Process parameter optimization method for bio-ink 3D printing of planar solid graph

A technology of process parameter optimization and 3D printing, applied in processing data acquisition/processing, additive processing, manufacturing auxiliary devices, etc. Optimize, ensure data reliability, and facilitate the effect of operation and settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

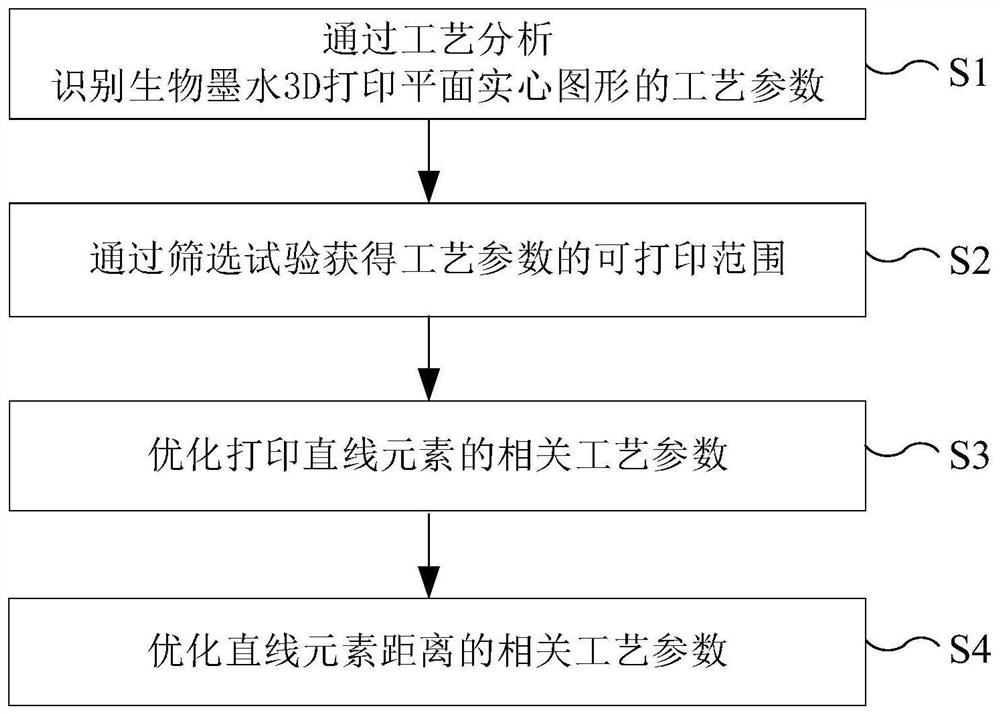

[0094] Such as figure 1 As shown, the process parameter optimization method of the bio-ink 3D printing plane solid figure, the steps are as follows:

[0095] S1. By analyzing the 3D printing process, determine the process parameters of the bio-ink 3D printing plane solid figure; specifically, the specific operation of this step S1 is as follows:

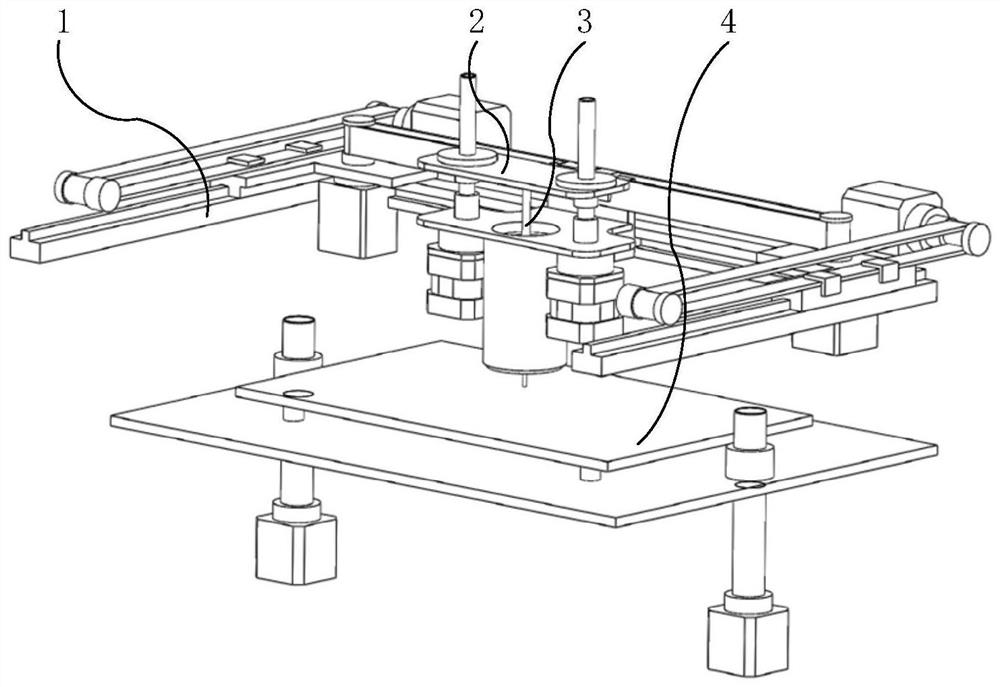

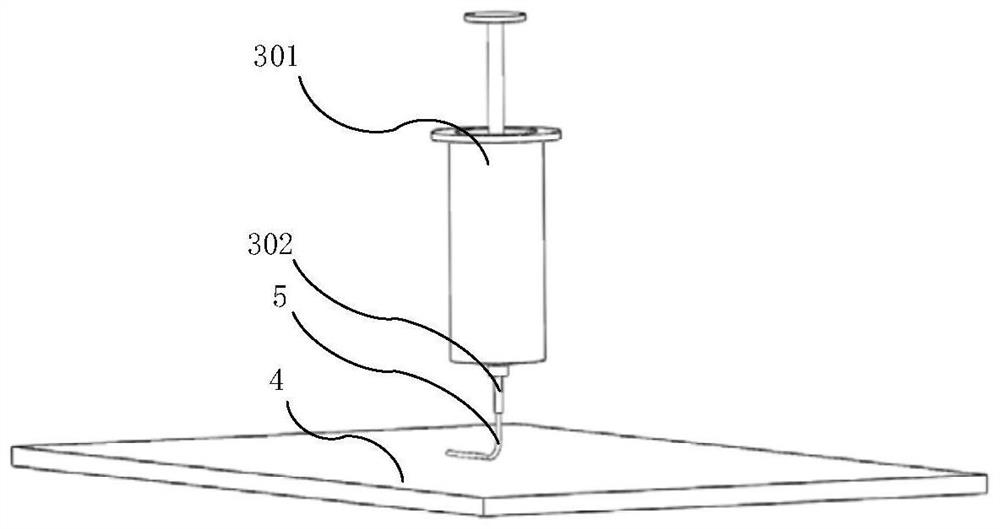

[0096] use as figure 2 The extrusion type 3D printer shown carries out the planar solid pattern printing of bio-ink; Wherein, as figure 2 and image 3 As shown, the extrusion 3D printer includes: a three-axis motion platform 1, a piston 2, an extrusion device 3, a substrate 4 and a bioink 5; the extrusion device 3 includes a needle tube 301 and a nozzle 302;

[0097] The technological process of 3D printing a flat solid figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com