An optical axis consistency adjustment device

A technology of adjustment device and consistency, applied in the direction of measurement device, optical radiation measurement, instrument, etc., can solve the problem of inconvenient adjustment and testing, and achieve the effect of reducing the problem of inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

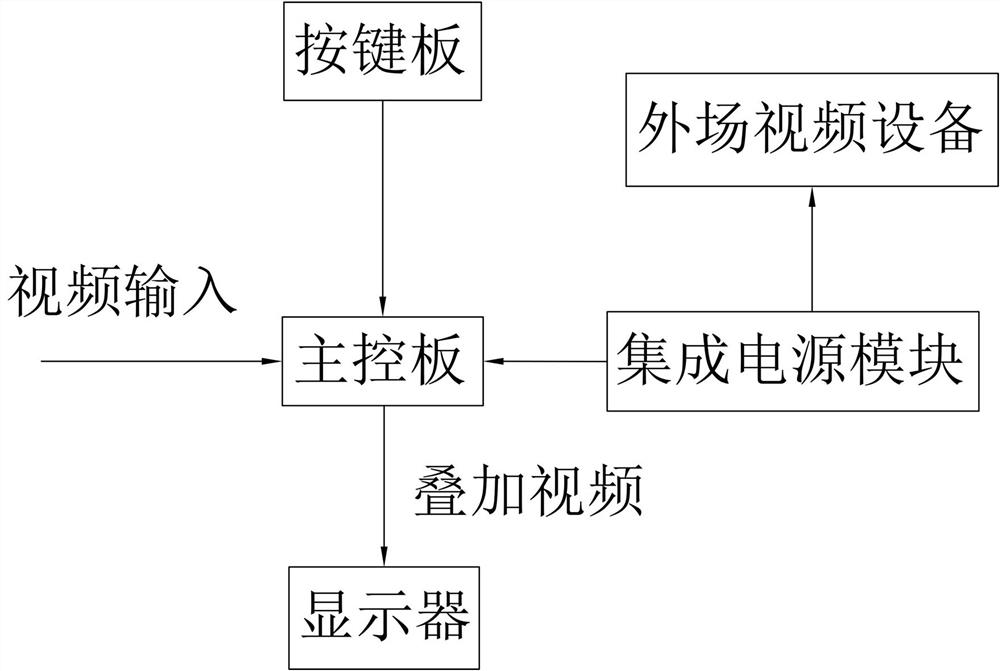

[0018] The optical axis adjustment device of this embodiment is mainly composed of an independent power supply, a main control board, a display, and a key board;

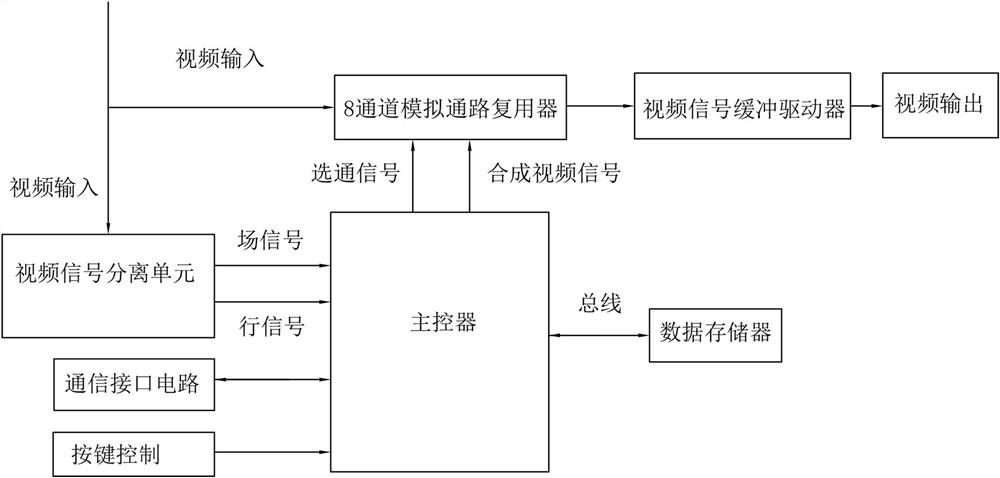

[0019] to combine figure 1 and figure 2 as shown,

[0020] The independent power supply is used to power the infrared thermal imager, visible light components, laser emitting device and laser receiving device;

[0021] The display is used for intuitive observation and combined with the key board to adjust the consistency of the optical axis;

[0022] The main control board includes: video signal separation module, communication interface circuit, main controller, 8-channel analog multiplexer, video signal buffer driver, data memory; the main control board is used to process video signals, including infrared heat Imager, visible light components, and laser receiving device for imaging signal processing;

[0023] The video signal separation module described herein separates the video signals received by the infra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com