Material backflow and shortage prevention pushing device for injection mold

A material return, injection mold technology, applied in the field of injection molds, can solve problems such as unqualified, injection molding quality decline, raw material deviation, etc., to avoid the decline of scalability and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

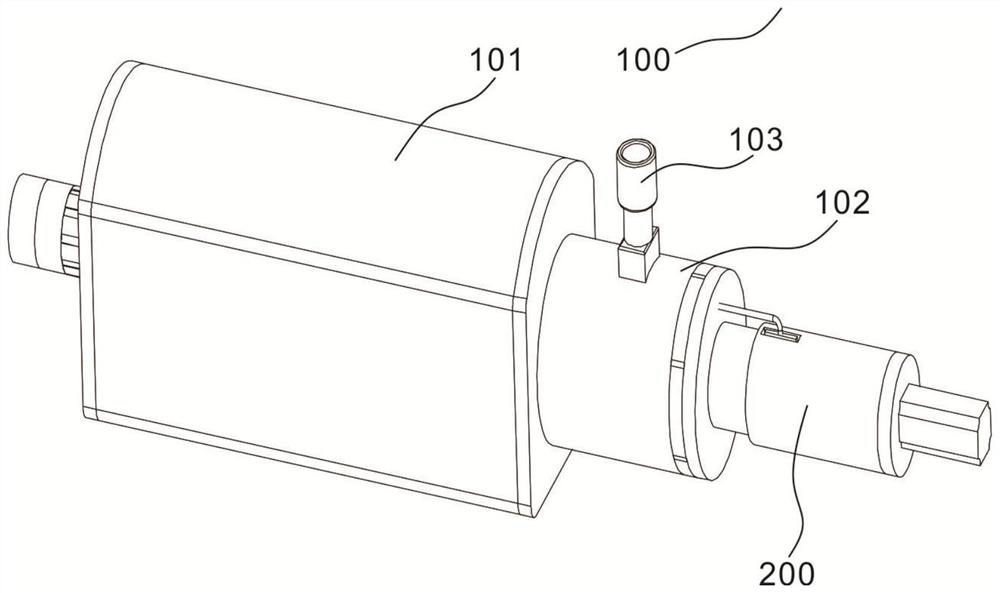

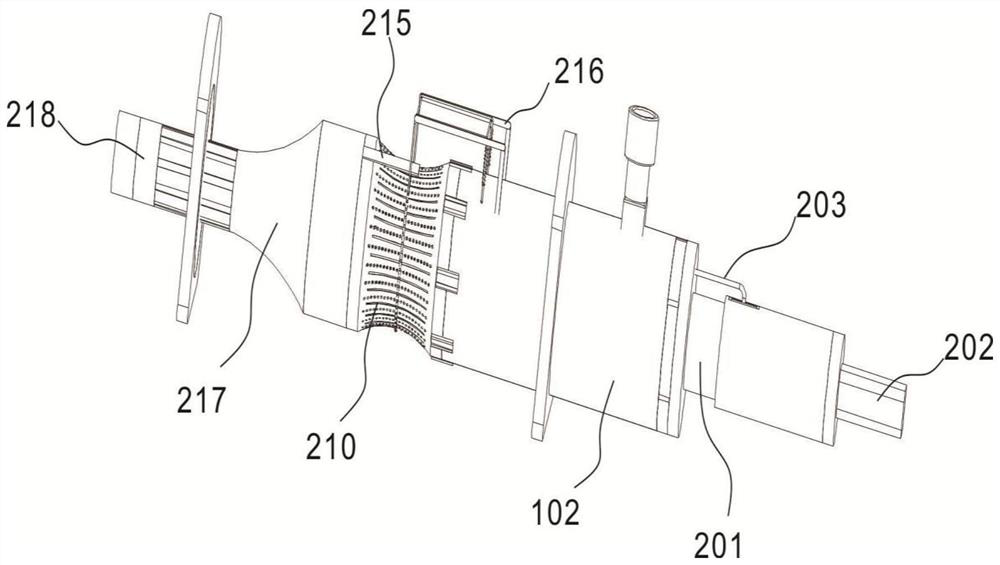

[0026] Example 1: Please refer to figure 1 , the present invention provides a propulsion device for preventing material backflow and lack of material for injection molds, including a base assembly 100, including a housing 101, the inner cavity of the housing 101 is inserted with a propelling cylinder 102, and the surface of the propelling cylinder 102 is inserted and connected with its inner cavity. Feed pipe 103; cut-off assembly 200, the cut-off assembly 200 is located in the inner cavity of the push cylinder 102, and the cut-off assembly 200 includes a fixed tube 201 inserted through the inner cavity of the push cylinder 102, and the end of the fixed tube 201 is provided with a push Cylinder 202 ; brush surface assembly 300 , the brush surface assembly 300 is arranged on one side of the cutting assembly 200 .

