Eccentric machining fixture for turning and grinding machine

A kind of turning grinding and eccentric technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of difficult to adjust the eccentricity, and achieve the effect of expanding the scope of application, improving the adjustment accuracy and improving the versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

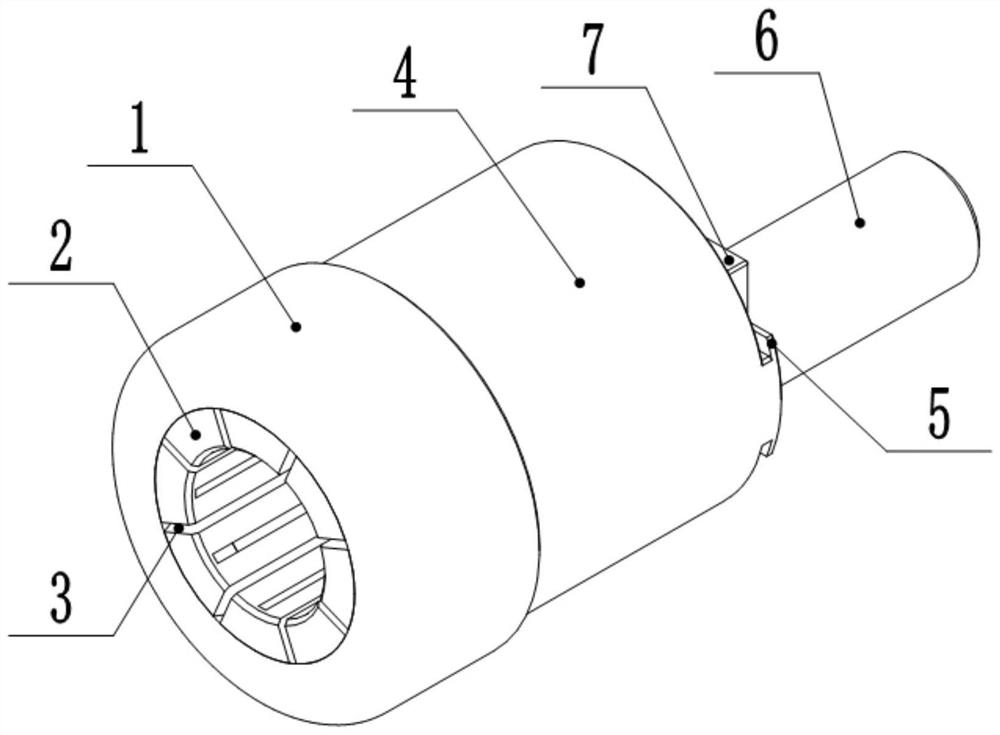

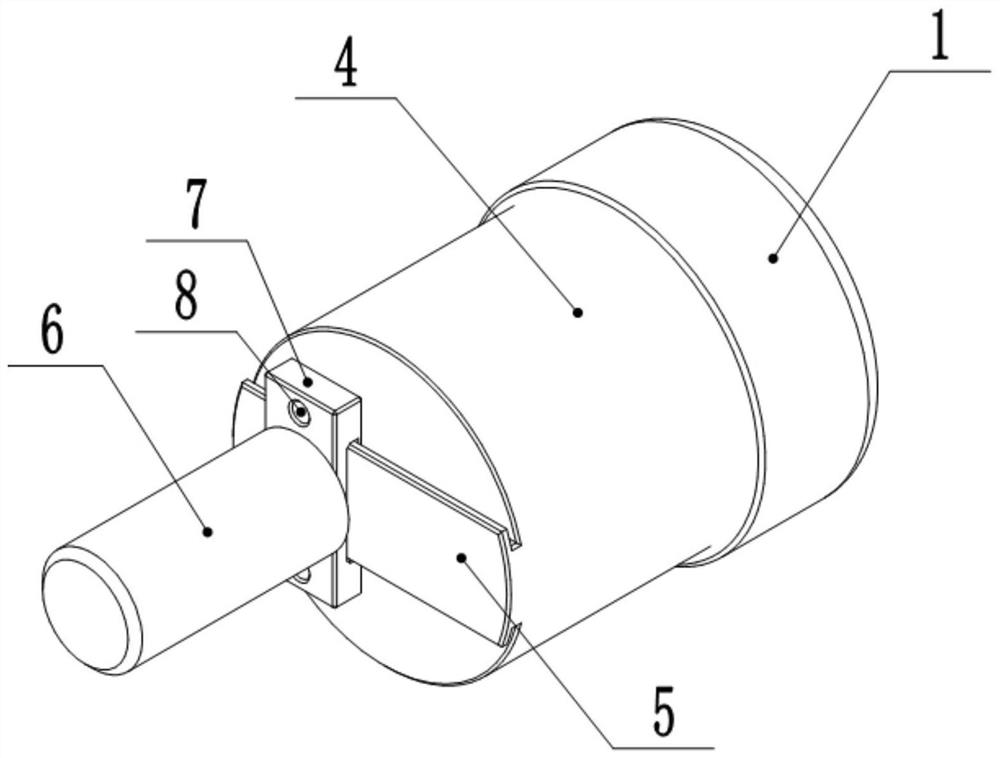

[0037] Such as figure 1 As shown, an eccentric machining fixture for a turning and grinding machine includes a clamping assembly for clamping a workpiece and an adjustment assembly for adjusting the eccentricity of the clamping assembly.

