Metal saw blade and preparation method thereof

A saw blade and metal technology, applied in the field of metal saw blade and its preparation, can solve the problems of general toughness, stability and strength, easy deviation of external handle connection, easy breakage of metal saw blade, etc., to save materials, improve strength and plasticity , easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

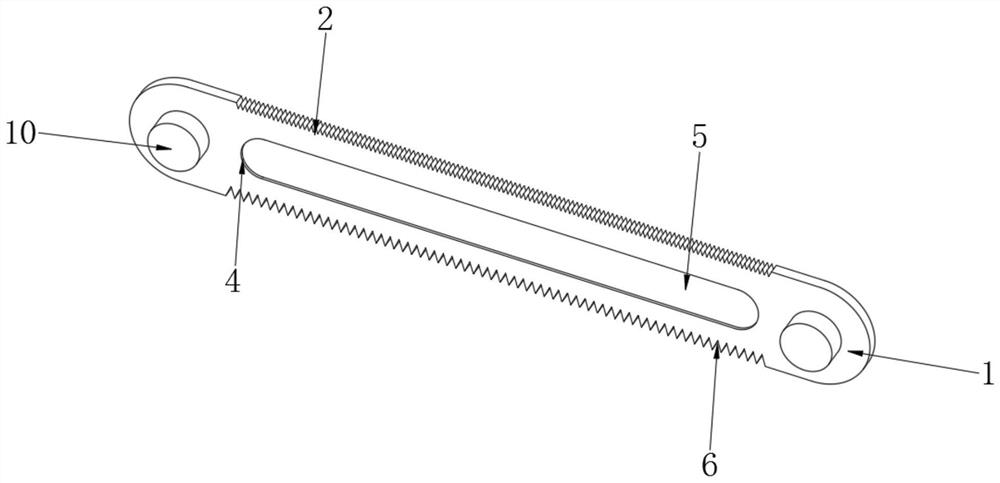

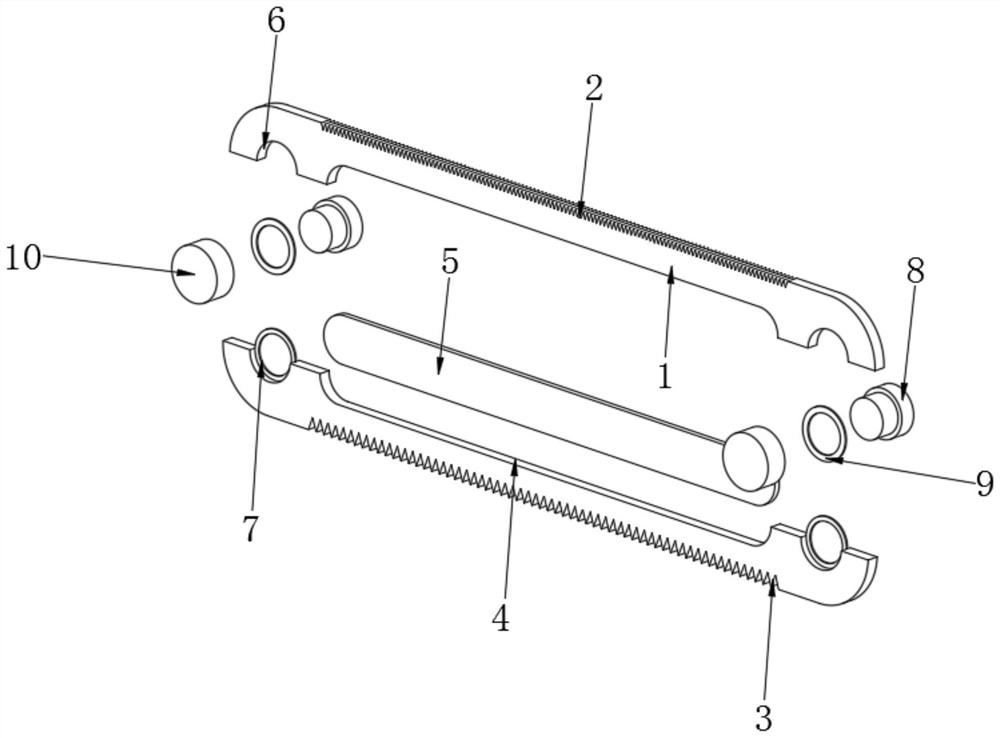

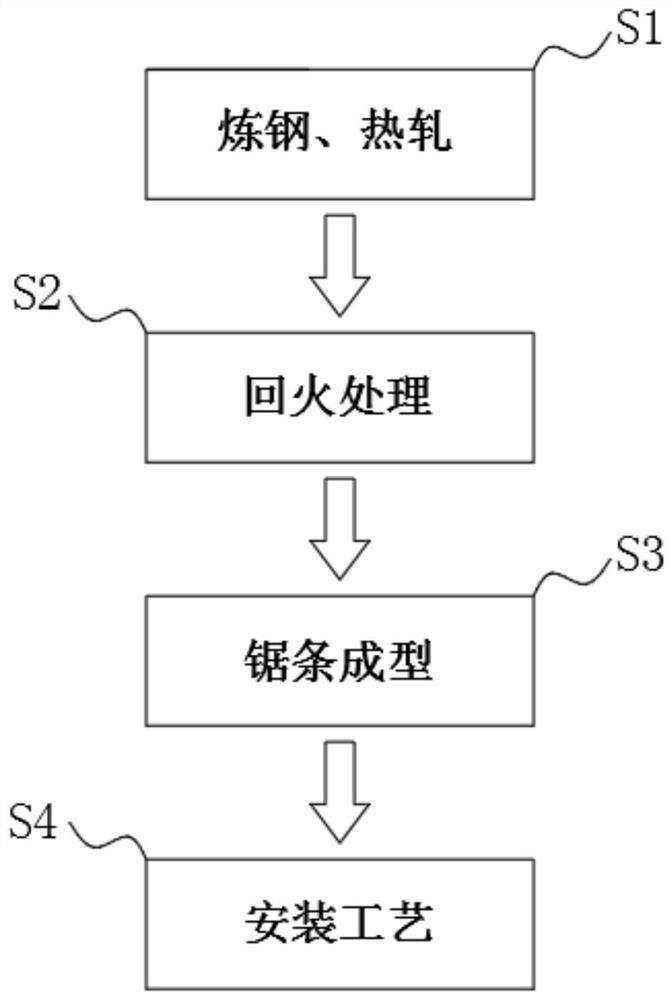

[0030] A metal saw blade, comprising a saw blade main body 1 and saw teeth arranged on the saw blade main body 1, the saw teeth include first saw teeth 2 arranged on the top of the saw blade main body 1 and second saw teeth 3 arranged on the bottom of the saw blade main body 1, the first saw teeth 2 and The second sawtooth 3 is integrally formed with the saw blade main body 1 by stamping process, and the tooth spacing of the first sawtooth 2 and the second sawtooth 3 are different. The middle position of the saw blade main body 1 is provided with a through groove 4, and the inside of the through groove 4 is embedded. The cemented carbide plate 5 is fixed in the form, and the two sides of the surface of the saw blade main body 1 are provided with installation mechanisms.

[0031] Preferably, both the first sawtooth 2 and the second sawtooth 3 include a tooth tip and a tooth root, the hardness of the tooth tip is greater than that of the tooth root, and the ratio of the height of...

Embodiment 2