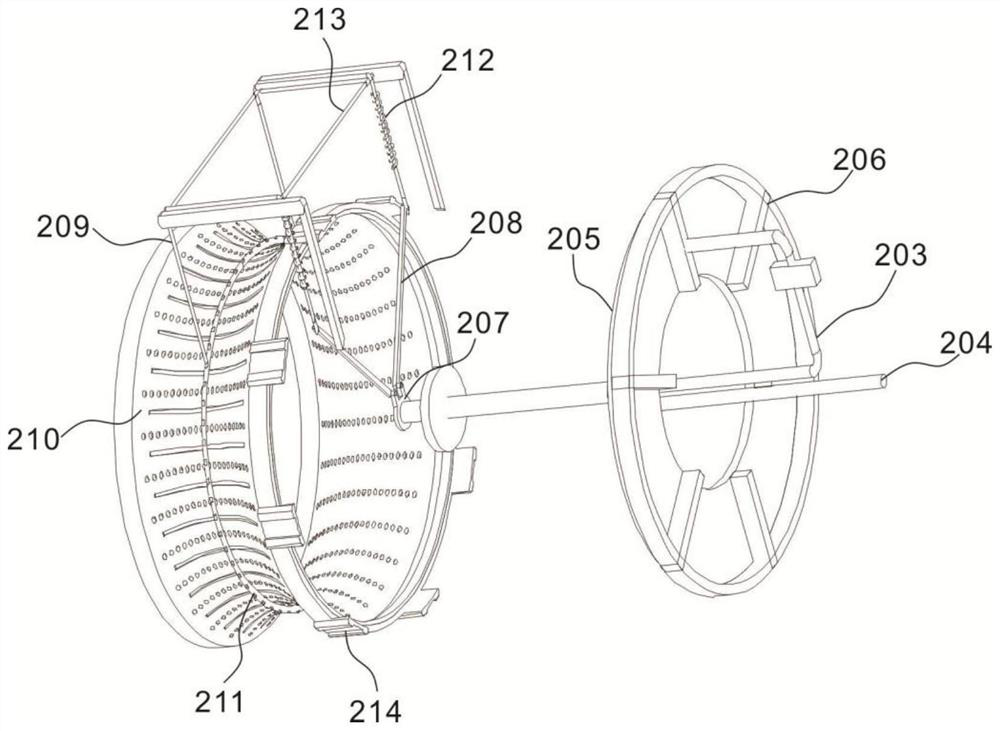

[0027] see Figure 2-4 , a U-shaped rod 203 is plugged into the fixed pipe 201, and one end of the U-shaped rod 203 is fixedly connected with the propulsion ring 20...

Embodiment 2

[0032] Example 2: Please refer to Figure 4-6 , the brush surface assembly 300 includes a bracket 301 fixed in the outlet pipe 218, a notch cylinder 302 is inserted horizontally on the surface of the bracket 301, and a strip-shaped notch is opened on the surface of the notch cylinder 302, and a cleaning plate 303 is arranged inside the notch cylinder 302, and the cleaning The surface of the plate 303 is densely inserted with brushes, and the end of the notch tube 302 is rotatably connected with a sleeve 304 sleeved outside the sleeve 304 .

[0033] see Figure 5 and Image 6 , the sleeve 304 is fixedly inserted with a rotating rod 305, the end of the rotating rod 305 is inserted into the inner cavity of the bracket 301, and the inner cavity of the bracket 301 is provided with a drive structure 306 fixedly connected to the output end and the end of the cleaning plate 303, The driving structure 306 is composed of a rotating cylinder and a pushing cylinder. The rotating rod 305...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com