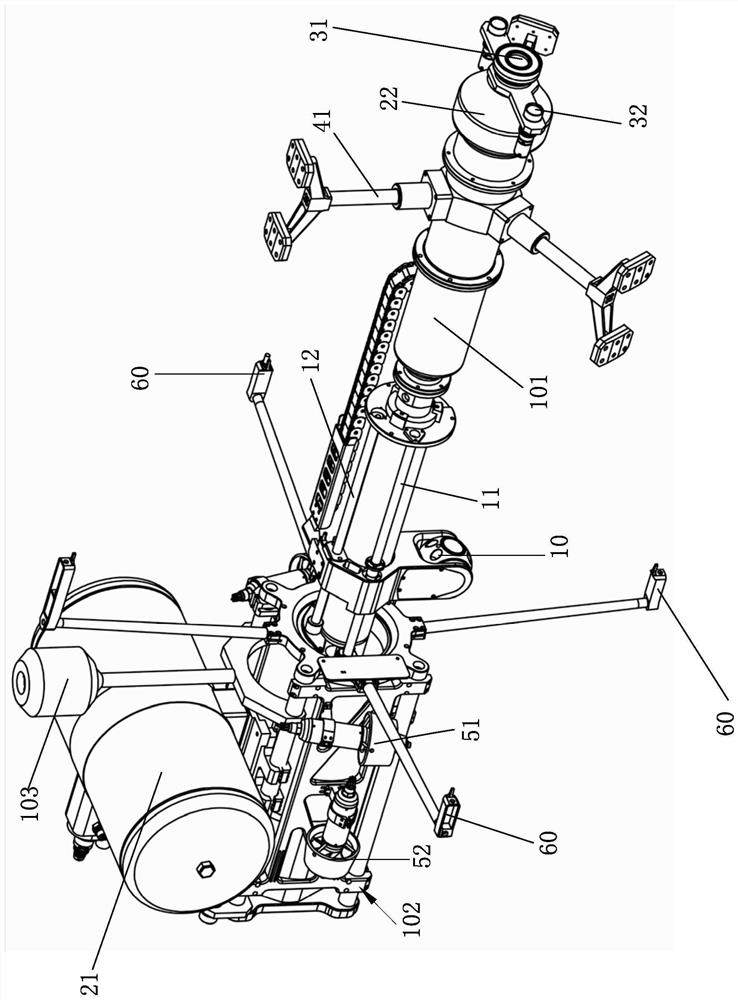

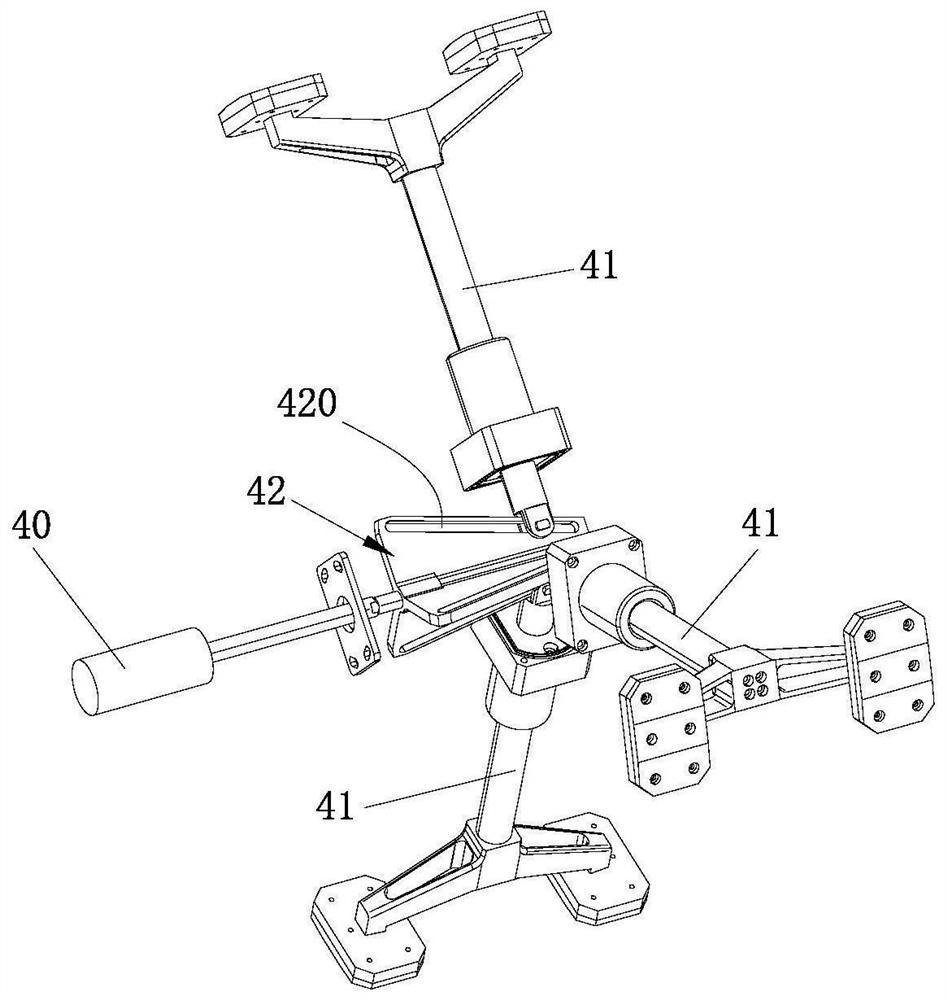

[0024] Such as Figure 1 to Figure 5 As shown, an internal inspection device for the main pipe nozzle of a reactor pressure vessel. The inspection device includes a diving inspection mechanism, a positioning mechanism, and a control module for controlling the action of the diving inspection mechanism and the positioning mechanism. The diving inspection mechanism includes a frame for inspecting the nozzle. The inspection module for internal defects, the buoyancy module for providing buoyancy, the power module for providing underwater movement power, the search module for exploring the underwater environment, and the positioning mechanism includes a position for inductive detection of the location of the diving inspection mechanism The detection component and the fixing component for fixing the position of the diving inspection mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com