[0040]A metal saw blade, comprising a saw blade main body 1 and saw teeth arranged on the saw blade main body 1, the saw teeth include first saw teeth 2 arranged on the top of the saw blade main body 1 and second saw teeth 3 arranged on the bottom of the saw blade main body 1, the first saw teeth 2 and The second sawtooth 3 is integrally formed with the saw blade main body 1 by stamping process, and the tooth spacing of the first sawtooth 2 and the second sawtooth 3 are different. The middle position of the saw blade main body 1 is provided with a through groove 4, and the inside of the through groove 4 is embedded. The cemented carbide plate 5 is fixed in the form, and the two sides of the surface of the saw blade main body 1 are provided with mounting mechanisms.

[0041] Preferably, both the first sawtooth 2 and the second sawtooth 3 include a tooth tip and a tooth root, the hardness of the tooth tip is greater than that of the tooth root, and the ratio of the height of the ...

Embodiment 3

[0050] A metal saw blade, comprising a saw blade main body 1 and saw teeth arranged on the saw blade main body 1, the saw teeth include first saw teeth 2 arranged on the top of the saw blade main body 1 and second saw teeth 3 arranged on the bottom of the saw blade main body 1, the first saw teeth 2 and The second sawtooth 3 is integrally formed with the saw blade main body 1 by stamping process, and the tooth spacing of the first sawtooth 2 and the second sawtooth 3 are different. The middle position of the saw blade main body 1 is provided with a through groove 4, and the inside of the through groove 4 is embedded. The cemented carbide plate 5 is fixed in the form, and the two sides of the surface of the saw blade main body 1 are provided with mounting mechanisms.

[0051] Preferably, both the first sawtooth 2 and the second sawtooth 3 include a tooth tip and a tooth root, the hardness of the tooth tip is greater than that of the tooth root, and the ratio of the height of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap