Equivalent icing thickness monitoring method based on accurate measurement of conductor sag change

A technology of icing thickness and wire sag, which is applied to measuring devices, instruments, alarms, etc., can solve the problems of failure to achieve stable icing and accurate online monitoring of transmission lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

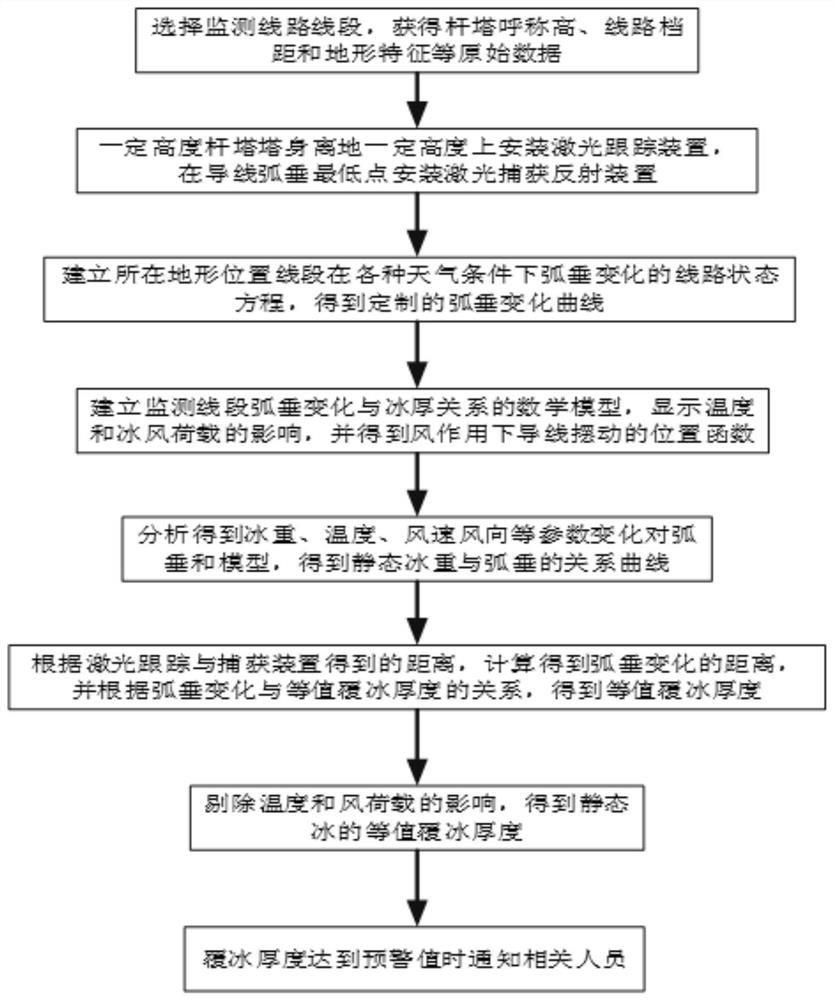

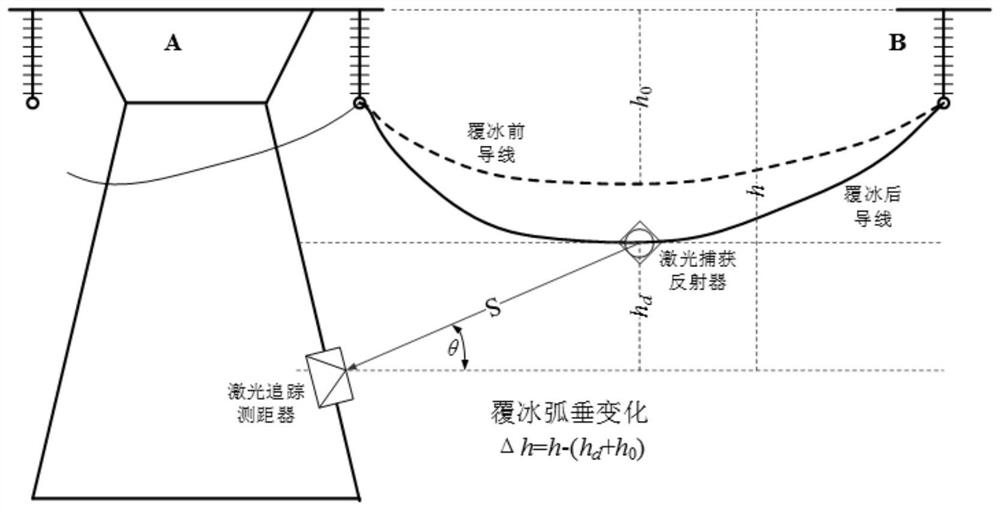

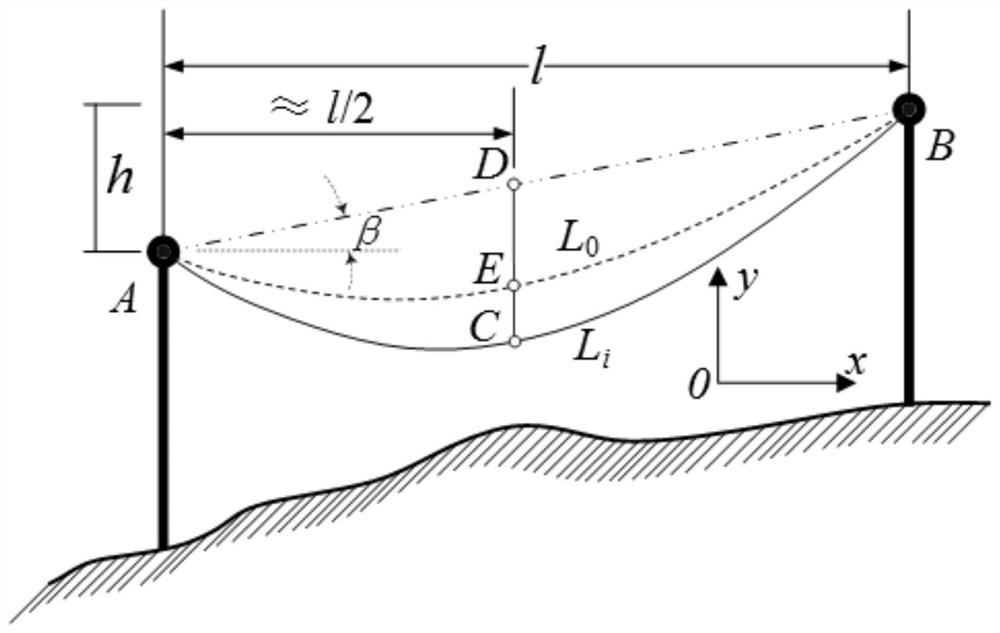

[0037] Below in conjunction with accompanying drawing, the present invention is described in further detail, as shown in the figure:

[0038] The present invention provides a method for monitoring the equivalent ice thickness based on wire sag changes, comprising the following steps:

[0039] Select a span section of the transmission line to be monitored in areas with severe icing, and obtain the original data such as tower height, line span and terrain characteristics, determine the ground base point corresponding to the lowest sag, and obtain the online monitoring of wire icing Location information and basic information.

[0040] Specifically, an equivalent ice thickness monitoring method based on the accurate measurement of conductor sag changes proposed by the present invention can be applied to a representative section of a transmission line in a severely ill area or a designated line segment that needs to be monitored, so as to reflect the power transmission in a local a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com