Reflection-type concave conical mirror panoramic camera device suitable for deep hole observation of rock mass structure

A panoramic camera and reflective technology, applied in the direction of measuring devices, installation, photography, etc., can solve compatibility problems, not suitable for deep hole testing work, not satisfying the principles of metrology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

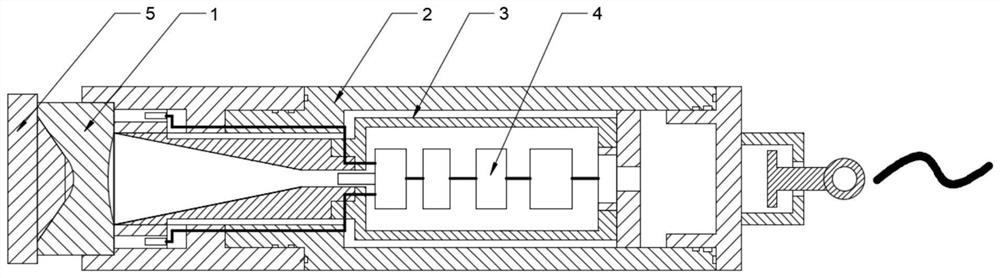

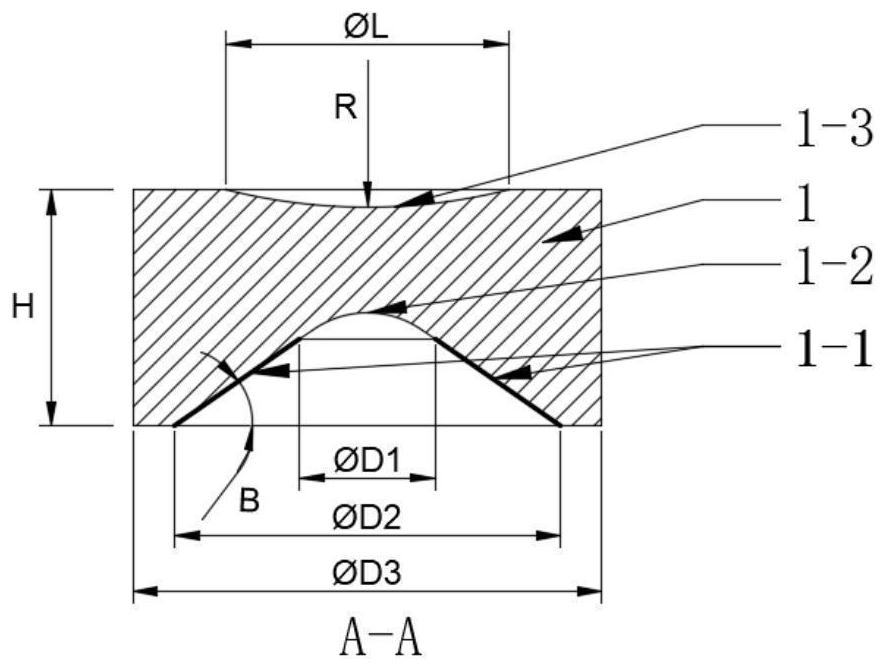

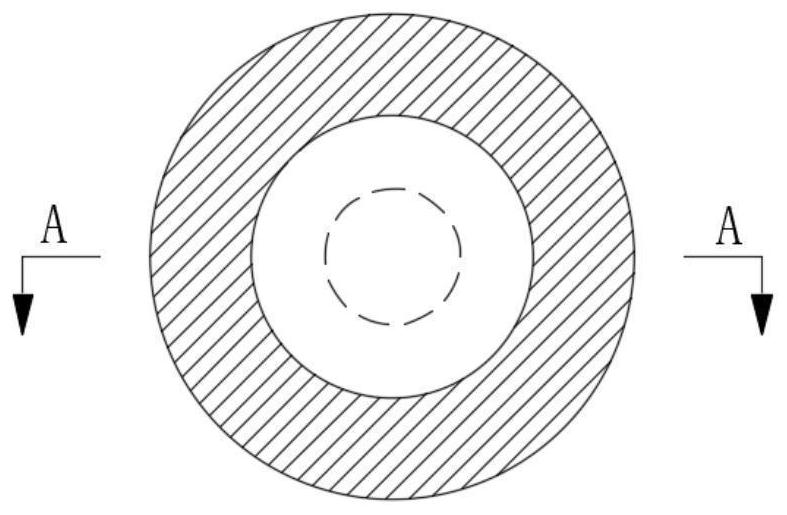

[0052] Embodiment 1 provided by the present invention is an embodiment of a reflective concave-cone mirror panoramic camera device suitable for observing rock mass structures in deep holes provided by the present invention. figure 1 It can be seen that the panoramic camera device includes the following five static mechanical structures: a reflective concave cone mirror 1, a metal shell 2, a fixed frame 3, a data acquisition circuit 4, and a buffer protection component 5. After assembling the five static mechanical structures, Together they constitute a reflective concave-cone mirror panoramic camera device.

[0053] The metal shell 2 is in the shape of a hollow cylinder, and the reflective concave conical mirror 1 is connected to an open end of the metal shell 2, figure 1 In the given embodiment, the right end of the reflective concave-conical mirror 1 is connected to the left end of the glass window connector 2-1 of the metal housing 2, which can be bonded by glue. The data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com