Cyclone separator with powder shaping function

A technology of cyclone separator and powder, which is applied in the direction of swirl devices and devices whose axial direction of swirl can be reversed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

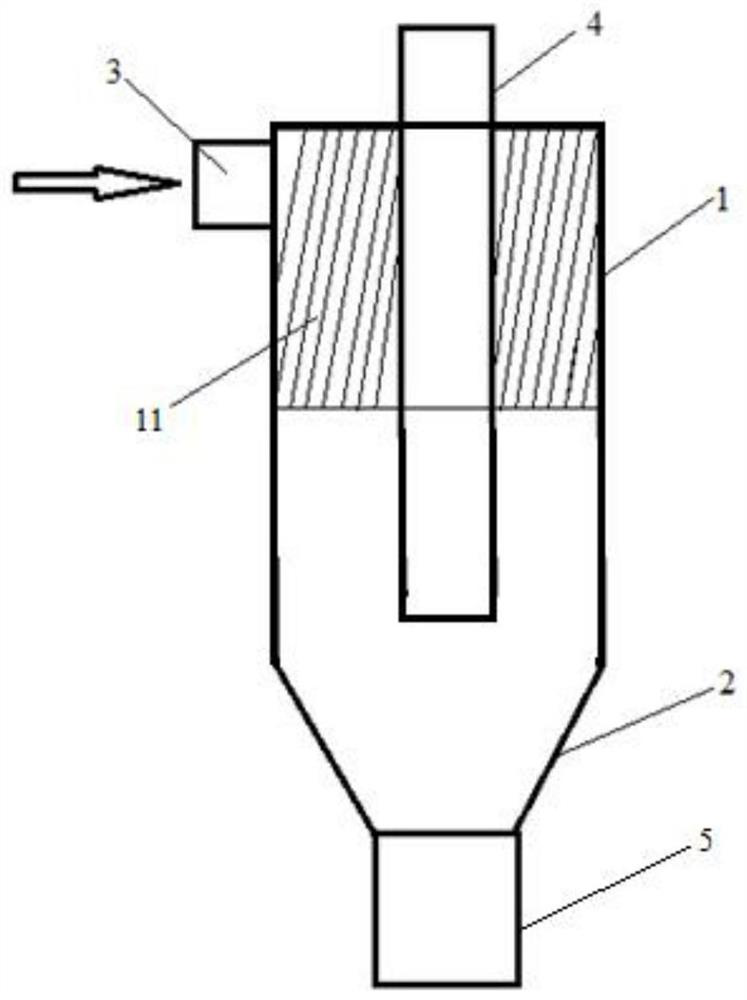

[0031] Such as figure 1 As shown, the cyclone separator with powder shaping function of the present invention includes a cylinder 1, a conical cylinder 2 arranged below the cylinder 1, and a powder discharge pipe at the bottom of the conical cylinder 2 5. An air inlet pipe 3 is provided along the tangential direction on the side of the cylinder body 1, and an air outlet pipe 4 coaxial with it is provided in the middle of the cylinder body 1; several parallel pipes are provided on the inner wall of the cylinder body 1. The first grinding line 11, the extension direction of the first grinding line 11 is perpendicular to the rotation direction of the airflow in the cyclone separator.

