A carbon monoxide treatment process

A carbon monoxide treatment process technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of low carbon monoxide removal efficiency, achieve the effect of reducing coke ratio and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

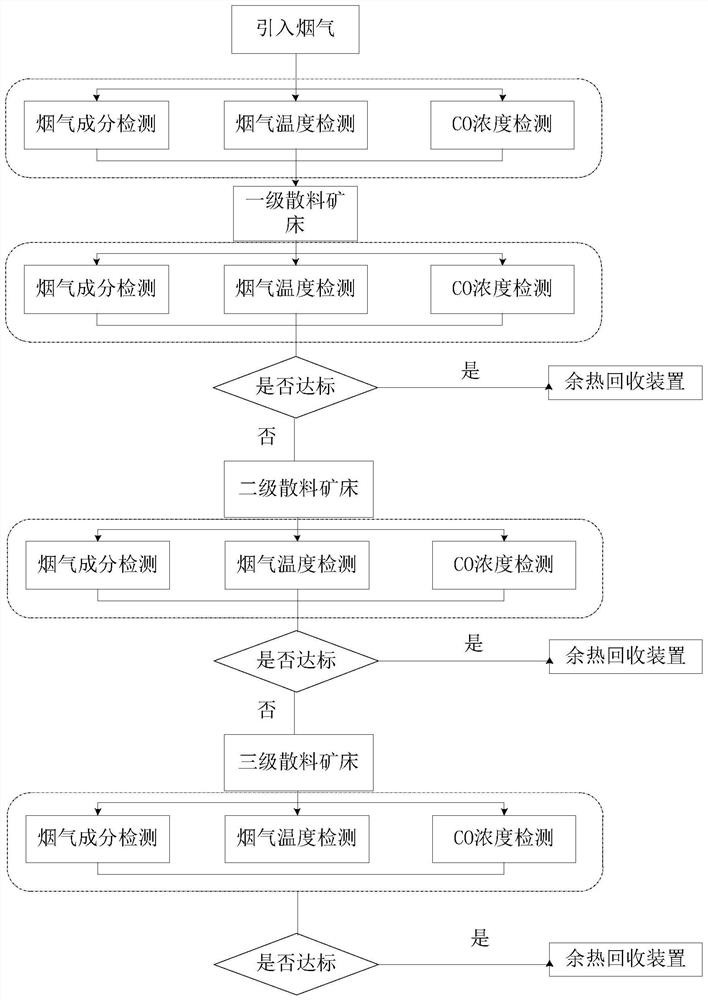

[0034] This embodiment provides a carbon monoxide treatment process, which is carried out on a reactor, and the reactor is provided with a bulk ore bed, and the bulk ore includes at least Fe 2 o 3 , the bulk ore bed comprises a first bulk ore bed;

[0035] Specifically, the reactor itself has a certain accommodation space, so as to realize the storage of bulk ore deposits. The reactor itself can be fixed or movable, and when the fixed setting is adopted, the equipment for introducing flue gas is also fixed. When the reactor itself is set in a mobile state, the equipment for introducing flue gas moves together with the reactor.

[0036] Described processing technology comprises the steps:

[0037] Judging the temperature of bulk ore deposits;

