Laundry detergent

A laundry detergent and surfactant technology, applied in the direction of detergent compounding agent, detergent composition, surface active detergent composition, etc., can solve the problems of reducing the aesthetic value of fabrics, yellowing, etc., and achieve the promotion of cationic interaction , increase long-term existence, reduce interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] Preparation of hueing dyes

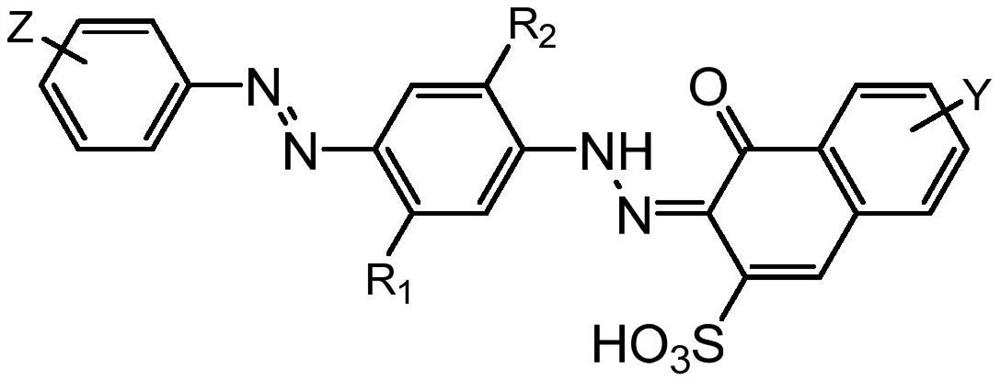

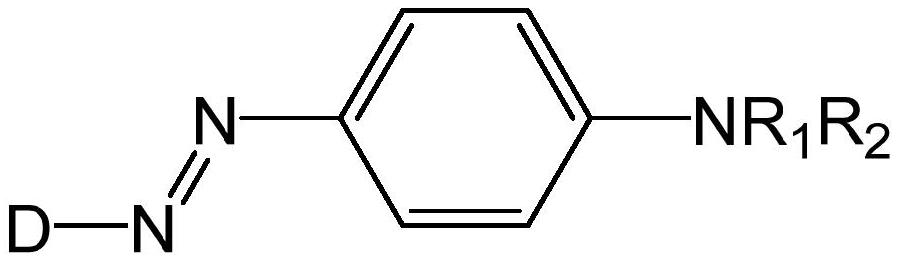

[0070] Disazo dyes can be synthesized via well-known azo coupling reactions, such as

[0071]

[0072] in for

[0073] WO2012 / 054058 describes having at least one 2 Synthesis of various disazo dyes with CHO group-terminated polyalkoxy chains.

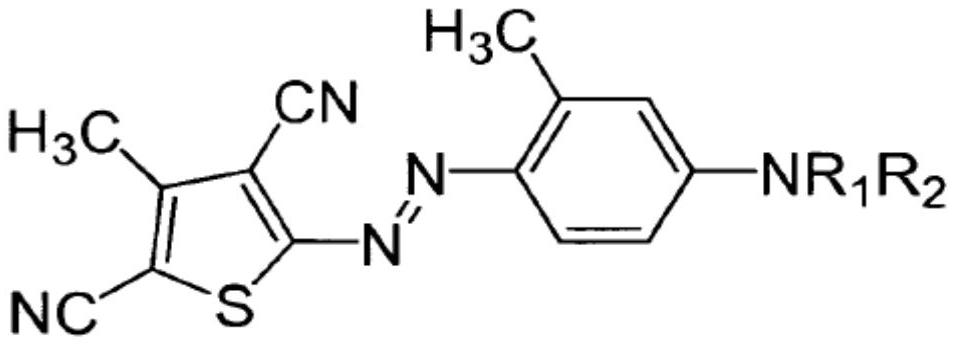

[0074] The synthesis of alkoxylated monoazothiophene dyes is described in US4912203 and WO2011 / 017719. The main coupling reactions are:

[0075]

[0076] where R 1 and / or R 2 is an alkoxylated moiety.

[0077] pass-ch 2 Capping by CHO moieties can be obtained by (partial) oxidation of the corresponding alkoxylated material as follows:

[0078]

[0079] Usually, the -CH 2 CH 2 OH is partially oxidized to -CH 2 The CHO moiety can be achieved by using acidified sodium dichromate, preferably followed by purification of the resulting hueing dye according to the invention.

[0080] Usually, at least one alkoxy-CH 2 CHO or -CH 2 Covalent attachment of CHO-terminated polyalkoxy gr...

Embodiment 1

[0141] Liquid laundry detergents can be prepared with the following formulations:

[0142]

[0143] The liquid laundry detergent contained 0.001% by weight of a hueing dye according to the structure (Example 1, according to the invention):

[0144]

[0145] where r=1 and q is 1 (ie, r+q=2) (Example 1). As a comparative example (not according to the invention), 0.001% by weight of the same structure, but in which -CH 2 The CHO group is replaced by -CH 2 CH 2 OH-substituted shading dye (Comparative Example A, not according to the invention). As a reference, this liquid laundry detergent composition was used without any added hueing dye (reference liquid).

[0146] The wash liquor is prepared by dosing 4 g / L of laundry detergent powder into 13°FH water in a Tergotometer tank and adding a 10 x 10 cm piece of textile cotton, knitted cotton, 65 / 35 polycotton, microfiber polyester Or 80 / 20 Nylon-Elastane fabric for a 100:1 wash liquor to fabric ratio. The wash solution wa...

Embodiment 2

[0149] A powder laundry detergent formulation can be prepared having the following formulation:

[0150]

[0151]

[0152] The shading dye particles are as described in WO2006 / 053598, the formulation containing 0.0004% by weight of shading dye. The hueing dye is according to the following structure (ie Example 2, according to the invention).

[0153]

[0154] where r=1 and q is 1 (ie, r+q=2) (Example 2). As a comparative example (not according to the invention), 0.001% by weight of the same structure, but in which -CH 2 The CHO group is replaced by -CH 2 CH 2 OH-substituted shading dye (Comparative Example B, not according to the invention). As a reference, a powder laundry detergent composition was used without any added hueing dye (reference powder).

[0155] The wash solution is prepared by dosing 4 g / L of laundry detergent powder into 13°FH water in a Tergotometer tank and adding a 10 x 10 cm piece of textile cotton, knitted cotton, 65 / 35 polycotton, microfib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com