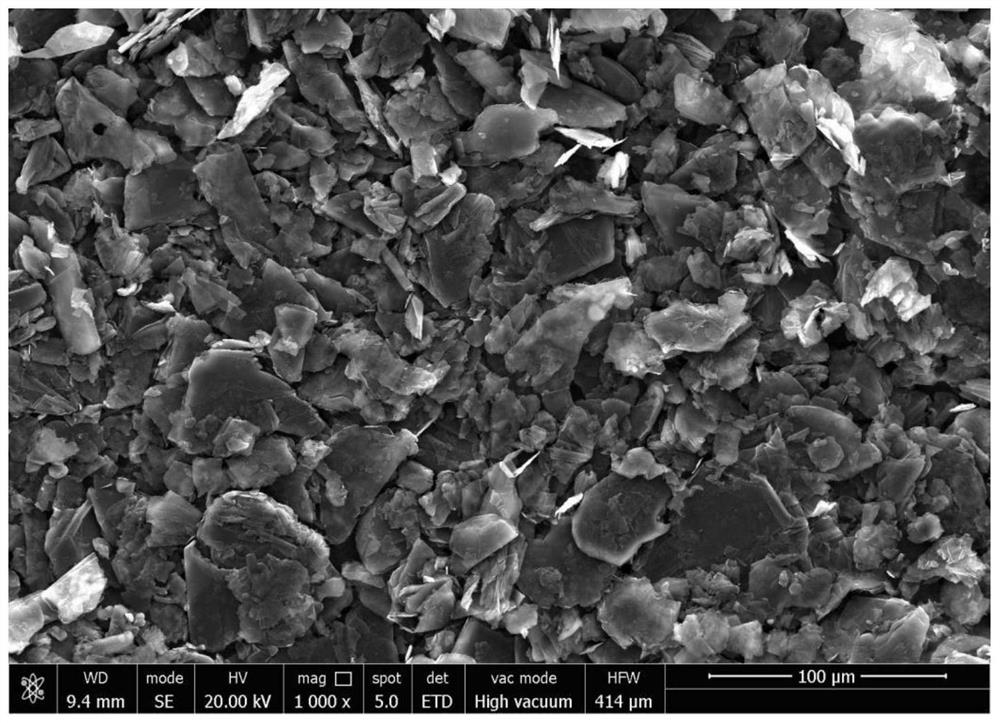

[0032] The cyclone separator with powder shaping function in this embodiment is mainly used for the shaping and separation of graphite particles widely used in the lithium battery field; the distance between the grinding line and the grinding line is 500 μm, and the grinding line The groove depth ...

Embodiment 2

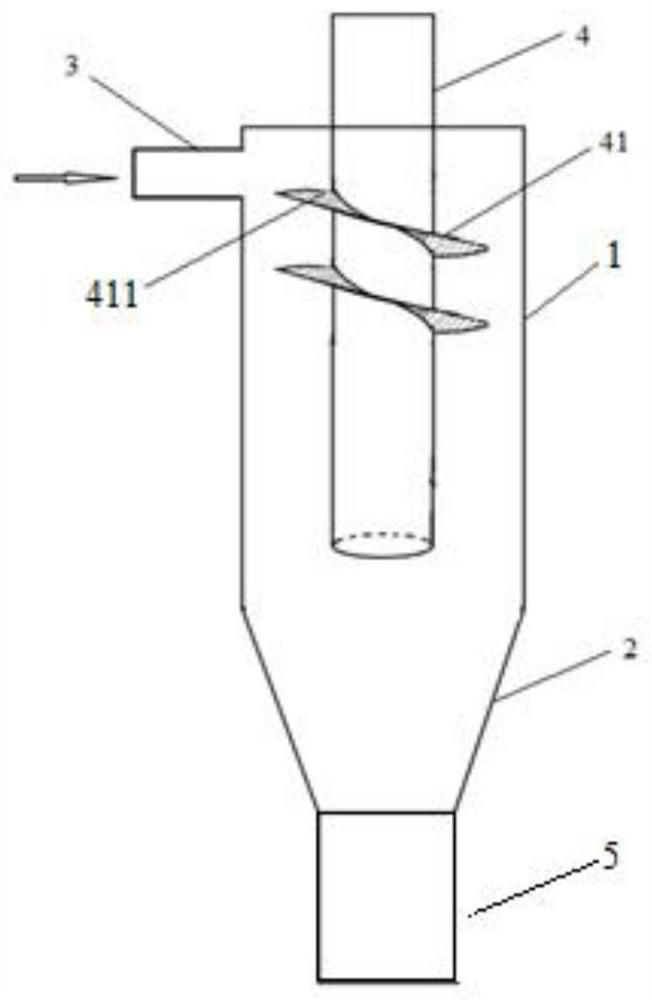

[0035] The cyclone separator with the powder shaping function concurrently as in embodiment 1. The difference is: the entire outer wall of the air outlet pipe 4 is provided with helical blades 41 with a pitch of 100mm, and the extension direction of the helical blades 41 is the same as the rotation direction of the airflow coming in from the air inlet pipe 3 on the inner wall of the cylinder body 1. The same; the helical blade 41 is provided with a second graining line 411 , and the extending direction of the second graining line 411 is perpendicular to the direction of the airflow coming in from the air inlet pipe 3 . The distance between the grain lines of the second grain lines 411 is also 500 μm, and the groove depth between the grain lines is also 500 μm. Others are the same as embodiment 1.

[0036] Using the cyclone separator with powder shaping function of this embodiment, under the same conditions as in Example 1, the graphite particles are shaped and separated, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com