Turnover type double-sided saline injection machine for meat pickling

A salt water injection machine and salt water injection technology, applied in the direction of meat softening, application, and meat tenderization through injection, can solve the problems of low salting efficiency, poor salting effect, waste of resources, etc., and achieve the effect of facilitating salt water injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

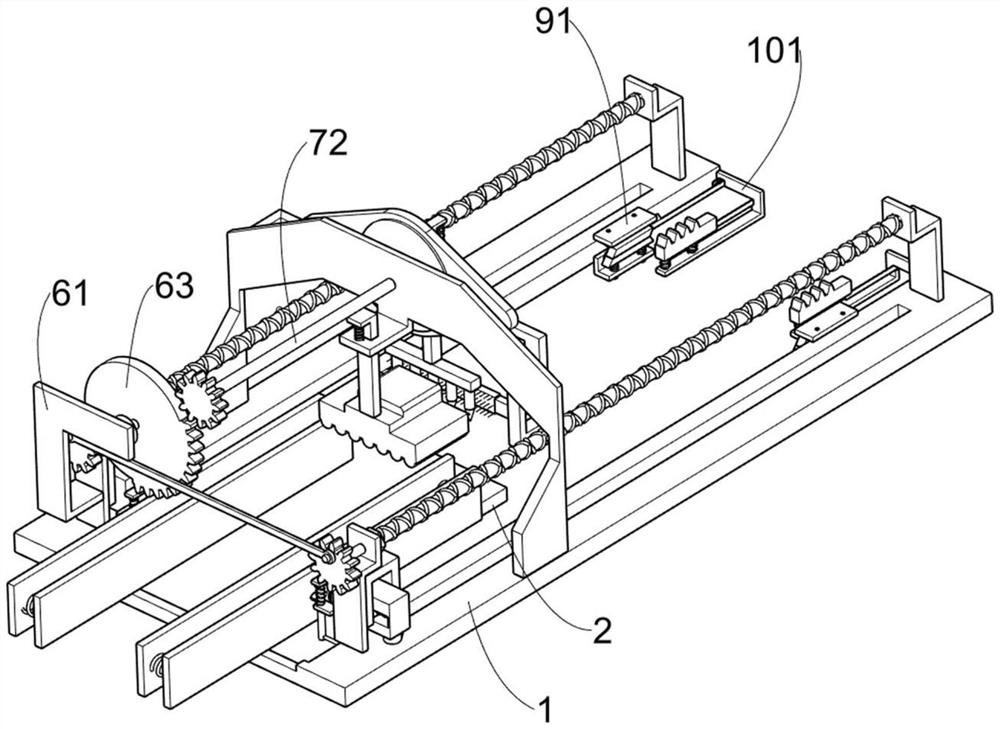

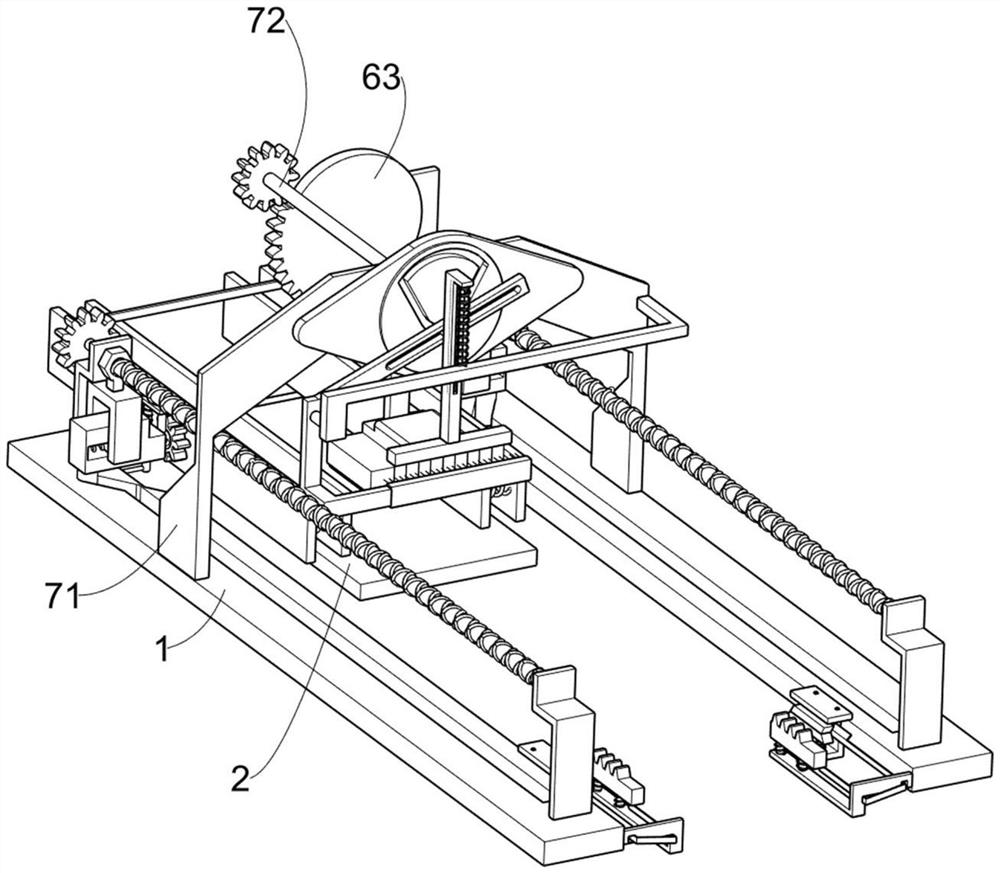

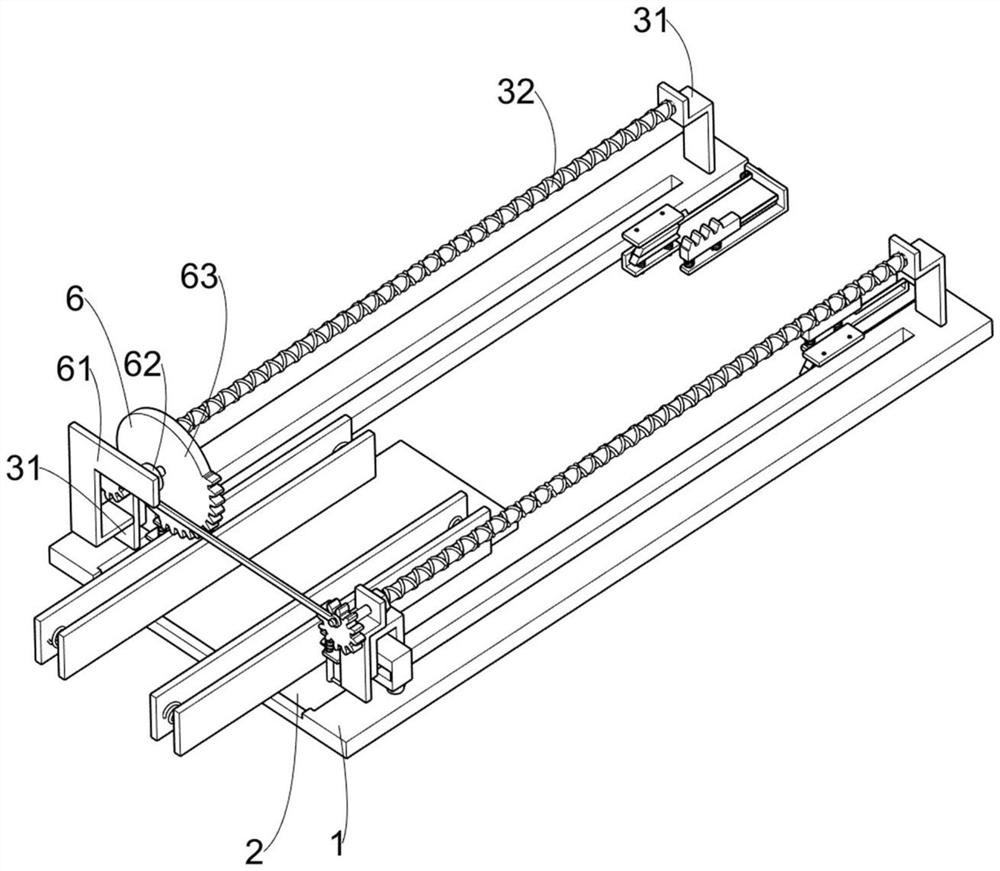

[0031] A flip-type double-sided brine injection machine for marinating meat, such as Figure 1-10 As shown, it includes a slotted guide plate 1, a first support plate 2, a clamping delivery assembly 3, a limit assembly 4, a drive assembly 6, a saline injection assembly 7, a kneading assembly 8, a one-way support assembly 9 and a turning assembly The noodle mechanism 10, the first support plate 2 is positioned on the slotted guide plate 1, the clamping and conveying assembly 3 is arranged on the slotting guide plate 1, and the clamping and conveying assembly 3 is used to clamp the meat on the first support plate 2 , the limit assembly 4 is arranged on the clamping and conveying assembly 3, the drive assembly 6 is arranged on the clamping and conveying assembly 3, the saline injection assembly 7 is arranged on the slotted guide plate 1, and the saline injection assembly 7 is used to fully inject the saline To the meat, the kneading and pressing assembly 8 is arranged on the sali...

Embodiment 2

[0044] On the basis of Example 1, such as Figure 6 As shown, a cleaning assembly 11 is also included. The cleaning assembly 11 is arranged on the saline injection assembly 7. The cleaning assembly 11 is used to remove the minced meat stuck on the injection frame 76. The cleaning assembly 11 includes a slotted swing plate 111 and a hair The brush plate 112 is rotatably connected with a slotted swing plate 111 on the guide rod 75, and the slotted swing plate 111 and its upper device are swung by the cooperation of the injection frame 76 and the slotted swing plate 111, and the slotted swing plate 111 and the injection Frame 76 limit fits, slotted swing plate 111 is connected with hairbrush plate 112, and hairbrush plate 112 is used for removing the minced meat that sticks on injection frame 76, and hairbrush plate 112 contacts with injection frame 76.

[0045] Since when the injection frame 76 injects salt water into the meat, some minced meat will be stuck on the injection fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com