Laundry detergent

A technology of laundry detergent and surfactant, applied in the field of laundry detergent composition, can solve the problems of reducing the aesthetic value of fabrics, yellowing, etc., and achieve the effects of improving hydrolysis resistance, improving reactivity, and improving directness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

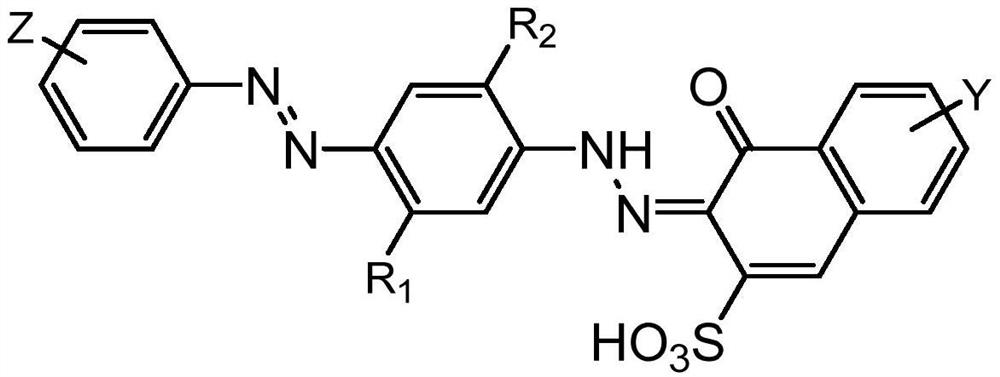

[0066] Preparation of blue or violet azo dyes

[0067] Preferred disazo dyes can be synthesized via well-known azo coupling reactions, such as

[0068]

[0069] in for

[0070] WO2012 / 054058 describes having at least one -CH=CH 2 Synthesis of various disazo dyes of group-terminated polyalkoxy chains, although such dyes also contain additional -COOH groups.

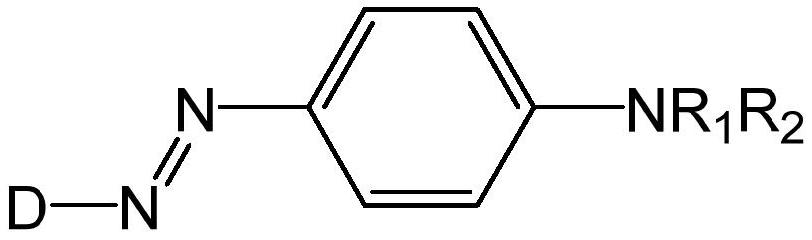

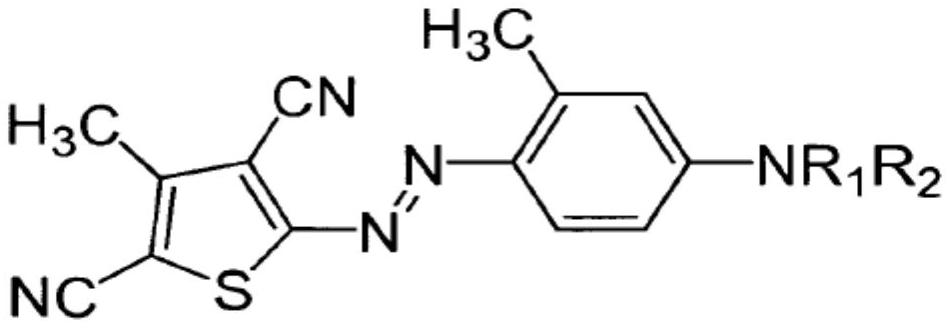

[0071] The synthesis of monoazothiophene dyes is described in US4912203 and WO2011 / 017719. The main coupling reactions are:

[0072]

[0073] where R 1 and R 2 At least one of them represents alkoxy-CH=CH 2 or -CH=CH 2 Capped polyalkoxy groups.

[0074] -CH=CH 2 Parts can be obtained by dehydrating the corresponding ethoxylated material as follows:

[0075]

[0076] and

[0077]

[0078] Dehydration of terminal alcohol groups can be achieved by heating in the presence of a strong acid such as sulfuric or phosphoric acid, followed by purification.

[0079] Additional advantages of the shading d...

Embodiment 1

[0140] Liquid laundry detergents can be prepared with the following formulations:

[0141]

[0142] The liquid laundry detergent contained 0.001% by weight of a hueing dye according to the structure (Example 1, according to the invention):

[0143]

[0144] where r=1 and q is 1 (ie, r+q=2) (Example 1). As a comparative example (not according to the invention), 0.001% by weight of a hueing dye with the following structure can be used:

[0145]

Embodiment 2

[0150] A powder laundry detergent formulation can be prepared having the following formulation:

[0151] Element weight% linear alkylbenzene sulfonate 14.5 Sodium carbonate 20.0 sodium sulfate 50.0 Sodium silicate 6.0 Zeolite 2.5 Salt Spot Granules (Blue and Red) 1.8 spices 0.3 Sodium carboxymethyl cellulose 0.1 Sokalan CP5 (from BASF) 0.1 Hue Dye Granules 0.3 Minor ingredients (including fluorescent agents) and moisture to 100%

[0152] The shading dye particles are as described in WO2006 / 053598, the formulation containing 0.0004% by weight of shading dye. The hueing dye is according to the following structure (ie Example 2, according to the invention).

[0153]

[0154] where r=1 and q is 1 (ie, r+q=2) (Example 2). As a comparative example (not according to the invention), 0.001% by weight of a hueing dye of the following structure can be used:

[0155]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com