Carbon fiber composite material automobile rear top cross beam assembly structure

A composite material and assembly structure technology, applied in the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problems of rigidity, strength performance difficult to meet requirements, practicability and comfort, and easy to rust, etc. Achieve the effect of solving manufacturing complexity, reducing equipment investment, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

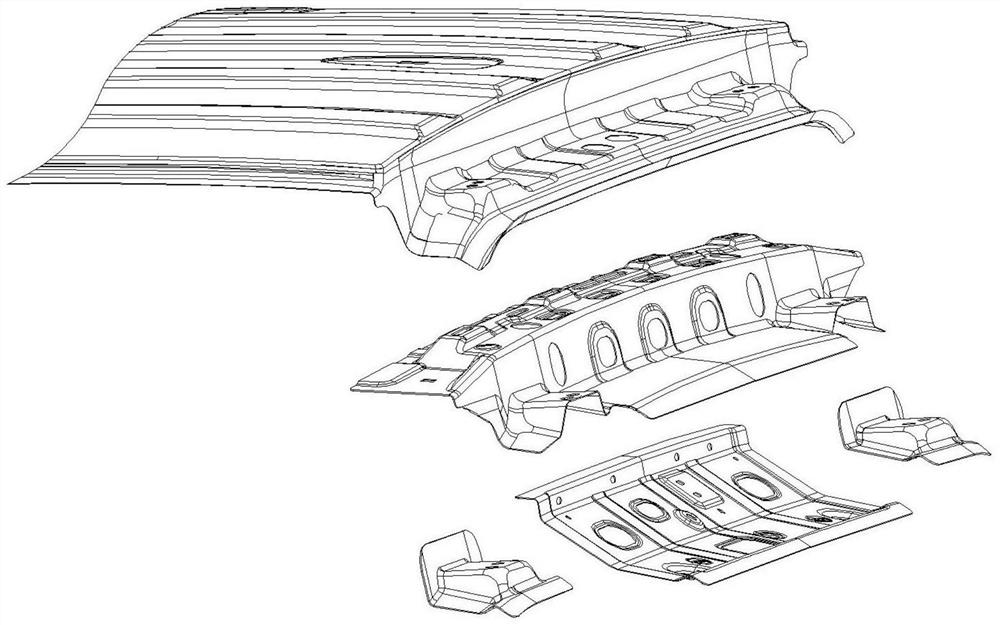

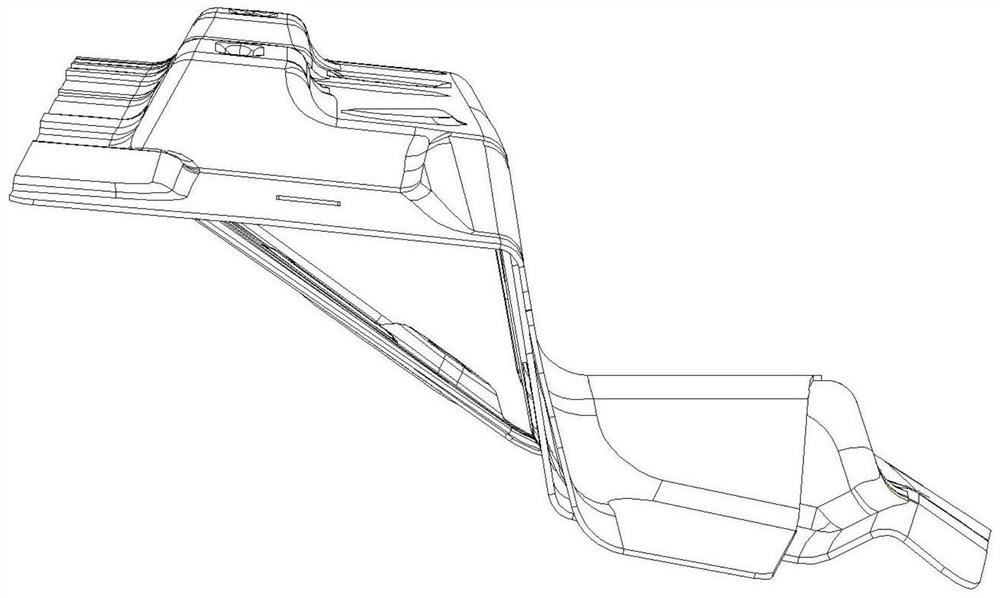

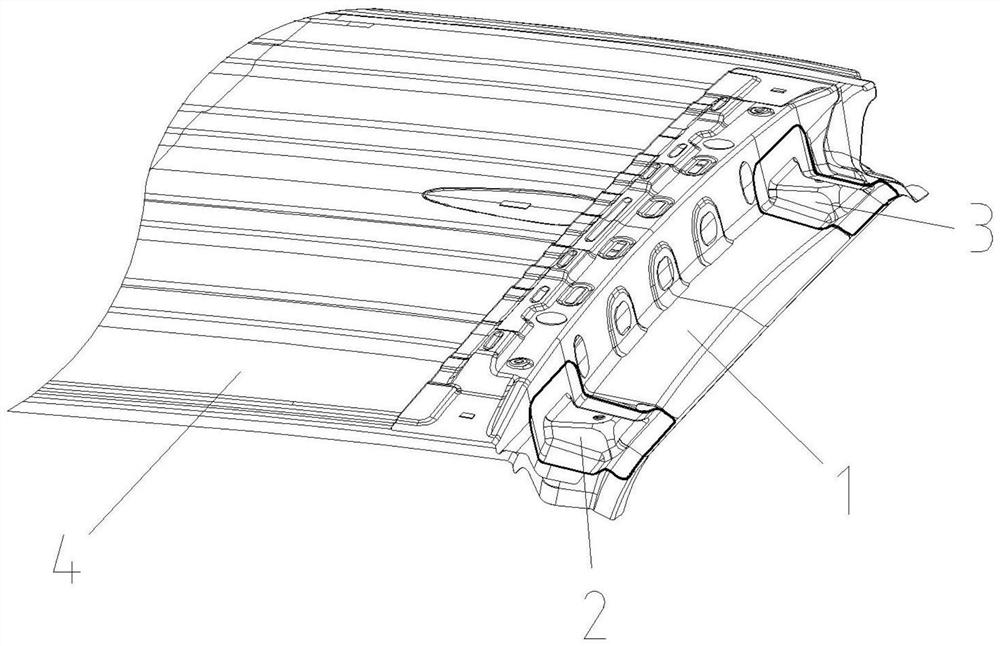

[0027] Such as Figure 3 to Figure 7 Shown is a carbon fiber composite automobile rear roof beam assembly structure, the automobile rear roof beam assembly is only composed of the rear roof beam body 1, the back door left hinge reinforcement plate 2 and the back door right hinge reinforcement plate 3, without other redundant parts; the rear roof beam body 1 is fixedly connected to the lower end surface of the vehicle roof 5, and the rear door left hinge reinforcement plate 2 and the rear door right hinge reinforcement plate 3 are fixedly connected to the rear roof beam body 1 End face; the rear top beam body 1, the left hinge reinforcement plate 2 of the back door and the right hinge reinforcement plate 3 of the back door are all carbon fiber composite materials, and the carbon fiber composite material only needs a thickness of 1.5 mm to meet the strength and rigidity requirements.

[0028] Further, in order to better cooperate and connect the rear roof beam body 1, the left h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com