Proton exchange membrane cell unit structure for hydrogen fuel cell

A proton exchange membrane and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of broken or loose connections, large resource loss, lack of connection structures, etc., to avoid sagging Or fall off, easy to slide installation, improve the effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

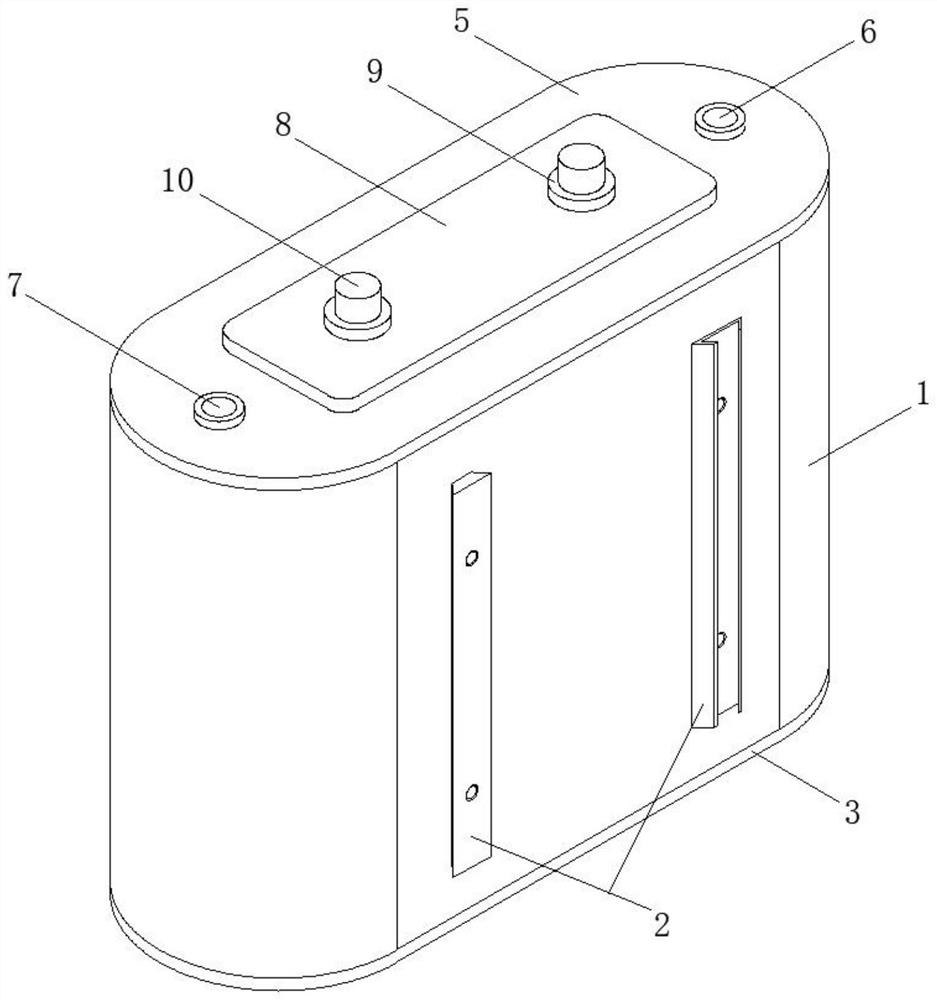

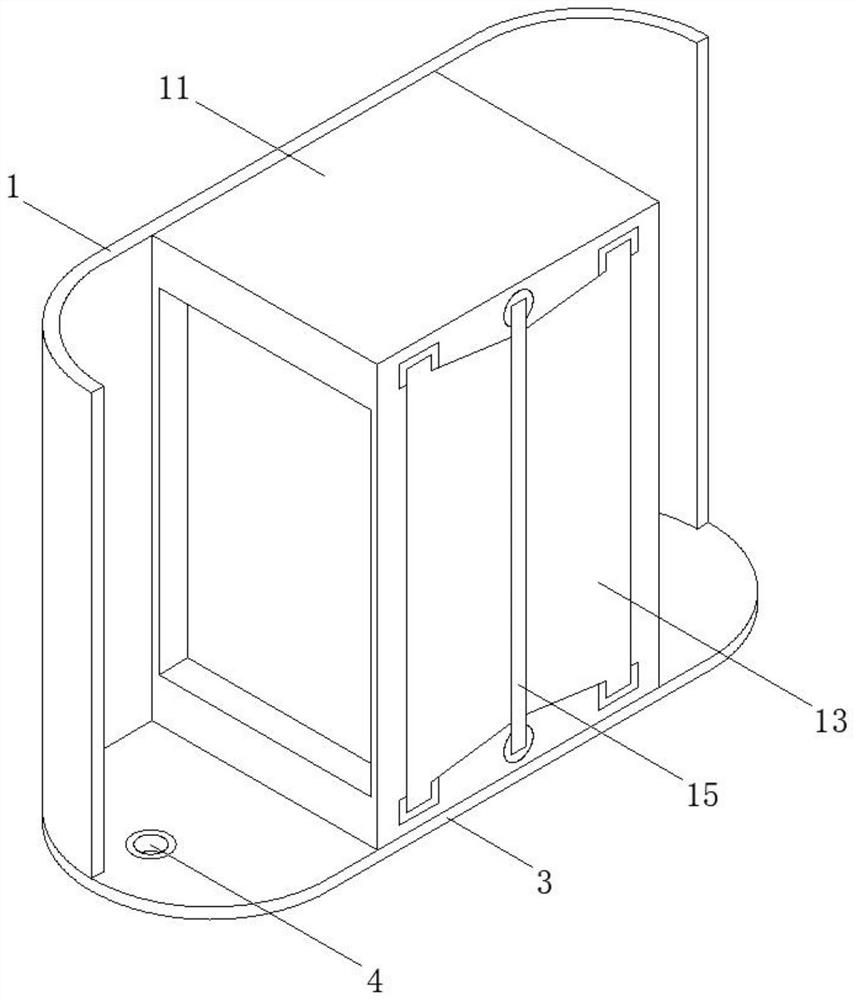

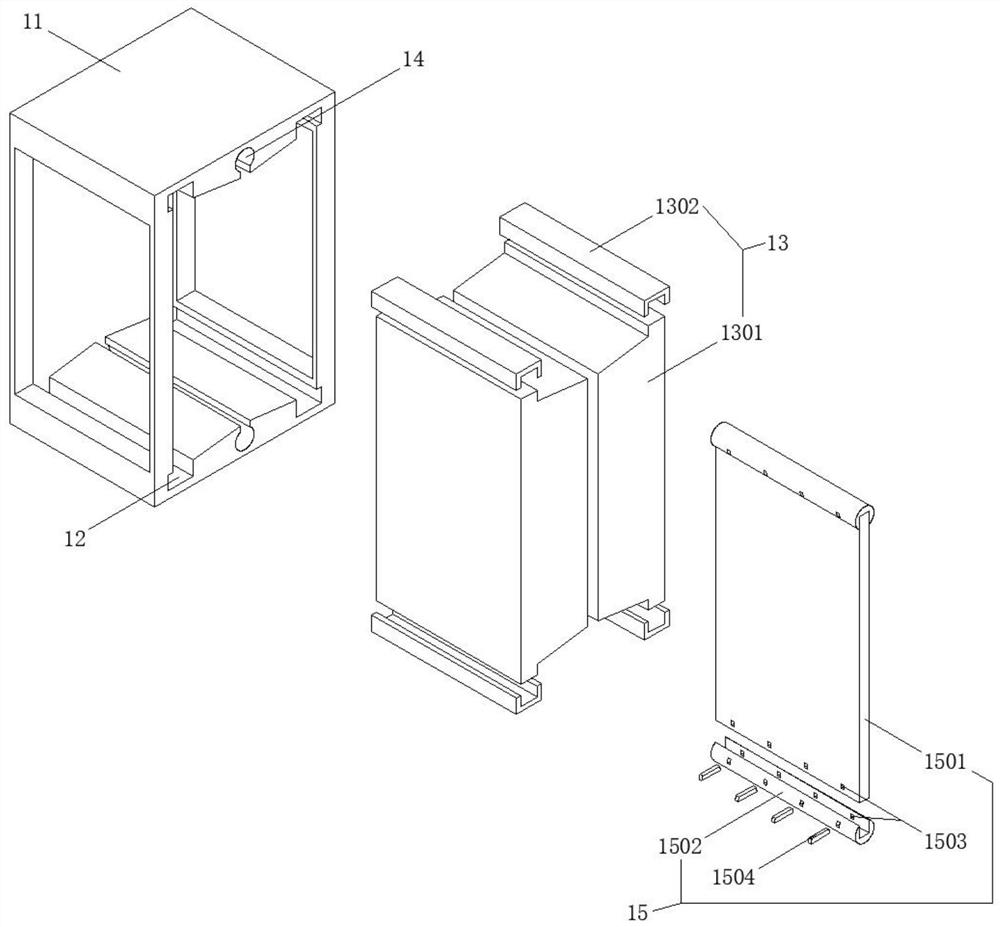

[0026] see Figure 1~5 , in an embodiment of the present invention, a proton exchange membrane cell structure for a hydrogen fuel cell, including a battery case 1, an insulating bottom plate 3, an insulating top plate 5, a terminal post 10, an electrode assembly 13 and a membrane assembly 15, the battery case 1 Both outer walls of the battery case 2 are provided with connecting components 2, and the connecting components 2 include raised strips 201, grooves 202 and screws 203, the bottom end of the battery case 1 is fixed with an insulating bottom plate 3, and one side of the insulating bottom plate 3 is set There is a drainage port 4, and the top of the battery case 1 is fixed with an insulating top plate 5, and the two sides inside the insulating top plate 5 are respectively provided with a hydrogen injection port 6 and an oxygen injection port 7, and there is a gap between the oxygen injection port 7 and the drain port 4. Corresponding to each other, the center position ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com