Extra-long tunnel gushing water treatment method

A treatment method and tunnel technology, which is applied in tunnels, tunnel linings, ventilation of mines/tunnels, etc., to achieve the effects of reducing construction costs, solving high-pressure water gushing problems, and saving construction period costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

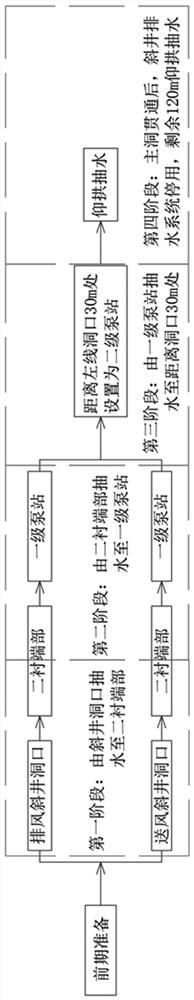

Method used

Image

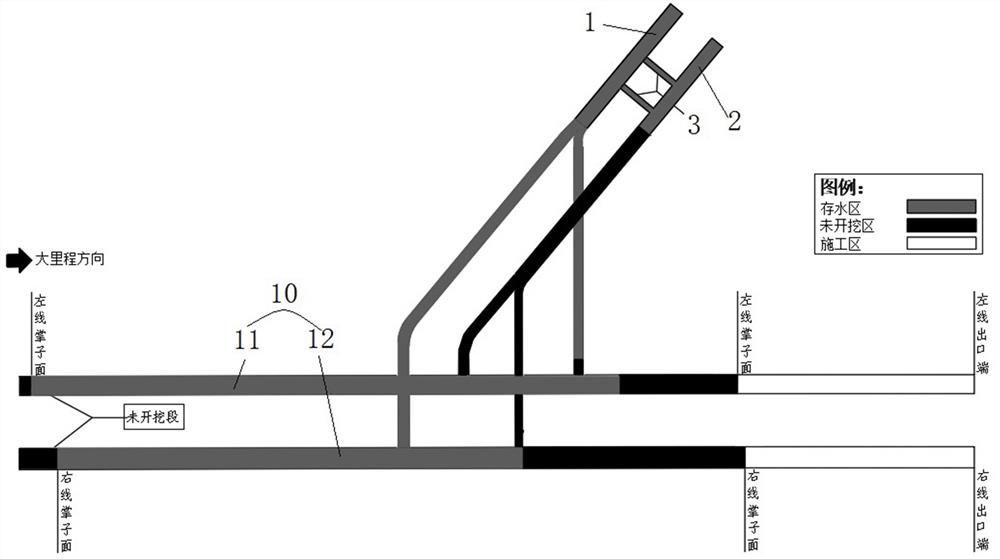

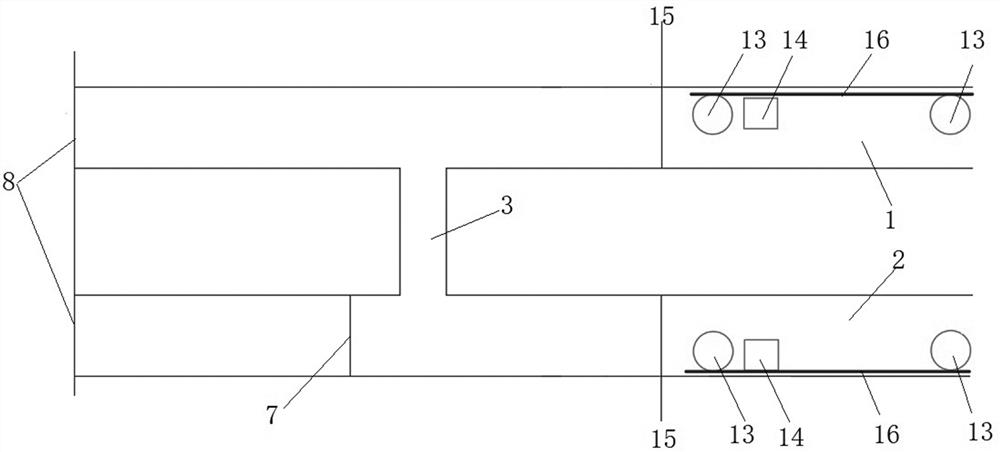

Examples

Embodiment Construction

[0038] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings and specific embodiments. Obviously, the described embodiments are only the present invention. Some examples, but not all examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0039] As we all know, small and medium-sized karst caves in karst landforms have a high degree of development, high content of karst water and fissure water, and the karst fissures in the mountain form a vertical vein. , poor bonding between rock layers. The excavation of the inclined shaft of the tunnel will greatly break the surrounding rock, the dissolution cavity and the groove will be cut, and high head pressure will be formed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com