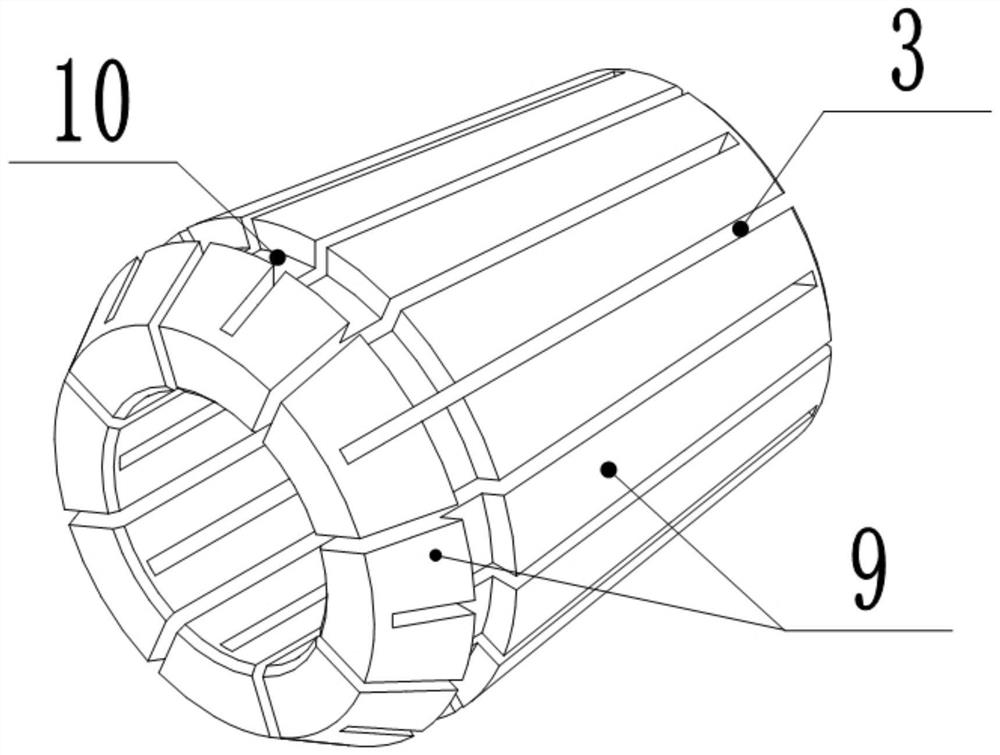

[0038] The clamping assembly includes a collet 2 for clamping the workpiece and a mounting piece for installing the collet 2, combined with image 3 As shown, the collet 2 includes a connecting portion 10 and a tapered portion 9 located at both ends of the connecting portion 10, and the taper directions of the tapered portions 9 at both ends of the connecting portion 10 are opposite, and the large diameter end of the tapered portion 9 is connected to the connecting portion 10, The inner diameters of the connecting portion 10 and the two tapered portions 9 are consistent, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com