Fabricated steel structure spiral stair

A technology for rotating stairs and steel structures, applied in stairs, stepped structures, building structures, etc., can solve the problems of complex procedures and long construction periods, and achieve the effects of good structural strength, reduced construction difficulty, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

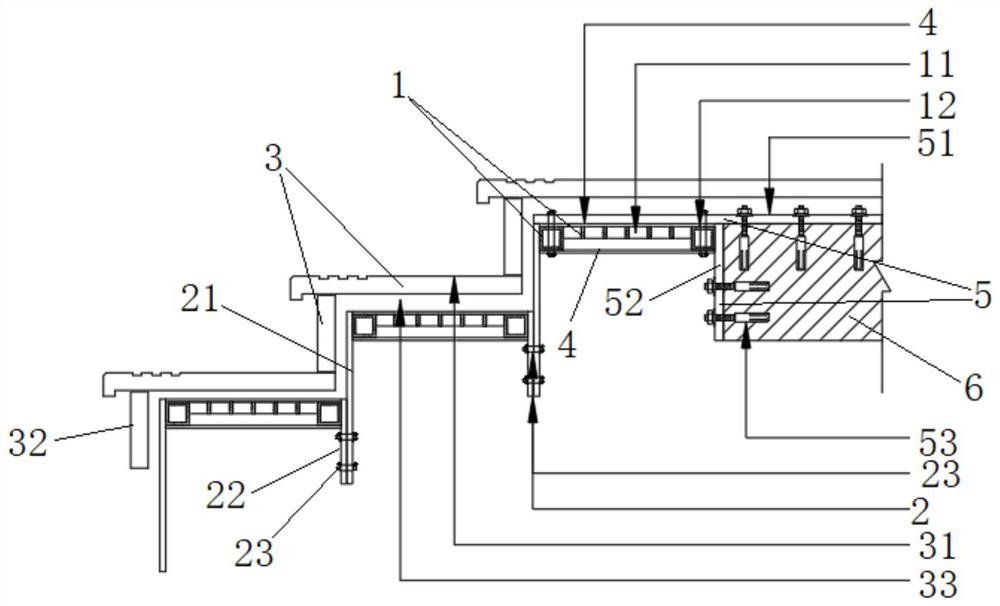

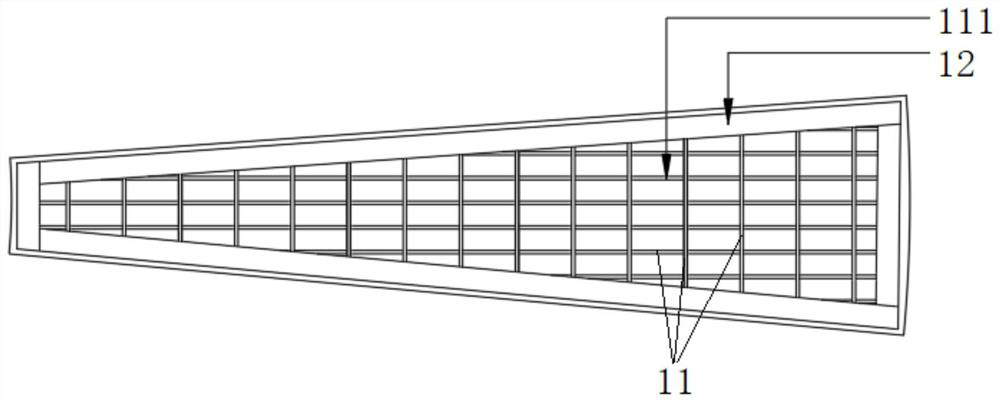

[0034] see figure 1 , the figure shows a prefabricated steel structure spiral staircase provided by Embodiment 1 of the present invention, which includes a plurality of step units arranged and connected sequentially from top to bottom, a plurality of step units rotate and distribute, and the step units The unit includes: a supporting assembly 1, which includes a steel grid 11 and a connecting frame 12 arranged on the outer periphery of the steel grid 11; a connecting assembly 2, which includes a first connecting plate 21 and a second connecting plate 22, the first The connecting plate 21 and the second connecting plate 22 are respectively arranged on both sides of the support assembly 1 along the vertical direction, and the height of the first connecting plate 21 is greater than that of the second connecting plate 22, and the second connecting plate 22 is The connecting plate 22 is located inside the support assembly 1; the decorative panel 3 includes a plane plate 31 and a ve...

Embodiment 2

[0043] see Figure 1-2 , the figure shows a prefabricated steel structure spiral staircase provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: steel grating 11 and the top and bottom of the connecting frame 12 are provided with a reinforcement plate 4, the thickness of the reinforcing plate 4 is 5mm; the connecting frame 12 is a connecting pipe, and the connecting pipe is a hot-dip galvanized square pipe; It includes a plurality of vertically connected steel pipes 111, and the specification of the steel pipes 111 is 20mm. Through the arrangement of the above structure, the strength of the steel grid 11 itself can be improved, and the connection strength between the steel grid 11 and the connecting frame 12 can be improved at the same time.

Embodiment 3

[0045] see figure 1 , the figure shows a prefabricated steel structure spiral staircase provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The step unit also includes a "T"-shaped fixed plate 5; the fixed plate 5 includes a horizontal plate 51 and a vertical plate 52, the horizontal plate 51 is located on the upper surface of the support assembly 1, and the vertical plate 52 is located on The inner side of the support assembly 1, and the horizontal plate 51 and the vertical plate 52 are connected to the building base 6; the horizontal plate 51 and the vertical plate 52 are connected to the first fastener 53 The building bases 6 are connected, and the first fastener 53 is a chemical bolt; the thickness of the horizontal plate 51 and the vertical plate 52 is 15 mm. Through the setting of the above-mentioned structure and the setting of the fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com