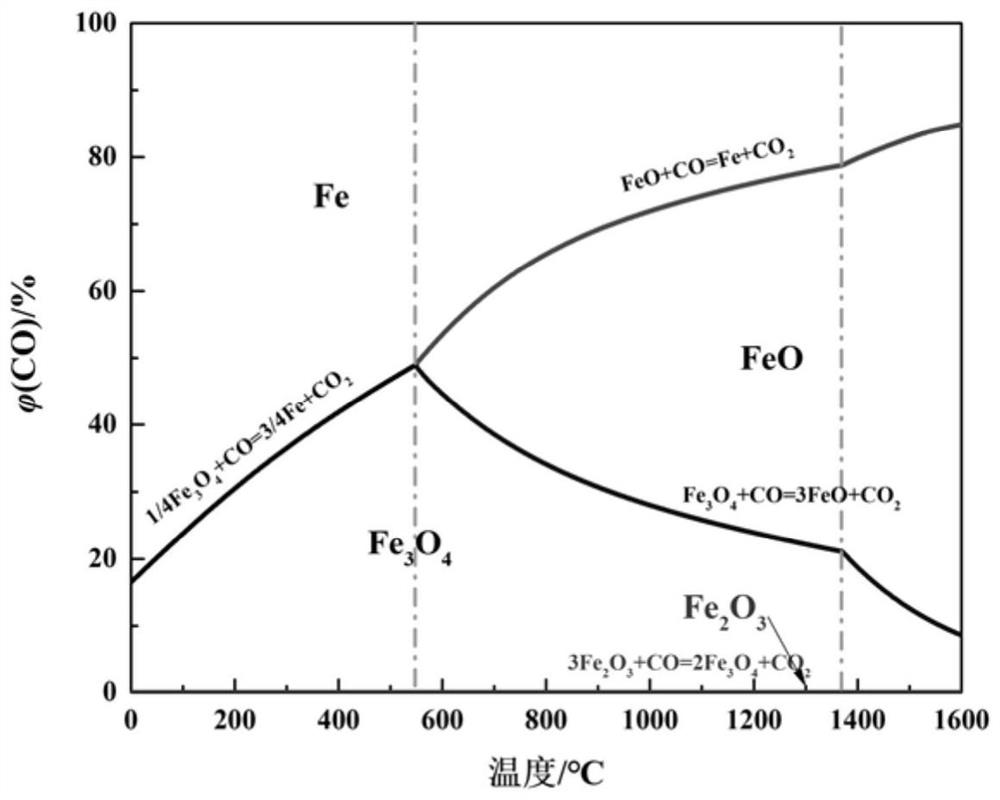

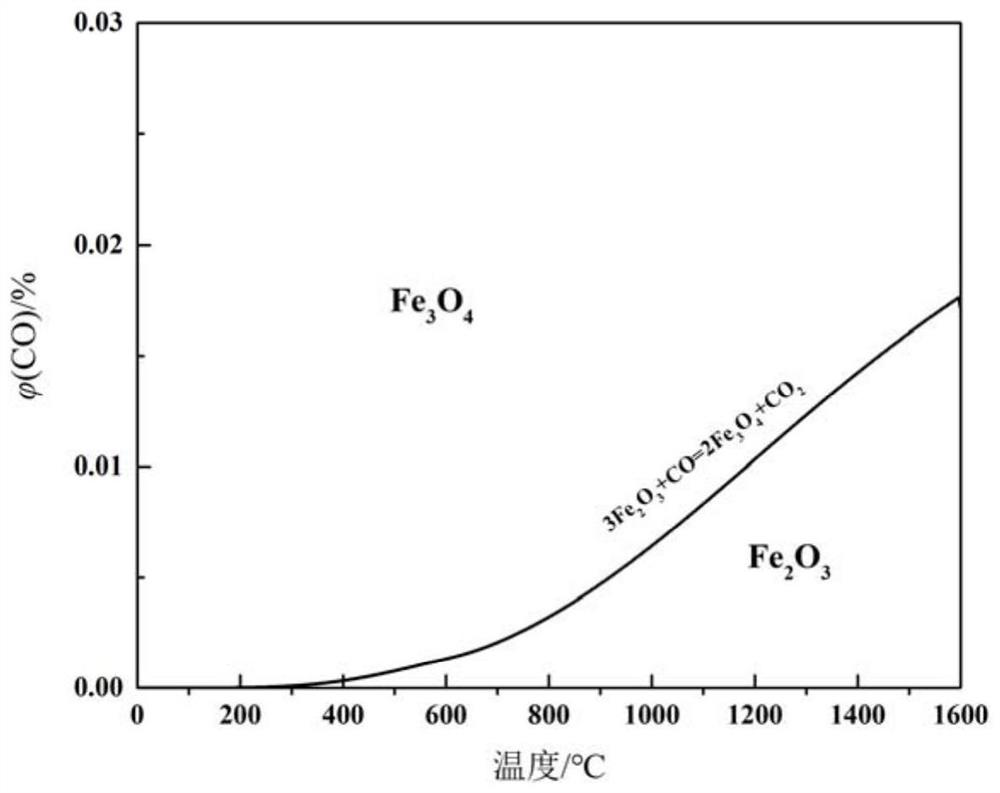

[0038] In this embodiment, in the bulk ore deposit, the Fe 2 o 3 The content is 50%-60%. Bulk ore can be sintered ore, hematite lump ore, pellet ore, etc. 2 o 3 Minerals that are mainly reducible substances such as calcium ferrite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com